What is a Shrink Wrapping Machine?

I believe you will have contact with the products wrapped by heat shrink film wrapping machine in your daily life, it is as small as sealing the film for bottles and as big as wrapping the mattress for our furniture. But do you really understand the heat shrink film machine, why you choose the heat shrink film machine instead of the transparent film wrapping machine, what was the difference between them before? Today, we take you to know it in depth.

Shrink Wrapping Machines Types

The shrink wrapping machine is made up of 2 parts, the first part is the cutting of the film and the second part is the heat tunnel shrink wrap machine. as you choose the film according to your product, the film in the shrink wrapping machine will be different if you want to know more about the film, you can read this article The article “Do you know how to calculate the shrink wrap film cost” will explain in detail which films are suitable for packaging your products. An edge sealer is a machine that cuts the film after your product has been transported on a conveyor belt to a certain location, usually based on the length*width*height of your product. Then the next step is to enter the shrink tunnel for shrinking. Our conventional types are Shrink Sleeve Machines, Bar Shrink Wrap Machine, Shrink Bundling Machine, Rotary Heat Shrink Packaging Machine, Flow Wrap Heat Shrink Packaging Machine, Pallet Shrink Packaging Machine and so on. Packaging Machine, pallet shrink wrap machine.

Among them: Shrink Sleeve Machine, mainly for packing beverages; l bar shrink wrap machine is used for packing large objects, such as home furniture, blankets, large gift boxes, and other products with large volume; Shrink Bundling Machine has similar advantages as pallet shrink wrap machine; Rotary Heat Shrink Packaging Machine is for rotary wrapping of film and then packaging; Rotary Heat Shrink Packaging Machine is for rotary wrapping of film and then packaging. Shrink Bundling Machine and pallet shrink wrap machine have similar advantages because they can pack products with pallets, for example, we commonly see 24 bottles of beverage pallets, and 12 bottles of Coca-Cola packaging; Rotary Heat Shrink Packaging Machine is a rotary wrapping film and then heat sealing; Flow Wrap Heat Shrink Packaging Machine is commonly used for sealing small packages, disposable instant noodles, CDs, DVDs, some skin care products, shampoos, shower gels and other common products.

How to use a shrink wrap machine?

In fact, the automatic shrink wrap machine works simply by wrapping a film around your product and then heat shrinking it. However, this step is to make your products avoid secondary contamination and achieve a sealed state, which makes the products by a better storage environment and delays the shelf life.

Shrink wrap machines are automatic packaging machines that consist of a combination of pneumatic components and mechanical devices controlled by a PLC and other peripheral circuits. The actuator of the machine is a cylinder. It is controlled by a two-position five-way solenoid valve to move forward and backward. The working position of the cylinder is detected by the magnetic switch and proximity switch and fed back to the PLC, which sends out control commands to the solenoid valve of the corresponding cylinder through the program to control the action of the cylinder.

Auto shrink wrap machine is generally used to protect the product after the first packaging. Give an example you will easily understand, aluminum cans of Coke, first of all, manufacturers will put the aluminum cans to Coke filling line, so that the liquid filling machine quantitative filling to the sealing machine sealing, sealing, you will get a small bottle of Coke, but because the Coke is the need to go from one place to another place of sale, so the manufacturer must quantitatively Coke packaged together, easy to calculate and transport, and then came to help 24 bottles of Coke loaded on a carton tray. A carton tray, is passed down the conveyor belt to the upper PE film Sleeve Machine and then cut into the heat tunnel shrink, and comes out is a box of Coke we can see in the shopping malls. commercial shrink wrap machine is a desktop shrink wrap machine, it’s Commercial shrink wrap machine is a desktop shrink wrap machine, which is a large-scale and high-efficiency packaging machine, not the same as the household shrink wrap machine, you may be able to shrink the film by heating the film in the household shrink wrap machine, but it is limited to the film with very small thickness.

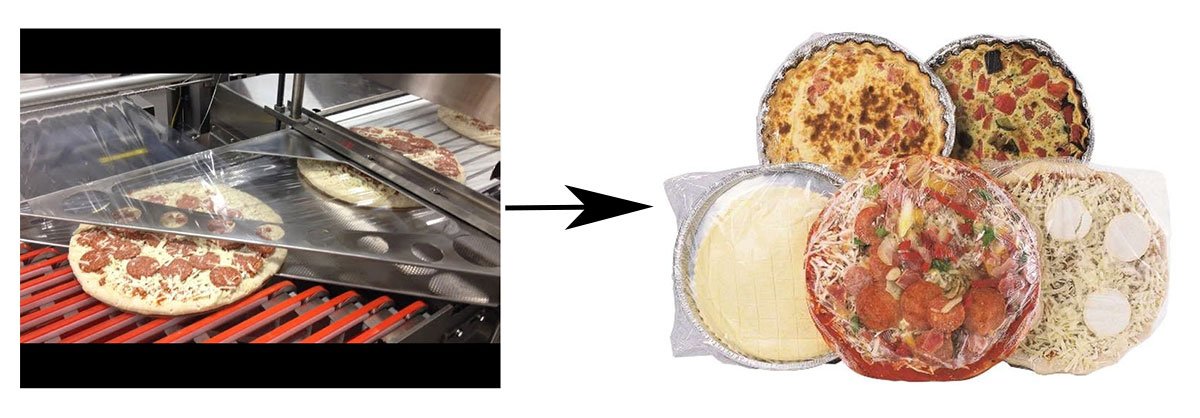

For example, the rapid development of RTE products nowadays has made it essential to have machines to wrap them. As an example, a pizza shrink wrap machine can pack semi-finished pizzas, due to the sticky nature of the pizza crust, the packaging process must be anti-sticking and the film is accessible to the food during the packaging process. Individual independent packaging, because the pizza crust is relatively soft, only after freezing will become hard, the manufacturer in order to better not let the pizza deformation, in each pizza plus a cardboard box, in the box packaging and then add a heat-shrinkable film packaging sealing, to avoid because of the wet water to the box to soften the result of the pizza by the second pollution. Of course, the environment for storing pizza also needs to be refrigerated. Such a set of procedures down, the packaging of pizza is used 2 times the heat shrink film machine.

Maybe some manufacturers feel the need for really multiple layers of protection.

A food product, flavor and correct storage will make your sales increase, because he directly affects the consumer’s concerns. pizza is now very common semi-finished food, but your consumer group is not tightly just a large corporate supply chain, more retail customers, retail customers need to provide him with even if I am now purchasing just a pizza, but I also need to A convenient and safe environment. As a producer, the development of the product is certainly important, but the second is to be able to solve some kind of problem for the consumer, cleanliness and hygiene, transportation methods, storage methods, these can not be ignored, may be the beginning of the investment will be big, but the long-term interests of your goal is to get more customer groups, rather than in order to control the cost of reducing the process, the sustainable development strategy is the vision and concerns that each manufacturer must have.

Shrink Wrapping Machine Benefit

Shrink wrap sealer machines can not only provide the film-cutting part but also provide efficient automation mode for manufacturers.

1. Reduce manual packaging, and improve production efficiency: Shrink Wrapping Machine front-end is connected to the packaging line, each product after the completion of packaging into the conveyor belt, edge sealing machine can quickly complete the product wrapping, shrink tunnel heat shrinkage process, automated procedures to improve efficiency, while reducing the need for manpower.

2. The finished product effect is uniform and beautiful: the products packed by the machine are tight and beautiful, with uniform standards, and the amount of film is also quantitative. Better protection of the product against dust and moisture.

3. Save the cost of film: the machine’s quantitative control of cutting film, and accurate control of different specifications of the product film dosage, compared with manual packaging can be more effective in saving materials, controlling the cost of raw materials.

4. Suitable for multiple sizes of products: Because the film width of the edge sealing machine is limited, but within the range of film width can be sealed, equivalent to a machine you can seal multiple sizes of products.

Application

Food industry

Food industry has many applications for shrink wrap machine, because it can effectively protect the quality of the products. food shrink wrap machine includes: pizza shrink wrap machine described above, instant noodle packaging, various kinds of punch box packaging, etc. If you want your products to be dust and moisture-proof, Shrink Wrapping Machine is your choice. If you want your products to be protected from dust and moisture, Shrink Wrapping Machine is the right choice for you.

Non-food industry

Shrink Wrapping Machine is widely used in audio, daily necessities, furniture, books, the electronics industry, etc. The most popular choice is Bath Wrapping Machine, which is the most popular choice among customers. Most of Customers choose the bath bomb shrink wrap machine, book shrink wrap machine, box shrink wrap machine, cellophane shrink wrap machine, carton shrink wrapping machine, CD shrink wrap machine, etc. Shrink Wrapping Machine is your best choice. machine, CD shrink wrap machine, DVD shrink wrap machine and so on. At the same time, the manufacturer will also specialize in customizing the heat shrink wrap machine for customers’ products.

Installation and maintenance

Installation

Before the machine is shipped, the manufacturer will debug the box according to your requirements, the purpose is for the machine to arrive, you can install the film and work directly, the manufacturer will provide tutorials for installing the film, so that you can realize the tutorials from a distance.

Daily maintenance

- After the machine works, remove the residue and dust on the conveyor roller, and keep the body clean and clean, the electrical parts should be kept dust-free, dry, and ventilated to avoid a long time of humid working environment, so in the planning of the machine placed in the place.

- Every day before going to work, you must check whether the nails of the movable parts are loose or not.

- Regularly check the lubricating oil in the gearbox of the conveyor motor to see if the operation is smooth.

- Make a comprehensive inspection of the overall performance of the machine once a month, and open the distribution box to remove dust and debris; chains and other running parts should be supplemented with lubricating oil in a timely manner.

- Before repairing the machine, you must turn off the power supply to access the machine; if there is really no mention of the problem, repair, should be repaired by professionals.

- If the machine is shut down for a long time, the power switch must be turned off to avoid prolonged energization.