Plastic Film Roll Packaging

- Customized available

- Clear print pattern

- Food grade material

- Strong tensile strength

- Suitable for various machines

Sembsun Plastic Roll for Packing

Most of our packaging machines need to use film roll packaging, such as our vertical packaging machine and flow wrapping machine. Film roll is the key to bag making. Good stretch wrap film will bring you a stable and smooth packaging process. Our automatic tray sealing machine also uses these films for sealing.

Secondly, the film roll can be used in automatic packaging film, cup sealing film, shrink film and all kinds of premade Pouch, such as 3-Side Seal Bags, Back Seal Bags, Stand Up Bag, Zipper Bags, Gusset Bags, Spout Pouches, Self Adhesive Bags, Flat Bottom Bags and others.

What Kind of Machine Can Use Plastic Roll Film

Different machine types of equipment use different types of roll films. You can try to check what kind of roll film your machine uses.

This side sealer machine uses the plastic shrink wrap roll. The stretch wrap roll can be customized according to the product you are packaging. The types of roll film include POF roll film, PE roll film, PET roll film, PVC roll film, and OPS roll film.

This machine mainly seals products with trays and cups. The types of roll film include PE roll film, PP roll film, PET roll film, aluminum foil composite roll film, and PA/PE composite roll film.

The types of roll film used by this machine include PVC, PET, PP, PP, cellulose sheet, PTP aluminum foil.

The film forming and bag making integrated packaging machine uses single-layer PE film, multi-layer co-extruded PE film, BOPP film, CPP film, PET film, PA film, aluminum foil composite film, PA/AL/PE composite film.

The roll films used in horizontal packaging machines include single material roll films such as OPP roll films, CPP roll films, and POF roll films; composite material roll films include PET/PE composite roll films, OPP/PE composite roll films, BOPP/CPP composite roll films, aluminum foil composite roll films, and paper film composite roll films.

The Application of Packing Plastic Wrap Roll Film

The application of roll film is becoming more and more extensive, and different roll film materials can meet your needs.

Our Roll Stock Film Features

The factory directly designs the drawings and customizes the roll film type that belongs to you.

After purchasing the packaging machine, you can choose the appropriate packaging materials, and pre-sales and after-sales services are in place

After the film design is confirmed, the film can be printed and synthesized and delivered to your city on time.

Environmentally friendly materials can be selected to protect the ecological environment and improve recycling rate

Customizable plastic film roll packaging

Our factory can provide customers with flexible production capacity according to the roll film size, roll film thickness, and printing pattern of different customers.

In addition, with our free technical support, we can optimize the customer’s packaging plan according to the customer’s product characteristics and provide different grades of roll film solutions to meet customers with different budgets. The roll film has a long service life and reduces the frequency of replacement, thereby saving our customers’ packaging costs.

Plastic Printed Laminated Packaging Film Roll

After the design of our printed packaging film roll is completed, the printing, laminating and slitting processes are completed simultaneously during the production process, which greatly reduces the intermediate links and saves labor and time costs. At the same time, we also customize the multi-color printing in the design, and the roll film with high-definition resolution can make the product packaging more beautiful. With our packaging machine, the finished bags with smooth sealing, firmness, and beauty are packaged.

Suitable for various machines

The machines suitable for roll film include coffee cup filling machines, vertical packaging machines, bedroom pillow machines, heat shrink film machines, blister machines and other machines. Filming and composite process, easy to heat seal, strong sealing.

Our Plastic Roll for Packing Production Line

Our customized roll film can produce roll film products with personality and brand characteristics according to the specific needs of customers, which is becoming more and more popular in the modern manufacturing industry. Our customized roll film can be provided to customers with different mixed roll film materials, flexibly improving the adaptability of roll film in this market.

Secondly, roll film is often used in combination with vertical packaging machines and horizontal pillow packaging machines. One packaging machine can solve the problem of film drawing and bagging, which greatly facilitates the needs of customers.

The minimum order quantity for our roll film is 500kg. After the customer designs the roll film type with us, we have the right to modify the design of the roll film. When the customer needs the roll film again, we can also quickly produce the roll film the customer needs, saving the time of redesign.

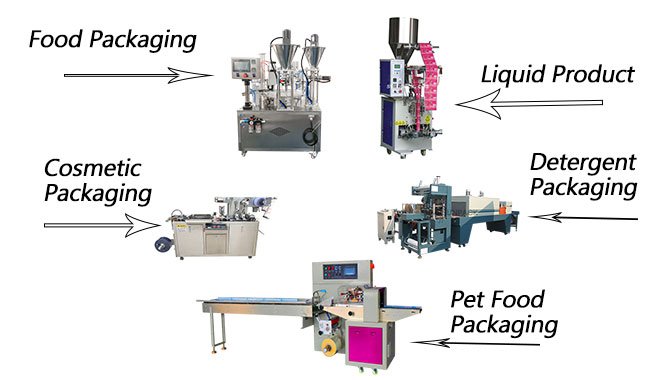

Other Machines for Pharmaceutical Packaging Line

How to Choose the Roll Stock Film for Your Machine?

POF film rolls

This type of film roll is environmentally friendly and non-toxic, with high transparency and high gloss, which can clearly show the appearance of the product; it has a large shrinkage rate of up to 75%, good flexibility, and can adapt to products of various shapes; it has good welding performance and high strength, and is suitable for a variety of packaging methods; it has good cold resistance and can maintain flexibility at -50℃.

It is well used in the plastic packaging of automotive products, plastic products, stationery, books, electronics, circuit boards, MP3, albums, crafts, photo frames and other wooden products, toys, pesticides, daily necessities, food, cosmetics, canned beverages, dairy products, medicines, and videotapes.

PE film rolls

It has good flexibility, strong impact resistance, and is not easy to break; it has a high shrinkage rate and can wrap the product well; it has good puncture resistance and protects the product from wear and tear in the external environment during transportation; it is cost-effective and relatively low in price; it has good temperature resistance.

In daily life, you can find combination packaging and cluster packaging of liquid foods such as beer, beverages, bottled water, mineral water, condiments, edible oil, etc. It is also suitable for pallet packaging in large-scale manufacturing products and logistics transportation.

PET film roll

It has good physical and mechanical properties; it is easy to recycle, non-toxic, odorless, and meets environmental protection requirements; it has good barrier properties against oxygen and water vapor, and can extend the shelf life of products.

It can be used for packaging of beverages, dairy products, convenience foods, some electronic appliances, metal products, etc. in daily life.

PVC film roll

It has high transparency, good gloss, and high shrinkage rate; the price is relatively low, and there are many spot sizes.

In the past, it was widely used in the packaging of various products, such as daily necessities, toys, stationery, etc., but due to environmental protection issues, it has gradually been replaced in some fields with high environmental protection requirements. However, it still has certain applications in some industries that are cost-sensitive and have relatively low environmental protection requirements, such as some low-end small commodity packaging.

OPS film roll

It meets environmental protection requirements and can be recycled and reused; it has good gloss and transparency, good printing performance, and extremely high printing resolution; the lateral shrinkage rate can be as high as 80%, and it can fit tightly with containers of various shapes.

It is particularly suitable for label packaging of beverages, food and other products, which can highlight the image of the product on the shelf, and can also be used for skin packaging of some packaging containers with unique shapes, such as special-shaped bottles.

PE film roll

Single-layer PE film roll: has good flexibility, low-temperature resistance and heat sealing performance, non-toxic and tasteless. Vertical packaging machine is often used to package bread and other foods that do not require high barrier properties, as well as daily necessities, stationery, etc.

Multi-layer co-extruded PE film roll: better comprehensive performance, with higher strength, barrier, and puncture resistance.

PP film roll

BOPP film roll: has high transparency, high mechanical strength, good moisture resistance,e and water resistance. Vertical packaging machines are often used as printing layers for food packaging such as candy and biscuits, as well as daily necessities, cosmetics, etc.

CPP film roll: good heat sealing performance, often used as the heat sealing layer of the composite film roll, and after being compounded with BOPP and other materials, it is used for food, daily necessities, etc. packaging.

PET film roll

Ordinary PET film roll: high transparency and good toughness. Vertical form fill seal machines can be used for food packaging such as beverages and sauces.

Aluminized PET film: A layer of aluminum is coated on the surface of PET film, which can effectively block oxygen, water vapor, light, etc., and has good fragrance preservation and light-shielding properties. It is often used for packaging food, medicine, cosmetics, etc. with high requirements for freshness preservation and barrier properties.

PA film roll

Pure PA film: Also known as nylon film, it has good puncture resistance and can maintain good performance in a wide temperature range. It can be used for vacuum-packed meat, pickles, nuts, and other food packaging and industrial product packaging with high barrier properties.

PA composite film: After being compounded with PE, CPP, and other materials, the comprehensive performance is better, and different composite structures can be selected according to different packaging requirements. For example, PA/PE composite film has both the barrier properties of PA and the heat-sealing properties of PE.

Aluminum foil composite film

PET/AL/PE composite film: It is compounded by PET, aluminum foil, and PE. PET provides good mechanical properties and printing adaptability, aluminum foil has excellent barrier properties, and PE is used as a heat-sealing layer. Commonly used for packaging of high-end food, health products, medicines, etc.

PA/AL/PE composite roll film: PA as the outer layer, providing good flexibility and barrier properties, aluminum foil as the middle barrier, PE heat seal, suitable for product packaging with high requirements for barrier properties, flexibility, and heat sealing performance, such as some high-end cosmetics, electronic products, etc.

Single material roll film

OPP roll film: colorless, non-toxic, with high tensile strength and good transparency, easy to burn, suitable for packaging of various foods, beverages, home appliances and hardware products, etc., mainly plays the role of protecting products, and has high packaging efficiency.

CPP roll film: excellent heat resistance, can be used in hot filling, cooking bags, aseptic packaging and other fields, excellent acid resistance, alkali resistance, grease resistance, safe contact with food, will not affect the flavor of the food inside, flow wrapping machine is used for bread product packaging.

Composite material roll film

PET/PE composite roll film: high transparency, good oxygen barrier, heat resistance and cold resistance are also very good, especially suitable for inflatable packaging of bread, cakes and other foods, and can also be used as packaging bags for quick-frozen foods and cooking foods.

OPP/PE composite roll film: very good air and moisture barrier, good oil resistance, suitable for packaging of green tea, cooked foods, oil products, etc.

BOPP/CPP composite roll film: It has the highest transparency and good moisture barrier performance among all composite films. Flow wrapper packaging biscuits, instant noodles and other dry foods and fast food are the most commonly packaged products in our daily life.

Aluminum foil composite roll film: Such as PET/AL/PE, PA/AL/PE, and other structures. It has excellent barrier properties and is often used for packaging of foods with high requirements for freshness, high-end cosmetics, medicines, electronic products, etc.