Sembsun Double Chamber Vacuum Packaging Machine

A highly efficient packaging device designed for industries such as food, pharmaceuticals, and chemicals.

- Two independent vacuum chambers

- Easy to operate and offers stable performance

- Widely applicable for vacuum packaging

- Vacuum pack machine used by Food

Sembsun Double Chamber Vacuum Packaging Machine

Our double chamber vacuum sealer is an advanced and efficient packaging solution designed for vacuum-sealing products across industries such as food processing, pharmaceuticals, and chemicals. Its robust design and dual-chamber functionality allow it to deliver high productivity and reliable performance, making it an ideal choice for businesses looking to optimize their packaging processes.

It can package larger items as well as handle multiple smaller items simultaneously. It is suitable for large-scale continuous production needs, offering high work efficiency, and can be equipped with a gas-flushing function.

Our Double Chamber Vacuum Packaging Machine is an excellent investment for businesses seeking high efficiency, flexibility, and reliability in their packaging operations. Its dual-chamber design and advanced features make it a standout solution for improving productivity and preserving product quality.

Know More About of Our Double Chamber Vacuum Configuration

- Double Chamber Part

- Control Panel

- Technical Parameters

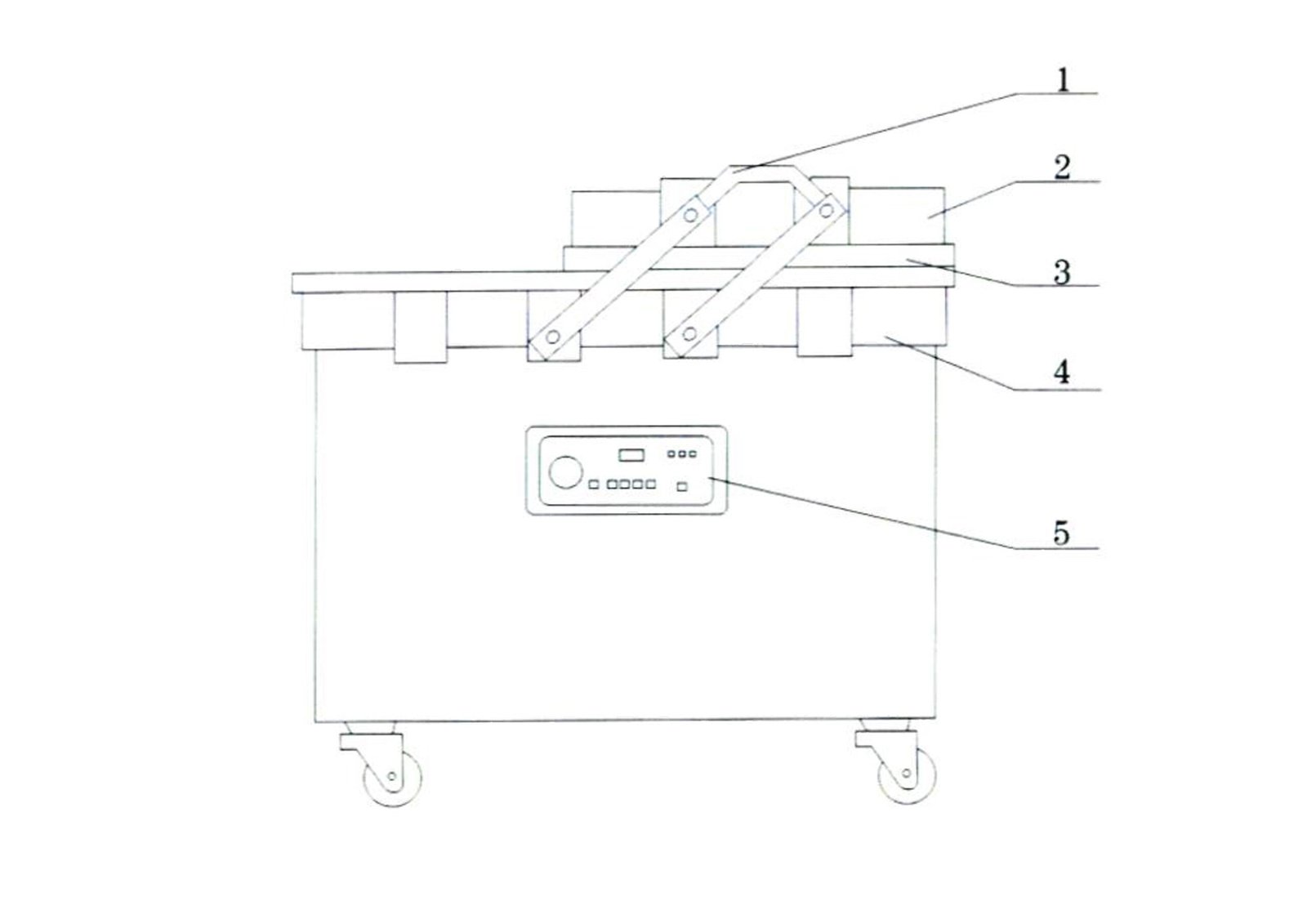

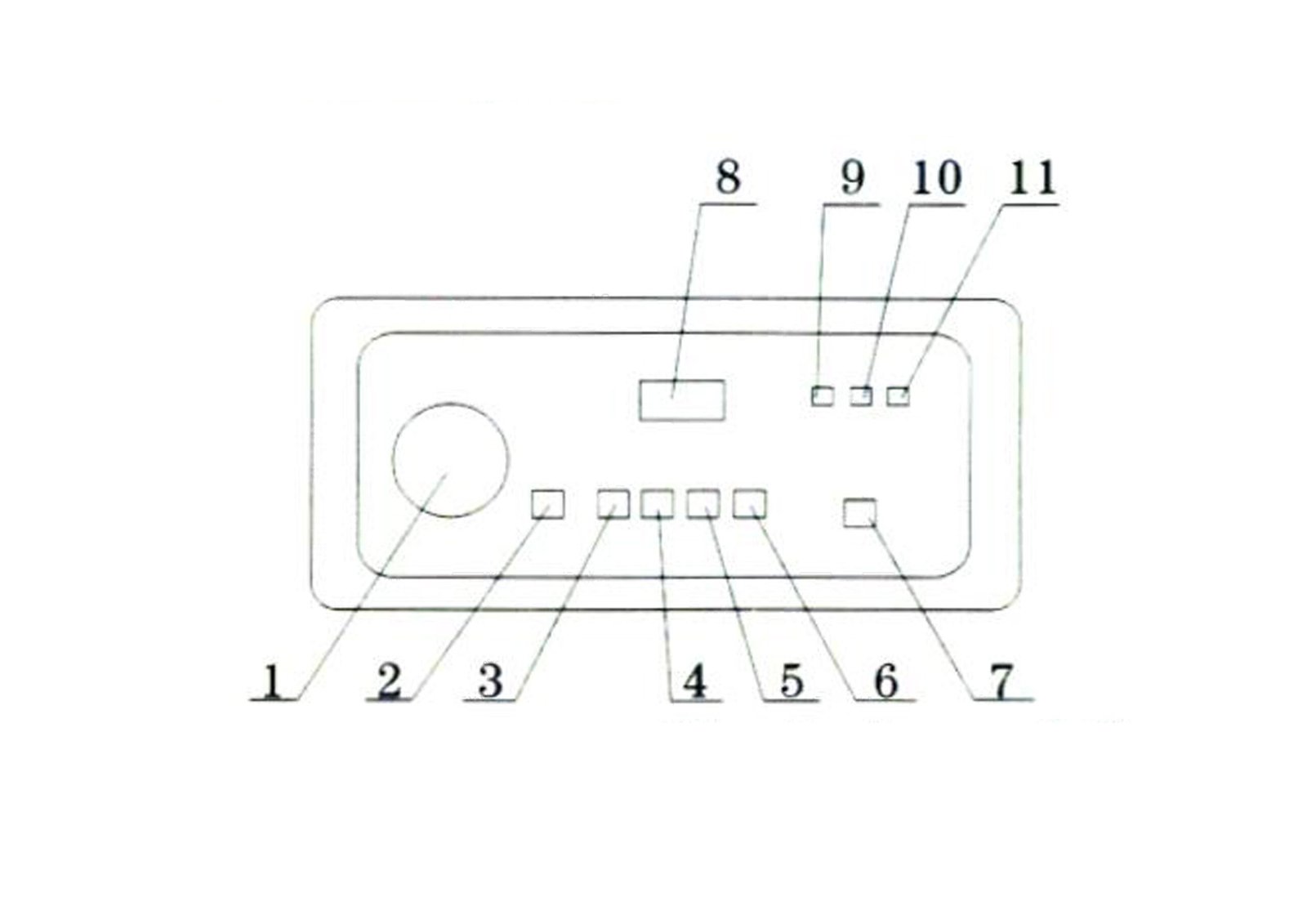

External and operation panel arrangement figure

- Swing rod

- Upper working chamber

- Sealing ring

- Lower working chamber

- Control panel

- Vacuum indicator meter

- Stop knob

- Vacuum time setting knob

- Sealing time setting knob

- Time increase knob

- Time decrease knob

- Sealing temperature setting knob

- Vacuum & sealing time indicator

- Low-temperature indicator

- Middle-temperature indicator

- High temperature indicator

Technical parameters.

1. The scope of Air-extraction time:0sec.-99sec. Error rate: <0.1%

2. The scope of Thermal-sealing time: 0.0sec.-9.9sec. Error rate:<0.1%

3. Temperature enactment: High, middle, low.Temperature

4. Constant temperature: Fixation 2 sec.

5. Deflation-air: Fixation 2sec.

| Model | D-400/2SB | D-500/2SB | D-600/2SB |

| Voltage | AC380V/50Hz AC220V/50Hz | AC380V/50Hz AC220V/50Hz | AC380V/50Hz AC220V/50Hz |

| Motor power | 900W | 1800W | 2000W |

| Sealing power | 500W | 800W | 1000W |

| Ultimate vacuum pressure | 1KPa(mbar) | 1KPa(mbar) | 1KPa(mbar) |

| No.of sealing bars for each chamber | 2pcs | 2pcs | 2pcs |

| Chamber dimension(L*W*H) | 490*470*150mm | 600*540*150mm | 700*540*150mm |

| Sealing length | 400mm | 500mm | 600mm |

| Sealing width | 10mm | 10mm | 10mm |

| Vacuum pump rate | 20m³/h | 20*2m³/h | 20*2m³/h |

| Material for vacuum chamber | Stainless stee 304 | Stainless stee 304 | Stainless stee 304 |

| Dimension(L*W*H) | 1000*570*930mm | 1260*600*1000mm | 1460*600*1000mm |

| Net weight | 140kg | 186kg | 245kg |

| The center distance between two sealing bars | 380mm | 440mm | 440mm |

Sembsun Double Chamber Vacuum Packer

Upper Working Chamber

The upper working chamber of the Double Chamber Vacuum Packaging Machine is a key component designed for efficient vacuuming and sealing operations. Positioned above the machine base, it plays a critical role in creating airtight packaging. Our upper chamber is made of food-grade 304 stainless steel, ensuring excellent sealing performance and high durability, making it ideal for food safety and industrial applications.

Vacuum tube

This is the vacuum tube, which is an essential component of the Double Chamber Vacuum Packaging Machine, responsible for transferring air out of the packaging chamber during the vacuuming process. It plays a critical role in achieving optimal vacuum levels and ensuring airtight sealing.

Machine Features Advance

Double Chamber Vacuum Packaging Machine Applications

- Food Industry

- Pharmaceutical Industry

- Chemical Industry

- Electronics Industry

- Textile Industry

- Perishable Goods: Extends the shelf life of meat, poultry, seafood, and dairy products by preventing spoilage and microbial growth.

- Dry Goods: Ideal for packaging nuts, grains, coffee, tea, and snacks to maintain freshness and prevent moisture ingress.

- Processed Foods: Used for vacuum-sealing ready-to-eat meals, sauces, and frozen foods for better storage and transportation.

- Medical Instruments: Ensures sterilization by vacuum-sealing surgical tools and devices.

- Medicinal Products: Packages pharmaceutical powders, tablets, and herbal medicines to prevent contamination and preserve efficacy.

- Industrial Powders: Suitable for vacuum-sealing fine powders and granules to avoid exposure to moisture and air.

- Liquid Chemicals: Prevents spillage and oxidation of sensitive chemicals during storage and shipping.

- Component Packaging: Protects sensitive electronic parts, such as microchips and circuit boards, from moisture and static damage.

- Tool Storage: Ensures rust-free storage of tools and precision instruments.

Compressed Packaging: Used for vacuum-compressing garments, quilts, and other textile products to save space during transportation.

Related Machine Model

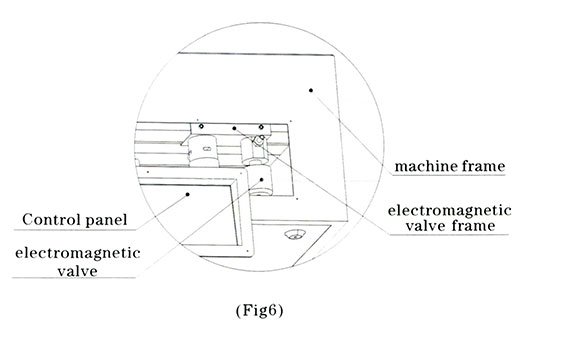

At first,to unload the control panel, then unload the electromagnetic valve framethe vacuum room, finally take the electromagnetic valve and change it.(Fig6)

Remark: same electromagnetic valve.

Based on the regulations, the vacuum pump manual maintains, and filling oil into the pump regularly. And reverse the pump us not permitted to avoid damaging the pump, and spurting the oil on the vacuum room.

Checking the things on the teflon cloth on the sealing stand, it’s flat or not, to keep the strength of sealing.

If the machines are malfunctioning, you must power them, essentially press the emergency stop button, open the cover after bleeding the air, and finally power off the machine, check it, and repair it.