Sembsun Food Packing Machine factory

Our food packaging machines help many suppliers complete their packaging solutions. Food packaging machines are one of the best choices for small businesses. The quality of packaging machines is strictly produced according to international standards, and with our patented inventions, we provide professional food packaging solutions for different customers.

In addition, you only need to provide the size of your product, and our 15 years of experience can quickly tell you what you need to pay attention to and respond efficiently.

Food Packaging Machine Application

Many food manufacturers choose our packaging machinery to transform from large-scale labor to mechanized batch production, increasing production efficiency and improving packaging quality. The snack industry, baking industry, candy packaging, puffed food packaging, pre-prepared food packaging, dried fruit packaging, fresh fruit and vegetable packaging, etc., greatly provide these industries with high-quality and efficient packaging equipment.

Sembsun Automatic Packaging Machine Features

Every machine is manufactured and shipped in strict accordance with national standards

The equipment is of good quality, affordable, durable, and easy to operate

Export certificates can be provided, so you don’t have to worry about export issues

Return orders from customers increase every year, honesty and trustworthiness

Food Material Feeding Machine Equipment

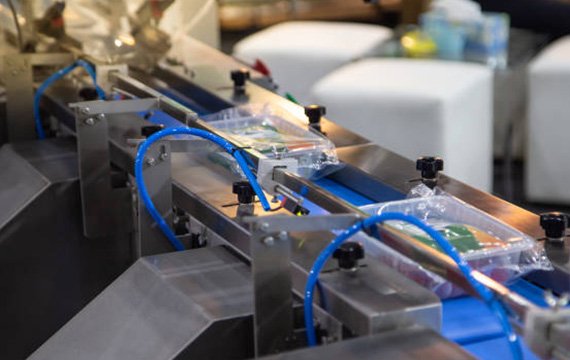

Sembsun food packaging machine maintenance plan, generally recommends our customers to use feeding equipment to transport video materials to the weighing device. For food packaging, food safety is important, reducing manual secondary contact will effectively reduce contamination from the source.

Secondly, food-feeding equipment can reduce the weight of the packaging machine on the material, avoiding the weight of the material covering the machine for a long time.

Squeeze the air out of the package

In the Sembsun flow wrapping food machine, we can add a pressing brush and sponge to block the lighter and loose products. This effectively suppresses the height of the product. On the one hand, it can avoid the loose seal caused by the material being too high. The sponge is the simplest exhaust method for flow wrapping machines and is cheap.

Vacuum packed food

For some meat and easily oxidized foods, in order to better package and extend the storage period, the design of vacuum packaging is to first put the material into the bag, and then seal it. At the same time, a tube is inserted into the bag to extract the gas, and then seal it.

Sembsun generally has two types of food vacuum methods. The vertical packaging machine and the horizontal bag packaging machine use a tube to vacuum, while the rotary bag packaging machine uses a vacuum chamber to vacuum.

Sembsun Automatic Food Packaging Line Components

The most important thing about food packaging is food safety. In the process of packaging and sealing, it is sometimes inevitable that other metal objects will fall. However, after the packaging is sealed, metal detection can be used to remove packaging mixed with metal products and remove problematic packaging. This is a process that cannot be replaced by manual labor.

Food production lines tend to be more automated, adding palletizers can reduce manpower input and reduce secondary contamination caused by multiple people’s contact. Palletizers are operated in real-time according to the program, which makes them more maneuverable.

What are you most worried about food packaging machines?

Our sales team will advise you on what to pay attention to when buying a machine in China for the first time, such as the quality of the factory, whether it can provide a variety of packaging equipment, and other matters. Help you deal with problems from ordering, machines, shipments, documents, and other details. The price of the machine is based on the choice of machine equipment. The stability of the motor equipment is one of the foundations for maintaining the stable operation of the machine. We will realistically introduce the categories and choices of motors because we have 15 years of experience. The choice of motors is the most important. After all, we are giving customers highly stable packaging equipment.

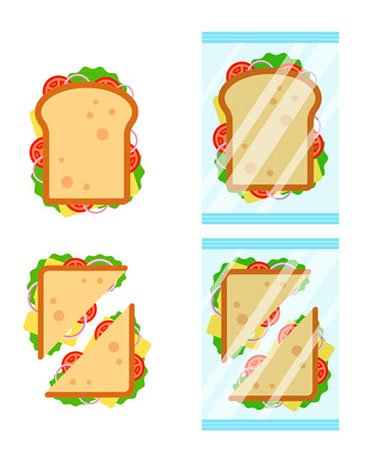

Each of our food packaging machine models has a range of packaging bags. If the bag size designed by your factory is within this range, it is compatible. For debugging, your factory employees only need to follow our instructions to debug and get started quickly. If you are worried about the long machine adjustment time for your first packaging investment, we will have professional technicians to provide on-site guidance later.

Related Product

People Also want to know more about Food Packaging

Food packaging refers to sealing food in specific containers or packaging materials. This process helps protect food, making it easier to transport and sell. But why is food packaging so indispensable in the modern food industry? Here are the key reasons:

1. Protects Food Quality

Good food packaging enhances the quality of your product by:

Shielding food from air, moisture, and microorganisms, helps prevent spoilage and extends shelf life.

Protecting food from physical damage like crushing or deformation, ensuring a better presentation for sales.

Specialized methods, such as:

Vacuum packaging: Removes air inside the packaging to create a vacuum environment.

Modified atmosphere packaging: Adjusts the gases inside the package to preserve food, commonly achieved with machines like the automatic tray packaging machine.

2. Includes Production Information

High-quality food packaging equipment not only seals food but also prints essential details, such as logos and production dates.

Including production dates or QR codes on food packaging ensures traceability, which is critical for food safety and quality checks.

3. Convenient to Carry and Use

Modern food packaging emphasizes convenience:

Individual packaging makes it easier for consumers to carry and ensures portion control, preventing waste.

Plastic food packaging often includes features like easy-to-open seals or reclosable options, which are highly favored by consumers for their usability and practicality.

These features improve material efficiency and align with consumer preferences.

Why Do We Need Food Packaging? Food packaging is not just a societal demand but also a standard for improving quality of life. Packaging machines play a crucial role in meeting this demand, offering better food protection, usability, and traceability while enhancing the overall consumer experience.

The fact that food packaging is getting smaller and smaller in the market is actually to meet society’s needs. Because people have such needs, creators will create food that can be packaged in small bags.

1. Meet the needThe fact that food packaging is getting smaller and smaller in the market is actually to meet society’s needs. Because people have such needs, creators will create food that can be packaged in small bags.

1. Meet the needs of market consumers

Small bag packaging can provide consumers with a more convenient way to use it. Food is a fast-selling product, and the corresponding food packaging has also become one of the fast-selling packaging, which can adapt to the current pace of life. Small packages of snacks, ready-to-eat foods, and other small bags of food packaging are very suitable for enjoying on the go or in a short time.

At the same time, personalized consumption is also a good reflection of the trend of small-bag food packaging. Small packaging better meets the taste preferences and eating habits of different consumers, and one person can also try different flavors.

2. Quantitative small bag packaging can control the amount

For some high-calorie foods, such as butter, chocolate, etc., small packaging helps consumers control food intake and avoid excessive consumption.

3. Advances in packaging technology

Small packing machine for food products can make food in small bags, while ensuring quality and output, making small packaged food more efficient and economical. Now the technology of combining small bags into large bags with vertical packaging machines can make packaging production more efficient.

So, why small bag packaging has become a trend because the economic benefits are in line with consumer needs.s of market consumer.

Factors Affecting the Shelf Life of Vacuum-Packaged Foods

The shelf life of vacuum-packaged food depends on various factors, such as the type of food, processing methods, storage conditions, and packaging techniques. Below is an approximate guide for different types of vacuum-packaged foods:

1. Fresh Meat and Seafood

Non-frozen: Typically lasts 3 to 5 days.

Frozen vacuum packaging: Can last several months (e.g., beef: 6 to 12 months, chicken: 3 to 6 months, fish: 3 to 8 months).

2. Cooked and Ready-to-Eat (RTE) Foods

Refrigerated: Usually lasts 3 to 7 days.

Frozen: Can last 1 to 3 months.

3. Vegetables and Fruits

Non-frozen: Leafy vegetables can last 1 to 2 weeks, while root vegetables can last 2 to 4 weeks.

Frozen: Can last 8 to 12 months.

4. Bread and Baked Goods

Room temperature: Typically lasts 3 to 7 days, depending on the recipe and humidity.

Frozen: Can last 2 to 3 months.

5. Dry Goods and Grains

Room temperature: Items like rice and noodles can last 6 to 12 months.

Frozen: Can last longer under extreme conditions (e.g., to prevent pest infestation).

6. Pickled and Fermented Foods

Room temperature: Items like salted fish or cured meat can last several months to a year.

Refrigerated: Items like pickles or sauerkraut can last several months.

Key Factors Influencing Shelf Life:

a. Processing Method: Foods treated with high-temperature sterilization last longer than those with simple vacuum packaging.

b. Storage Temperature: Low temperatures (e.g., refrigeration or freezing) can inhibit bacterial growth and significantly extend shelf life.

c. Initial Quality: High-quality, fresh ingredients last longer.

d. Packaging Seal: Proper vacuum sealing ensures a low-oxygen environment. Always check for damage or leaks in the packaging.

Using a vacuum packaging machine is essential to create a reliable seal and maximize food preservation.

Home-use food packaging machines are very popular, as many people enjoy the DIY process or want to preserve food better. Common homemade food items include handmade candies, chocolates, cookies, and more. Corresponding small packaging machines for these products include:

- Shrink Wrap Machine: Ideal for wrapping and sealing products for a professional appearance and protection.

- Candy Wrapping Machine: It is designed for wrapping small handmade candies.

- Pickle Packing Machine: Used for sealing pickled items in jars or pouches.

- Homemade Soap Filling Machine: Suitable for liquid soaps, lotions, or similar homemade products.

- Blister Packaging Machines: Perfect for packing items like candies or small baked goods in individual compartments.

- Homemade Chocolate Packing Machine: Specially designed for wrapping chocolates in foil or other materials for freshness and presentation.

These machines make it easier to package homemade items efficiently and professionally while preserving their quality.

Before the invention of automatic food packing machines, people relied on natural materials to manually pack food. For home use, one common method was using water to isolate food from air, preventing oxidation. For instance, marinated fish would be placed in a basin, covered with a water-filled container to push out air gaps and extend storage time.

Additionally, salt was often used to preserve fresh meat. However, compared to modern home food vacuum packing machines, this method altered the meat’s original freshness and flavor.

With the invention of plastic, people began using plastic bags to package food. Thanks to its excellent physical properties, plastic provides better food protection, making food packing more secure and reliable.

The development of plastic food packaging machines introduced more efficient ways to package various foods. For example:

- Bread, pastries, and snacks like cookies: These can be packed using vertical packaging machines, which handle automatic weighing, filling, bag forming, and sealing in one integrated process.

- Frozen foods: These are often packed using a flow wrapping machine, which provides simple sealing for easy transportation and organization.

These advancements in packaging technology have greatly improved efficiency, food preservation, and convenience.

When you buy a packaging machine for the first time, you need to see if the factory has similar packaging cases, which can quickly identify its strength and experience.

In addition, we should pay attention to the specialization of the factory equipment and whether the machinery has the ability to innovate, which can flexibly change the packaging solution.