A good packaging equipment is inseparable from daily maintenance and proper repair. You may think that if the machine malfunctions, you can directly find a maintenance company to deal with the door, but sometimes some small problems can be solved immediately by understanding the horizontal bagging machine, which is not necessarily not an easy thing. Today, we are going to explain to you the top 10 daily maintenance and requirements of horizontal bagging machine.

1.Premade bag thickness requirements .

General selection to the premade pouch packaging machine, the choice of premade pouch thickness can not be too soft, if the bag thickness is not enough, the seal will appear when the folding white edges, affecting the aesthetics.

Solution: the thickness of your packing bag to do thicker, for the shaped bag (bottle bag,like the photo), it can not make in 5-6 silk, this small shaped bag daily will be used to pack the now very popular ginseng concentrate, oral fluid and other functional beverages, in which our one output of a series for premade pouch packing machine of one-time can be packaged in 1-4 packages, greatly improving the production efficiency.

2.The sealing place appears not firm.

Check the sealing roller of the packaging equipment, the long working time will lead to glue residue on it, because there is a PE layer on the top of the bag, and the machine is to bond the bag by heating the PE layer.

Solution: Clean the sealing roller with a wire brush.

3.New packaging machine, avoid 24 hours time work.

After you buy the premade pouch packaging machine , in the working hours of 8-10 hours will need to stop to repair and inspection, the new machine at the beginning to avoid prolonged work, if a long time to work, there may be parts on the discomfort, it is best to first stop, detailed inspection, to avoid problems in the back of the packaging process.

Maintenance guide for accessories

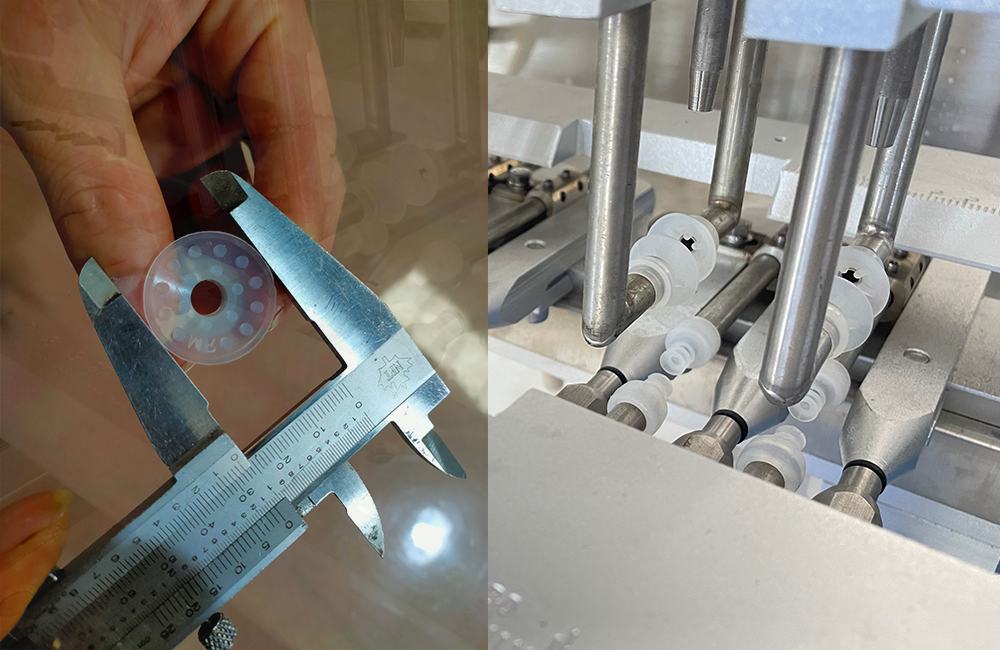

4.Suction cups

Suction cups, as an important accessory for bag packaging machine, need to be checked once a week.

Because the suction cup is relatively soft, long time use must oxidize, oxidation is easy to rot, if you continue to use the bad suction cup will lead to incomplete bag opening, directly affecting the material and sealing.

Solution: If the horizontal premade bag packaging machine in the daily work situation, three to days need to check once.

5.Heat pipe and thermocouple

Heat pipe and thermocouple, need to be regularly observed, whether the temperature is consistent, if the machine is packing granules and powder, generally will not burn out. On the contrary, in the case of packaging liquids, water may seep in or something, so it is easy to contact poor, resulting in burned out. This is general, is rarely bad.

Solution: If the heat pipe burns out, you have to change the heat pipe.

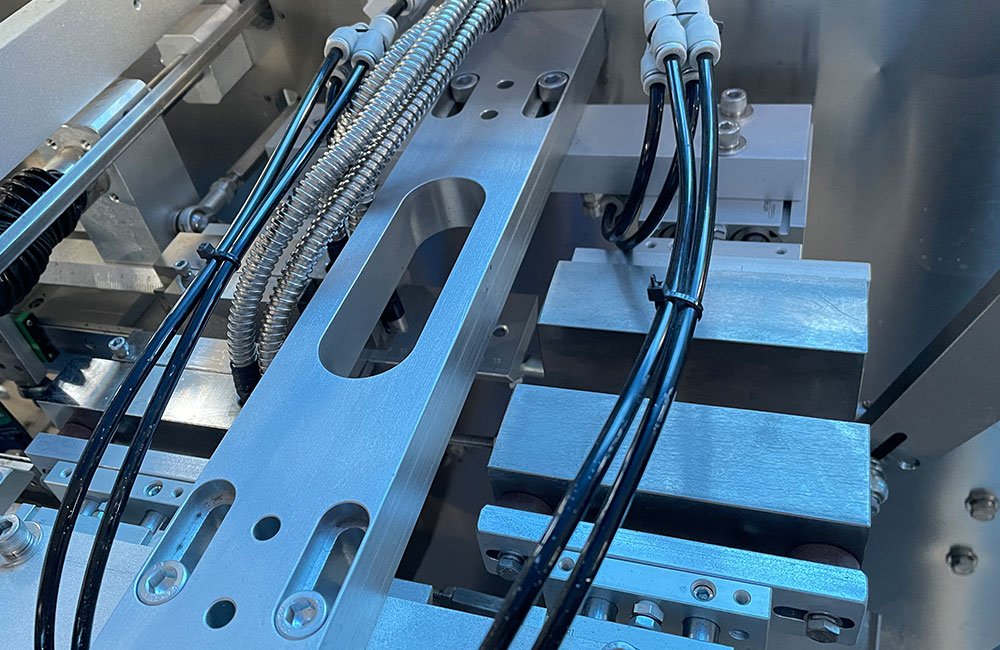

6. Bearings

Bearings in the encounter when there is sound and reminders, that is to remind you need to refuel, because the normal working condition is no sound. Do regular inspection habits, daily maintenance, check once a month. If you pack the product is liquid, you need to check once every two weeks.

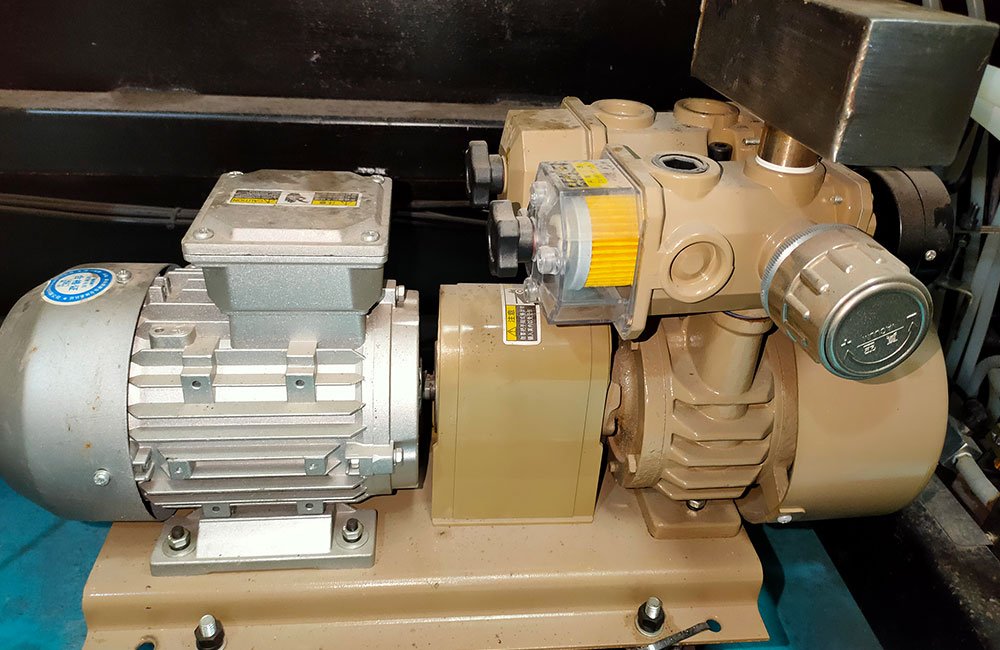

7.Vacuum pumps

Vacuum pump has insufficient suction

Solution: First of all, there is a button to adjust the suction power behind the machine, try to adjust the vacuum pump value, if the adjustment does not have much change, you need to check the filter inside the debris, clean up the filter impurities, keep the smooth state.

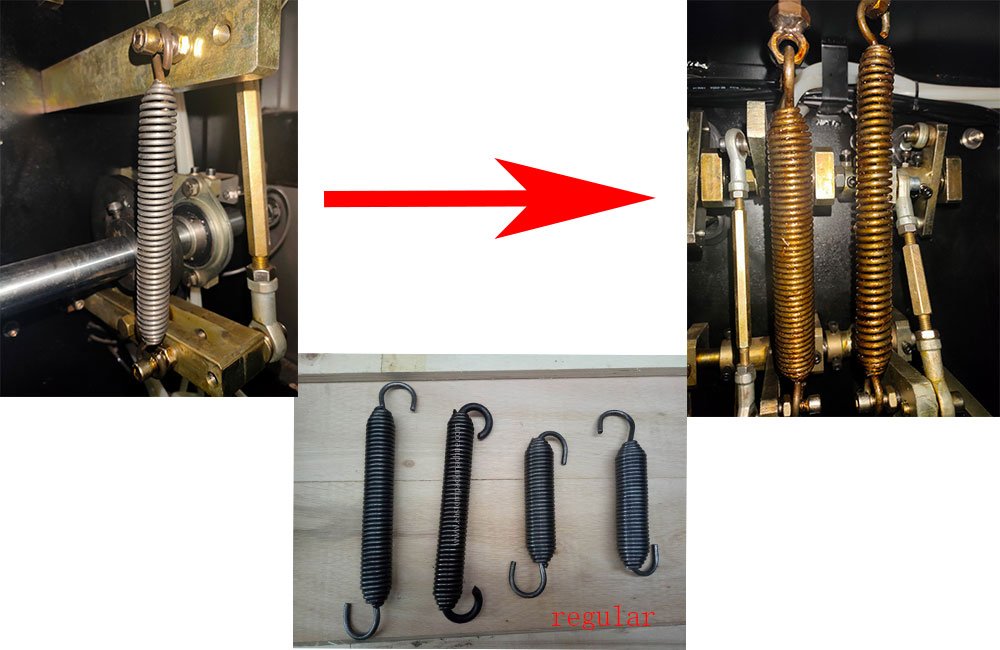

8. Tension springs

Tension spring rust will lead to crash

Solution: Tension spring needs to be checked once a week to observe whether there is no rust, if rust is found, the tension spring in the case of rust is very easy to break, so regular inspection of the tension spring, if rust should be replaced immediately, remember not to break off before replacing, so that affects the machine and equipment jamming, it will crash.

9.Air pressure control of the machine.

Air pressure must reach 0.6 (average 600-700) or so, start about 400-500, the air pressure should be uniform generally in 300, if less than 300 below will automatically alarm, so when the machine is working before you have to check whether the air pressure is stable before continuing to work.

In general, if you want to the premade bag packaging machine to work well for you, routine daily maintenance is necessary!