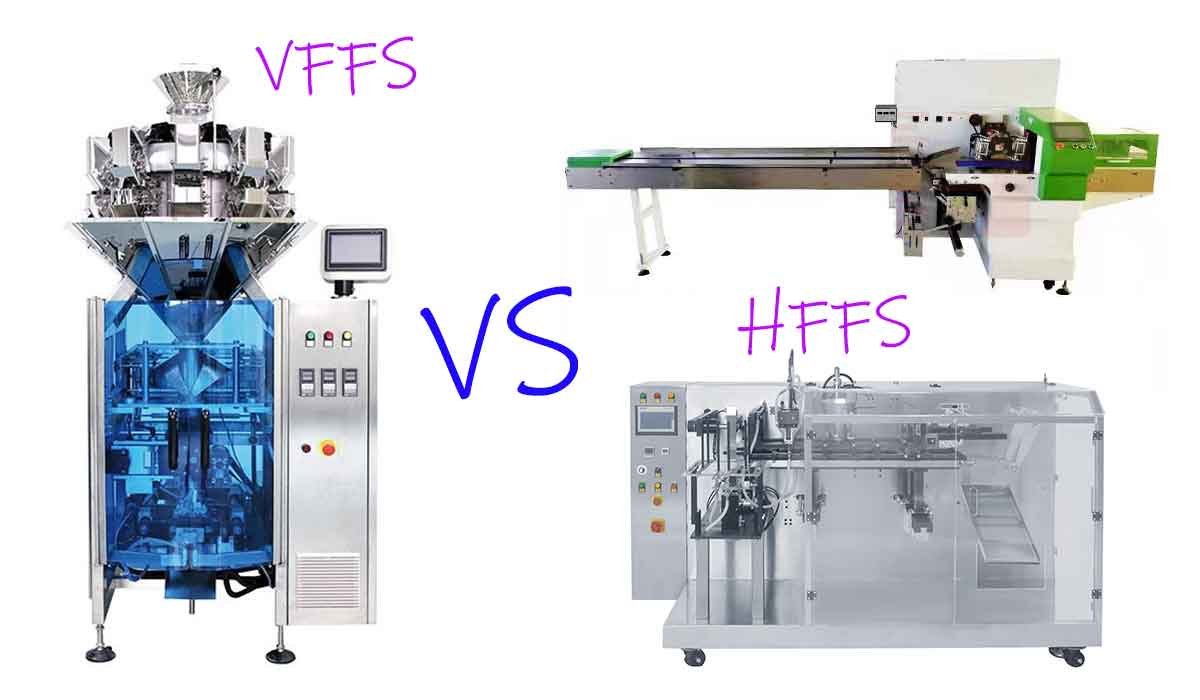

Both are packaging machines, but what’s the difference between a Vertical Form Fill Seal (VFFS) Machine and a Horizontal Form Fill Seal (HFFS) Machine? Which one will truly solve your packaging problems?

Today, we’ll clear up this confusion and help you find the right packaging machine to improve your production speed and reduce your labor costs. Whether you’re looking to buy a packaging machine or not, this article will help you make an informed decision.

Comparison of VFFS and HFFS

Vertical Form Fill Seal Machines (VFFS)

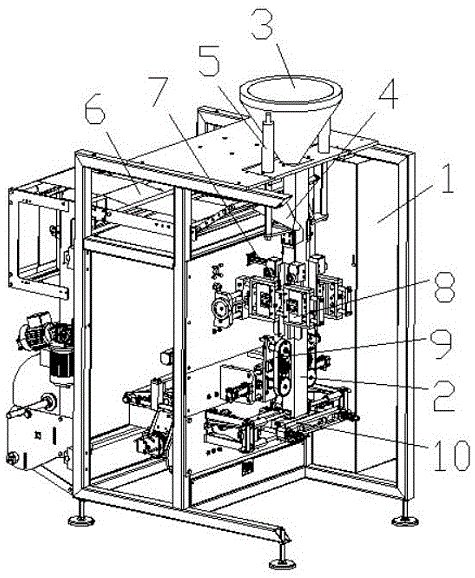

#Vertical Form Fill Seal Machines Working Principle

Today, let’s explore the daily role of the vertical packaging machine in a different way. The working principle of a vertical packaging machine can be summarized as Material Feeding → Film Forming → Automatic Bagging → Sealing and Cutting.

Imagine you have a vertical packaging machine working in front of you. It’s like a magician, transforming flat packaging film into perfectly shaped bags while automatically filling them with products.

First, the machine has a roll of packaging film, like a large roll of cling film. This film is gently pulled from the reel. Then, something magical happens. The film is guided through a series of rollers and molds by the machine, gradually turning into a 3D bag shape. The machine cleverly seals the bottom of the bag, making it ready to receive the product.

Next, if you have snacks or powders to be bagged, the machine will accurately control the product flow, allowing the products to fall into the already-formed bags. After filling, the machine won’t stop to rest. It will immediately seal the top of the bag with heat or adhesive, ensuring the contents are safe and hygienic.

The best part is that all of this is automatic and super fast. The machine can measure and cut on its own, ensuring each bag is of uniform size. It can also cut the packaging film at specific positions as needed to prepare for the next bag. If there are different product sizes or packaging requirements, you can easily set it up on the control panel, and the machine will flexibly adjust and continue working efficiently.

# VFFS Benefit

- High-Speed Automated Packaging: Increases productivity with high-speed packaging.

- Versatile Application: Suitable for granules, powders, and liquids.

- Space-Saving Design: Saves production space in your facility.

- Easy to Operate: Simple controls make it easy for employees to learn.

- Low Maintenance Costs: Reduces the cost of maintenance.

- Integrated Functions: Features like date printing and gas flushing improve packaging efficiency and quality.

- Full PLC Control: Enhances the automatic packaging process.

With these advantages, a vertical packaging machine can greatly improve your production efficiency and packaging quality.

Horizontal Form Fill Seal Machines (HFFS)

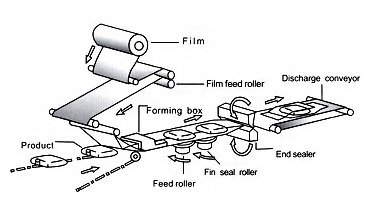

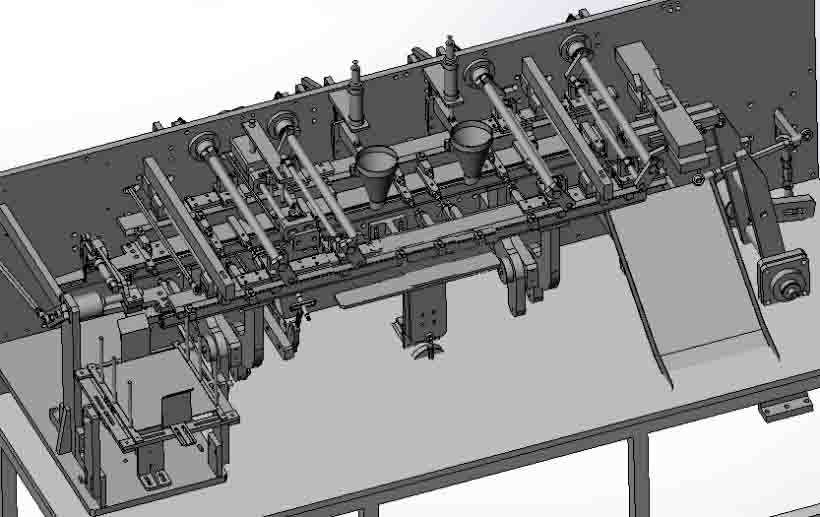

# Horizontal Form Fill Seal Machines Working Principle

For Horizontal Packaging Machines, you can think of their packaging direction as horizontal, while the principles are similar to those of Vertical Machines. Thus, the basic principle of horizontal packaging machines can be understood as Horizontal Film Feeding, Automatic Bag Forming, Filling, and Sealing.

Imagine you’re standing next to a horizontal packaging machine, watching it smoothly complete the packaging task. This machine operates like a production line, but all movements unfold elegantly in a horizontal direction.

At first, a large roll of flat packaging film slowly unwinds and passes through a series of delicate guiding devices. Then, like magic, the machine gradually transforms the flat film into the desired bag shape as it moves horizontally. Along the way, the bottom is seamlessly welded or glued to prepare for loading items.

As soon as the bag shape is formed, the machine’s “eyes”—Sensors—closely monitor whether there’s a product to be packaged. Once the product is in the right position, the sensor gently signals the filling system, and your product, whether food or small parts, is precisely placed into the newly formed bag.

Next, the machine wastes no time. It uses pneumatic or mechanical pressing devices to gently ensure the product is properly positioned, then seals the top with either heat sealing or adhesive, ensuring the contents are safe and fresh. Finally, the completed bag is cut and sent out from the end of the production line, while the new packaging film continues this cycle.

The whole process is smooth and seamless, and each step is fully automated. You only need to supervise from the side and enjoy the efficiency and convenience that automation brings.

# HFFS Benefit

- Adaptability to Various Materials: Suitable for different types of materials.

- Adjustable Bag Types: Offers flexibility in bag shapes.

- Efficient Packaging: High-speed packaging (single machine speeds range from 70 bags/minute up to 140 bags/minute), allowing you to meet your daily production needs efficiently.

- Servo-Controlled: Reduces failure rates and extends the machine’s service life.

- Low Maintenance Costs: Minimizes maintenance expenses.

- High Space Utilization: Ideal for packaging powders, sauces, and granules.

A Horizontal Packaging Machine can efficiently fulfill your needs by catering to different material requirements.

The Points in Common

You can understand their similarities from two perspectives. First is the packaging function, and second, both use roll film to form bags through the packaging machine. Here’s a more detailed explanation:

A. Function of Forming, Filling, and Sealing

Forming, Filling, and Sealing Functions: Whether it’s a horizontal or a vertical packaging machine, their basic workflow includes three key steps—forming, filling, and sealing.

B. Package Film in a Roll to Form the Pouch Shape

Rolling Film into Bags: Both types of packaging machines start with roll film as the packaging material. They use the film and, through the machine’s internal bag-making system, cut and shape it into bags for subsequent filling and sealing. This process shows their similarity in material usage, although the specific bag-forming methods (Vertical Bag-Making for vertical machines and Horizontal bag-making for horizontal machines) differ.

The Points in Difference

1. Operation Difference

You can see from the pictures that their operations are different. (Figure A is the VFFS, Figure B is the horizontal packaging machine)

Vertical Packaging Machine: Usually has a vertical structure with the roll film located above the machine. The film forms bags through a vertical bag maker and completes filling, sealing, and other processes. The operation interface is mostly controlled via a touchscreen, making it easy to adjust parameters and monitor the production process.

Horizontal Packaging Machine: Divided into pre-made bag type and form-fill-seal type. The Premade Bag Packing Machine type uses pre-formed bags and completes the packaging process through horizontal bag feeding, while the form-fill-seal type directly makes bags from roll film inside the machine. Horizontal machines may require more manual intervention, especially when replacing pre-made bags.

2. Adaptability to Various Materials: Suitable for different types of materials.

You might wonder, since both are packaging machines, shouldn’t they package the same products? But keep in mind that different industries have different packaging requirements, and the equipment they use also varies.

Vertical Packaging Machine:

Due to its flexibility and versatility, the vertical packaging machine is widely used in various industries, including food, pharmaceuticals, chemicals, and daily goods. It is suitable for packaging products in granular, powder, liquid, and solid forms.

Food Industry: Widely used for packaging snacks, cereals, coffee, tea, and other products, especially suitable for rapid, large-scale production.

Pharmaceutical Industry: Used for packaging medicines and health supplements, requiring precise measurement and a sterile environment.

Daily Goods: Ideal for packaging large-volume solid products like laundry powder and pet food. Many factories emphasize packaging efficiency and stability.

Special Considerations:

- Accuracy Control: Given the high speed of vertical packaging machines, it’s crucial to ensure packaging accuracy, especially in the measurement and filling stages.

- Adaptability Adjustment: Capable of quickly adjusting to meet packaging needs of different sizes and shapes, reducing changeover time.

- Automation Level: Make full use of automation features, such as computer-set bag length and touchscreen storage of packaging parameters, to minimize human error.

- Safety and Certification: Particularly in the pharmaceutical industry, equipment must comply with relevant GMP (Good Manufacturing Practice) standards to ensure safety in the production process.

Horizontal Packaging Machine:

Horizontal packaging machines are used in the food, pharmaceutical, chemical, and other industries. They are especially suitable for large-scale production requiring precise measurement and high-quality sealing, such as candy, snacks, and hardware parts.

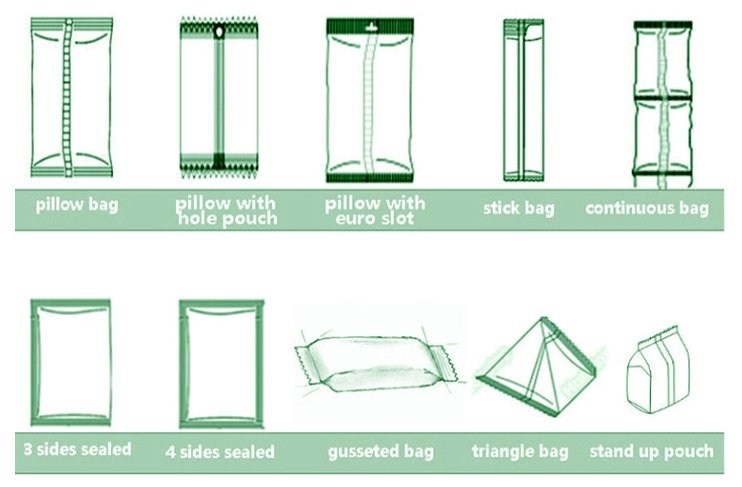

Food Industry: Suitable for packaging solid foods (e.g., chips, biscuits, candy, nuts), powdered foods (flour, starch, milk powder), and liquid or paste foods (juice, jam). Especially ideal for products requiring various packaging bag styles (e.g., 3-side seal, 4-side seal, stand-up pouches, zipper bags, and irregular-shaped bags).

Cosmetics Industry: Used for packaging solid or powder products, such as facial masks, foundation, and eyeshadow. Particularly suitable for products with high aesthetic requirements for packaging.

Chemical Industry: Suitable for packaging small-grain or powder-like chemicals, requiring special attention to moisture resistance and contamination prevention.

Special Considerations:

- Cleaning and Hygiene: Especially in the food and cosmetics industries, regular cleaning and disinfection are essential to ensure compliance with industry hygiene standards.

- Choice of Packaging Materials: Choose suitable packaging materials based on product characteristics, such as moisture resistance, light protection, breathability, or anti-oxidation.

- Sealing Performance: For liquid or paste products, ensure good sealing performance to prevent leakage.

- Compatibility: Choose a filling system compatible with different product forms (e.g., granules, powders, liquids).

3. Packing Speed

When comparing different models of packaging machines, you’ll find that their packaging speed varies depending on the specific model, design, and configuration. Generally speaking, Vertical Packaging Machines tend to achieve higher efficiency because of their compact design and smooth, continuous workflow. They can complete more packaging tasks in a given time frame. This is especially evident in high-performance, high-speed Vertical Packaging Machine models.

4. Only the HFFS Pack can Stand Up Pouch

You might also consider this question, but in reality, whether you choose a vertical or horizontal packaging machine, you should know that both have models specifically designed for producing stand-up pouches. Vertical packaging machines, with specially designed forming devices, can fully handle making stand-up pouches. On the other hand, horizontal packaging machines using HFFS technology also excel at making stand-up and upright pouches because they can more precisely control the bag shape and ensure a strong seal at the bottom in the horizontal direction. So, don’t let preconceived notions mislead you; the key is to choose the right machine based on your specific needs.

5. Packing Bag Difference

When using a vertical packaging machine, it can create vertically standing bags, which are particularly suitable for products that need to be displayed hanging up or placed directly on shelves. For traditional horizontal packaging machines, also known as pillow packaging machines, the bags produced usually lie flat like small pillows (pillow bags). However, if you choose a new horizontal premade bag pouch packing machine, it’s a different story. This machine is designed to create stand-up pouches specifically built for stable stacking and storage, making them ideal for product packaging that requires efficient use of storage space.

6. Factories with Different Production Capacities.

You will choose the type of packaging machine that best suits your needs based on your factory’s product characteristics and production scale. If you run a small factory or focus on specialty product production, you may prefer to use a vertical packaging machine because it provides flexibility and takes up less space, making it well-suited to your production environment and capacity requirements.

On the other hand, if your factory operates on a large scale or faces production challenges requiring high-speed and high-volume packaging, horizontal packaging machines will be your reliable helper, especially premade bag horizontal packaging machines. These machines can help your production line achieve a high degree of automation, ensure production efficiency, and meet the demands of large-scale continuous operation.

7. Application

When you’re facing packaging needs that require a lot of customization, have limited space, or frequently change product types, a vertical packaging machine will be your reliable assistant, as it can better handle these diverse challenges.

However, if your production scenario focuses on large-scale, standardized operations and has strict standards for uniform bag specifications and sealing quality, then horizontal packaging machines will excel. They are more common and crucial in such high-efficiency production lines.

8. Different Types of bags for them

When choosing packaging machines, you’ll find that each has its strengths and can seal various types of bags. With a Vertical Packaging Machine, you can flexibly create simple 3-side and 4-side sealed bags, classic back-sealed bags, gusseted stand-up bags that enhance product display, and crimped stand-up bags that elevate packaging quality.

This type of machine can usually package chocolate chip cookies, sambos chips, coffee bean pin bags, fudge, cheese-flavored potato chips, nuts, candies, etc.

As for Traditional Horizontal Packaging Machines, they excel at making back-sealed bags (Pillow bags) and chain bags to meet basic packaging needs.

This type of machine can usually package Bread, cake, small-size snacks, sanitary napkin, instant noodles, tissue paper, spoons, napkin paper, chocolate bars, etc.

However, if you switch to a new Horizontal Premade Bag Packaging Machine, the choices become even more diverse. This advanced equipment can not only produce 3 side seal pouches, 4 side seal pouches, and pillow bags, but also handle gusseted bags, stand-up pouches, and zippered bags with convenient opening and closing features. It can even create combined stand-up and zipper bag types. Moreover, it supports side-gusseted bags, 8-side-sealed bags, 8-side zipper bags, as well as shaped bags and angled spout stand-up bags, greatly expanding the possibilities of packaging design and turning every packaging opportunity into a showcase of product features.

This type of machine can usually package beef jerky snack packs, honduras chips,zambos chips, chili lime plantain chips, coffee beans in zipper bags, nuts, honduran candy, dried fruits, etc.

Tips for Choose The Right One for You!

Mastering the following five points will quickly help you determine whether a vertical machine is right for you, or if a horizontal premade bag machine can better solve your current problems.

Step 1: What kind of Product Do you Need to Pack?

First, you need to understand the characteristics of your product. Different products require different weighing devices, which fall into three main categories: liquid, solid, and powder. Typically, vertical packaging machines pack one bag at a time, while horizontal packaging machines can pack 1 to 4 bags at a time.

Step 2: What kind of Bags Types Does Your Packing Bag?

Secondly, you need to know the type of bag your product will be packaged in. Vertical machines can form bags in one piece, with bag types including 3-side seal bags, 4-side seal bags, back seal, gusseted stand-up bags, and crimped stand-up bags.

Traditional horizontal packaging machines have a pillow-like appearance, hence they’re also called pillow packaging machines. These machines only form two types of bags: back-seal bags and chain bags. They are limited but high-speed.

With continuous innovation, another type of horizontal packaging machine has also become useful. This machine doesn’t form bags but primarily uses pre-made bags (the bags are already made, and the horizontal premade bag machine handles filling and sealing). It can package 3-side seal, 4-side seal, back seal, gusseted bags, stand-up pouches, zippered bags, stand-up zipper bags, back-seal bags, side-gusseted bags, 8-side-seal bags, 8-side zipper bags, shaped bags, and angled spout stand-up bags.

Clearly, compared to vertical machines, traditional horizontal packaging machines have limited bag types. New horizontal packaging machines are compatible with a wider range of pre-made bag types, handling bag feeding, filling, and sealing. While vertical machines don’t support as many bag types as horizontal premade bag machines, they can automatically complete bag forming, filling, sealing, and cutting with one machine. So, if you don’t have specific requirements for your product’s bag type initially, a vertical machine can also be a good choice.

Step 3: Equipment Capacity Requirements (Packaging Speed)

However, your packaging speed requirements matter. You need to know the weight per package you want and your daily production output. These two factors directly affect the type of machine you need. Smaller packaging weights will naturally result in faster speeds, but if you need to package over 1 kilogram, the type and model of the machine will differ, and the speed will accordingly be a bit slower.

Step 4:Additional Feature Options Required

Secondly, if you want to add any features to the machine, you need to discuss this with the packing machine manufacturers when consulting about the machine. For example, if your packaging product is bread and you need to extend its shelf life, you might ask what percentage of nitrogen gas is added. We would then provide you with a solution that includes a vacuum pump and a nitrogen pump. The reason is that removing part of the air and then adding nitrogen can effectively extend the bread’s shelf life to six months.

General optional features for machinery include: adding a standard ribbon coder, metal stamping coder (stamped at the top seal of the bag), a zipper opening device (for packaging premade bags), vacuuming, nitrogen gas filling, secondary sealing (used for cooling nylon bags to ensure a stronger seal), bag tamping device, dragging device for bags over 1kg, punching, adding a dust removal device, adding a bag arrangement conveyor (used for transporting stand-up bags with side spouts), adding servo motors (needed for multi-head scales or turntables requiring three drops), and using Siemens motor controls.

Step 5:Machine Footprint

Finally, when purchasing a machine, you need to understand whether your production space can accommodate it and leave room for production. If your production workshop is small and doesn’t have much space, you can consider buying a vertical machine because it takes up less floor space than horizontal packaging machines.

However, if your factory has a large area and you need to increase production capacity and expand your business, the horizontal machine is also a good choice for your reference.

Conclusion

After reading this article, here’s a summary: Vertical Packaging Machines and Horizontal Packaging Machines are the two main forces in modern packaging.

Vertical packaging machines, through vertical filling and sealing, are suitable for solid and granular products. They are space-saving and highly efficient. Horizontal packaging machines excel at handling liquids, powders, or irregularly shaped items. Using horizontal stacking and sealing, they offer broad adaptability and strong packaging stability.

Each has its advantages, providing efficient and flexible packaging solutions based on different material characteristics and production needs, jointly advancing automation in the packaging industry.

If you are still determining which is suitable for your product, contact our expert! We also provide other types of packaging machines, please click here to view them.

More Resources

How to use the Flow Wrap Machine –From SembsunPack

What is the Electronic Combination Scales –From SembsunPack

What is the Poly Bag –From SembsunPack

Application of Powder Filling Machine –From SembsunPack

Types of Flexible Pouches –From SembsunPack