What is The Process of the Powder Filling and Sealing Machines

Types of the Automatic Powder Filling and Sealing Machine

Do you know what types of automatic powder filling machine are available in the market? We commonly have: vertical machine, to the bag machine, filling machine, they with the screw rod powder head can be fully automatic packaging powder, the common powder detergent powder, dry chemical powder, washing powder, fine powder, milk powder, pharmaceutical Common powders are detergent powder, dry chemical powder, washing powder, fine powder, milk powder, pharmaceutical powder, protein powder, spice powder, toner powder, chemical powder, coffee powder, cosmetic powder, face powder, talcum powder and others. The automated program can complete the work of packaging efficiently and is one of the essential tools for modern manufacturers of packaging.

Here’s an overview of how different packaging machines package powders.

1.Pouch Loading

Vertical machine: You can easily see that the vertical packaging machine model is an all-in-one machine for bag making, discharging and sealing, at the same time when the bag is generated is when the powder enters the bag.

Bag Feeder: This model is specially designed for pre-made bags, you just need to put the bag inside the bag slot, the machine will grab the bag.

Filling machine: Powder can filling machine general filling is the bottle packaging.

2. Pouch Gripping

Automatic powder filling and sealing machine in the horizontal bagging machine used in the bag type common stand up pouch , zipper pouch and doypack, these 3 stand up pouches have a good sealing and reopening and sealing function, most of the manufacturers who want to bag one of the choices.

In the horizontal bag packaging machine and rotary bag packaging machine you will see a mechanical arm is to grab the bag placed inside the bag chute, transferred to the packaging track, generally this step we called grab bag.

3. Optional Printing

Some manufacturers will require their packaging is the need to type the date or other information, horizontal to the bag packaging machine in the machine to grab the bag is completed, there will be a device is to type you say you need the code or information. We call it a coder, if manufacturers need to type the date of each day, the order will be equipped with a set of numbers, manufacturers need to change the numbers and letters every day, the buyer according to the production schedule to adjust their parameters, so easy to operate.

4. Opening & Detection

With the code, the bag is originally out of the closed state, is not conducive to powder filling, so before loading, the packaging machine has a step is to open the bag, this step you may feel optional, but in your prefabricated bag type, prefabricated bag material is relatively soft, will be folded in the packaging process or because it is not completely open resulting in powder overflow, which will affect the finished product’s Aesthetics, and secondly, the workshop dust is also relatively large, so this one step to open the bag is indispensable.

Some bags have a zipper, and the machine is used to open the bag to a pneumatic principle, so when the packaging is with a zipper bag, you need more force to open the bag, this can be verified with the production of packaging machines manufacturers, it is best to give you the bag to the manufacturers of test machines, which will ensure that the machine to your packaging plant can be quickly put into production.

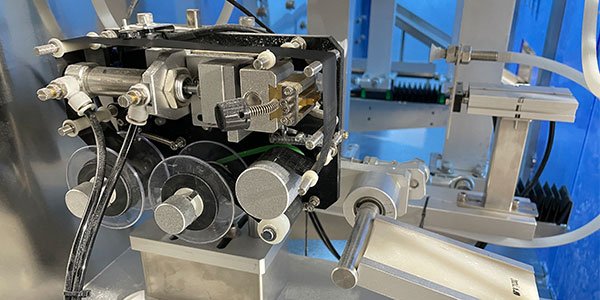

5. Powder Filler filling

When the prefabricated bag type is completely opened, the conveyor bar will transfer the bag to the down-feeding port, according to your demand for customized single down-feeding port number to be discharged. There are single-discharging, double-discharging, triple discharging and quadruple-discharging available in the market, these are designed to match the product you need, usually we call these single multiple discharging packaging models as one out of multiple prefabricated bag packaging machines. The powder is fed from the auger filling directly to the bottom of the bag.

6. Pouch Sealing

After the product is finished feeding, the next step is sealing. A sealing machine is a heating element, common hot knife, heat sealing strip, or high frequency induction head. Manufacturers generally pre-heated to a set temperature, contact with both sides of the bag material, through the pressure and heat to make the prefabricated bag film melt to form a seal.

7. Seal Cooling

Cooling: To enhance the strength and tightness of the closure, the freshly heat-sealed pouch is rapidly cooled down by a cooling system, which helps the plastic material to re-cure and fix the closure shape, preventing it from reopening due to subsequent temperature changes.

8. Other options Choose

Because powder particles are relatively small and light, it is inevitable that they will float in the air during the packaging process. In order to minimize the amount of powder in the air, we recommend that customers who purchase a powder filling machine generally add a dust collection device in order to collect the powder that floats due to the packaging process, which has the advantage of collecting and removing the dust generated not only during the packaging process but also to maintain the quality of the product. This benefit is not only to collect and remove the dust generated during the packaging process but also to maintain the safety and hygiene of the packaging area and reduce the loss of powder materials.

Secondly, you can also increase the finishing bags of workstations, when the powder has been packaged in the bag inside, in order to seal the bag after the aesthetics of the bag heat, add a finishing blowing equipment, will make the bag mouth heat sealing up good-looking. There is the pursuit of fine manufacturers will require the addition of a finishing bagging station.

You can add a finished product conveyor belt, when the product is finished heat sealing, the next step is to organize the product, in order to save labor, add a finished product conveyor belt, on the one hand, it can be automatically organized and transported to the corresponding position, on the one hand, it can efficiently improve the speed.

Secondly, the metal detector can detect whether the powder that has been packed is purely in foreign matter or metal products, which ensures the safety of the products.

Automatic powder filling and packing machine is a packing machine with automatic weighing device, suitable for milk powder, pharmaceutical powder, protein powder, spice powder, toner powder and so on. Powder products, its workflow as mentioned above, if your packaging products are powder, you also don’t know what packaging machine to look for packaging, you can look at our protein powder filling machine.