Horizontal Premade Pouch Packing Machine packs the beef jerky

Know more about the Horizontal Premade Pouch Machine.

Evolution of Packaging Machines

You might wonder why most online resources discuss vertical form fill seal machines and flow wrapping machines, but there is less information on horizontal premade pouch packing machines. The reason is simple: this type of packaging machine is a recent invention. It incorporates modern technology and innovation, making it a popular and widely used choice.

Development of Horizontal Premade Pouch Packing Machines

In recent years, horizontal premade pouch packing machines have developed rapidly in the packaging machinery industry. Manufacturers continuously innovate and integrate new technologies. Our new mini model has received positive market feedback, indicating a bright future for horizontal premade pouch packing machines in the industry.

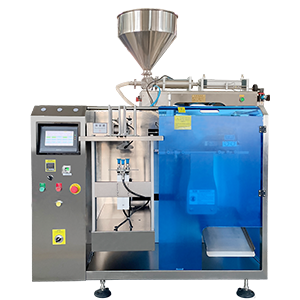

Mini Type Premade Pouch Packing Machine

As an automatic pouch packing machine, do you know how the premade pouch packing machine packages products? What types of bags is it suitable for? Today, we’ll explain the jerky packing machine, which is the most common customer case in our factory, and how it works.

What is the Horizontal Premade Pouch Packing Machine?

From the literal meaning, you may understand “premade pouch” as a pre-manufactured bag. This machine is a horizontal pouch packing machine, meaning that the bags it uses are already made and do not need the machine to create them before packing the product. This is ideal for customers who have specific requirements for their packaging bags, as they can have the pre-designed bags produced in advance.

Unlike vertical packaging machines, this machine completes the main steps of opening the bag, filling it, and sealing it without the need to form the bag itself. Additionally, this machine can perform multiple filling processes.

Types of the Horizontal Premade Pouch Packing Machine

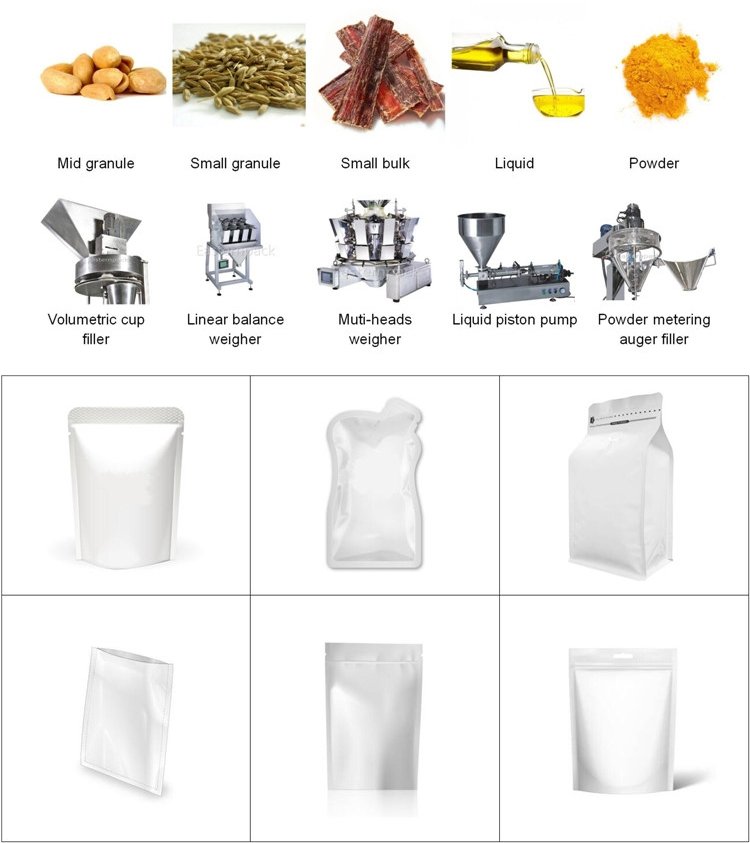

Categorized by Product Type

You can easily categorize products into three main types: granules, powders, and liquids. The first step in choosing the right packing machine is to select the appropriate filling device for your specific product.

Granular Products: If you need to pack granular products, start by informing the manufacturer about the size of the granules. It’s best to send samples to the manufacturer for accurate assessment. Once the size is known, the manufacturer will need to know the dimensions of your packaging bags (length and width) to design the bag placement, opening, and sealing mechanisms. Also, specify the weight of each package and whether additional devices are needed to manage the weight during the packing process. Common granular products include jerky, dried fruits, nuts, peanuts, toys, tea, candies, frozen foods, chocolate, coffee beans, pasta, etc.

Powder Products: For powder products, inform the manufacturer about the desired accuracy and the flowability of the powder. Also, provide the packaging weight. Common powder products include milk tea powder, coffee powder, spices, chocolate powder, flour, lotus root powder, baking soda, chili powder, milk powder, protein powder, etc.

Liquid Products: When packing liquid products, consider the viscosity, as it affects the filling speed. Check if the liquid contains granules and whether stirring or heating is required. The best approach is to describe your product clearly so the manufacturer can simulate and test the packaging process. Common liquid products include laundry detergent, juice, disinfectant, etc.

Granule-Liquid Mixtures: Using multiple filling devices for granules and liquids. For example, if you want to pack face masks with both a mask sheet and essence, the machine will be designed with separate filling devices for the granules and liquids, allowing for orderly operation.

Advanced Horizontal Pouch Packing Machines

We have also developed a series of advanced horizontal form fill seal machines capable of packing multiple bags at once. These include machines that can simultaneously pack two, three, or four bags. They are especially popular for liquid products, such as new types of small pouch drinks, significantly improving production efficiency. If your product is small-pouch packaging, feel free to contact us to discuss these new multi-bag horizontal pouch packing machines.

D-85S Twin Output Premade Pouch Packing Machine

Applications and Industries

The horizontal pouch packing machine is widely used in both food and non-food industries.

Food Industry: In daily life, you can see these machines used for packaging snacks, dry fruits, sauces, spices, chips, and more. If you want to find the specific packing machine for your product, simply add the product name before “packing machine” in your search. For example snack packing machine, chips packing machine, dry fruits packing machine, sauces packing machine, spices packing machine, potato chips packing machine, etc.

Non-Food Industry: In the non-food sector, the horizontal pouch packing machine is also widely used.

Pharmaceutical Industry: For instance, the machine is used for packaging pills and other medicines. For example: Medicine packing machine.

Cosmetic Industry: For cosmetics, it can pack creams, lotions, and samples.For example: Creams packing machine,lotions packing machine, sample packing machine.

Hardware and Electronics: In hardware and electronics, it is used for small parts, cables, toys, and chemicals.For example Small parts packing machine, cables packing machine, toys packing machine,chemicals packing machine

Structure and Components

When you purchase a horizontal pouch packing machine, it’s important to understand the function of its different stations and the additional features that can be integrated. Generally, the horizontal pouch packing machine has three main stations: pouch opening, filling, and sealing. Additional components include feeding and weighing systems.

Main Body and Frame:

Made of durable 304 stainless steel, providing strong support for daily packaging needs.

Feeding System:

The hopper and conveyor are selected based on the type of product. The feeding system for powders, granules, and liquids includes: Auger fillers, Volumetric fillers, Liquid fillers

For more information on feeding equipment, click on “Packaging Equipment” to quickly identify the right system for your needs.

Pouch Opening System:

Opens your pre-made pouches for filling. This system is adjusted based on the type of pouch. For instance, if your pouch has a zipper, the suction cups’ strength is increased to open the pouch properly for filling.

Suction Cups and Mechanical Arms:

These components play a crucial role in transferring the pouches and conveying them post-filling.

Filling System:

Fill the pouches with the product after weighing. You can adjust the filling system according to your weight requirements. If you need to remove air, a vacuum device can be added. To reduce oxidation, a nitrogen filling device can also be integrated at this stage.

Sealing System:

Once the product is filled, it moves to the sealing system, primarily using heat sealing. For special films, we can modify the system based on customer requirements.

Heat Sealing Bars and Pressure Mechanisms: After filling, certain pouch types may need an additional step to arrange the seal area neatly before sealing, ensuring the finished product looks aesthetically pleasing.

Coding and Labeling System:

Usually completed before filling since the pouch opening system has ample space to accommodate a coder.

Control Panel and User Interface:

You can choose from our partner brands like Siemens, or opt for cost-effective alternatives based on customer feedback. The user interface supports multiple languages, allowing customers worldwide to learn quickly.

By understanding these components and their functions, you can ensure that you choose the right configuration for your packaging needs.

Cost of Pouch Packing Machine

You can compare the costs: for the same configuration, the horizontal pouch packing machine is cheaper than the rotary pouch packing machine. This is because the compact design of the rotary pouch packing machine makes it more expensive to produce. For more information on rotary pouch packing machines, you can check out our previous article “Difference Between Rotary Packing Machine and Horizontal Premade Pouch Packing Machine.”

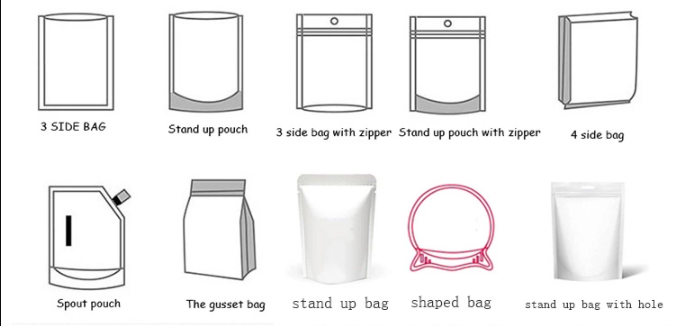

Types of Pouches

Here are some common types of pre-made pouches you can find in the market:

- Three-side seal pouches

- Stand-up pouches

- Four-side seal pouches

- Zipper pouches

- Spout pouches

- Special-shaped pouches

Types of Materials Used for Pouches

- PE (Polyethylene)

- PET (Polyethylene Terephthalate)

- Foil

Material Thickness and Quality Considerations

When choosing pouch materials, consider the thickness and quality to ensure they meet your packaging needs.

Premade Pouch Types

The Benefit of the Horizontal Premade Pouch Packing Machine to Pack Beef Jerky

Why Choose the Horizontal Premade Pouch Packing Machine to Pack Beef Jerky

Why should we choose premade pouches to pack beef jerky? There are various packaging options for beef jerky on the market, such as stand-up pouches, individual vacuum packs, zipper stand-up pouches, shaped pouches, back-seal bags, and more attractive pouch types. These pouches fall within the packaging range of the horizontal premade pouch packing machine. The machine’s pouch placement stations are adjustable, allowing you to change pouch sizes within a certain range. However, it’s essential to consult with the factory first.

Since beef jerky is a snack food, customers often recommend adding desiccants or antioxidants. This step requires a secondary filling, which is a significant advantage of the horizontal premade pouch packing machine as it can handle multiple fillings.

If you choose to use zipper pouches, the machine includes a pouch opening device that can be adjusted pneumatically to meet the requirements of opening the zipper, offering versatility in pouch types.

What Does a Complete Beef Jerky Packaging Line Look Like? (Video)

Technical Specifications

- Packaging Speed: 55-70 pouches per minute

- Machine Weight: Over 600 kg to ensure stability during the packaging process

- For detailed power consumption and air pressure requirements, please refer to our horizontal premade pouch packing machine’s detailed page.

Maintenance Requirements

Under normal usage, the machine should be cleaned at least once a month. Regular cleaning ensures product hygiene and extends the machine’s lifespan.

Operation

We provide detailed installation manuals and instructional videos to help you quickly understand and operate the machine.

Common Troubleshooting Tips

Machine Jam: If the machine suddenly gets stuck during operation, first clear any foreign objects from the working stations and then restart the machine.

Safety Features

Our packaging machines are equipped with emergency stop buttons. In case of unexpected situations, the machine can be stopped immediately to reduce the risk of accidents and improve safety.

Conclusion

Summary of Key Points

This article covered the historical background, types, advantages, safety design, intelligent switches, servo control, machine specifications, pricing, and application industries of the horizontal premade pouch packing machine. These features highlight why this machine has become so popular in the packaging industry. Its stability and multifunctional capabilities make it a favorite among manufacturers.

FAQ

What are the packaging requirements for beef jerky?

- Safe packaging environment with minimal airborne particles and reduced human contact.

What is the best way to package beef jerky?

- Vacuum packaging.

Beef Jerky Packaging Bags/Pouches

- Stand-up pouches, vacuum packaging, stand-up pouches with zippers. Individual packaging includes three side seal bags and four side seal bags.

How long will homemade beef jerky last if vacuum sealed?

- Homemade beef jerky, when packed manually, is exposed to potential contamination and can’t completely eliminate air, accelerating spoilage. Manually packed beef jerky typically lasts 1-2 months, while machine-packed beef jerky can last up to 6 months.

How should raw beef be stored and which packaging machine is best?

- Common machines for packing raw beef are skin packaging machines and vacuum packaging machines, as they effectively remove air from the packaging, preventing bacterial growth and oxidation.

Other Premade Bag Packing Machines

Spout Pouch Filling Machine: We recommend using a pouch packing machine.

Multi-station Horizontal Irregular Pouch Packing Machines: These machines can pack two or more pouches simultaneously, significantly improving production efficiency and output.