In 2025, the packaging industry will be driven by automation, sustainability, precision, and speed. With rising costs and stricter ESG demands, bread producers face mounting pressure to modernize.

Twist tie tying packing machine models are emerging as a game-changing solution. As adoption grows, the twist tie machine market is projected to hit $800 million by 2032. Read on to discover how this smart tool is reshaping packaging.

Understanding the Twist Tie Tying Machine: A Quick Overview

At its core, a twist tie tying packing machine is an automated device designed to fasten twist ties around flexible packaging or items with speed and consistency. Its typical uses extend across bread bags, produce packaging, wire harnesses, cables, confectionery packs, and even medical kits.

Key Components Include:

Motorised Tying Mechanism: Handles the twisting and sealing with consistent tension.

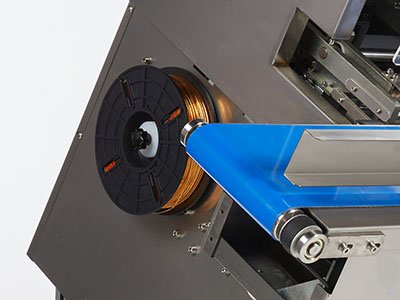

Wire Feeding System: Feeds pre-cut or spool wire ties into the system.

Digital Control Interface: Offers programmable settings for speed, tension, and product configurations.

Optional Conveyor Integration: Facilitates continuous, inline packaging flow.

Variants of These Machines:

Small Units: Ideal for small-scale or batch operations.

Such as the SXQX-300 fully automatic oblique tie tying machine and the DL-300 fully automatic vertical tie tying machine, the machine weighs only 100 to 130kg and is only a little over one meter long. It occupies a small area and is high-speed. The height of the conveyor belt can be adjusted. Depending on the size of the product, the average speed can tie 30-40 packages per minute.

High-Speed Inline Models: Designed for continuous, industrial production lines.Like the DQ-300 fully automatic tying machine, you can connect the belt to the production line, or customize the function according to your requirements.

Twist tie tying packing machines are no longer one-size-fits-all. Today’s models can handle diverse materials and operational scales, making them a flexible investment.

Why Bread Producers (and Others) Are Making the Switch

Twist tie tying packing machines directly address several longstanding challenges in modern packaging environments. Here’s how they bring value across the board:

1. Reducing Labour Dependency

Manual twist tying is repetitive and physically taxing. By automating this, you instantly free your staff of menial, error-prone jobs and let them concentrate on higher-value work. It’s a pretty good answer to growing labour shortages.

2. Achieving Consistent Packaging Quality

Hand-tied closures vary in tension and appearance. Automated equipment ensures a consistent tensile measurement on each twist tie. This allows you to enhance product integrity and shelf appeal.

3. Eliminating Common Production Bottlenecks

Manual tying can slow down end-to-end throughput on high-speed manufacturing lines. You can retrieve this bottleneck by using automated twist tie systems, contributing to a consistent and reliable packaging flow.

4. Improving Worker Safety and Ergonomics

By reducing awkward movements, they help avoid or eliminate RSIs (Repetitive Strain Injuries). Less manual handling means you get a safer working environment.

5. Supporting Compliance and Hygiene Goals

With tightening hygiene and traceability regulations — particularly in the food and pharmaceutical sectors — twist tie tying packing machines help meet 2025’s higher standards. They reduce direct human contact, offer better control, and integrate well with digital tracking systems.

Transforming Packaging in 2025: Key Advantages of Twist Tie Tying Machines

If you aim for greater speed, consistency, and environmental responsibility, twist tie tying machines can make your packaging lines more efficient. Here’s how they’re driving a new standard:

1. Driving Faster Throughput and Smoother Workflow

Modern systems are built for pace and can help you achieve tying speeds of 30 to 60 bags per minute, depending on the configuration.

Fully automated operation when linked with conveyors, sensors, and vision systems

Reduced downtime between shifts and fewer disruptions during high-volume runs

Increased consistency, even during extended production cycles

2. Ensuring Accuracy and Packaging Uniformity

Presentation and sealing quality are non-negotiable — especially for retail and regulated sectors.

Programmable tension control delivers precise, repeatable tying every time

Vital for maintaining freshness in bread, produce, and pharma kits

Supports retail-ready packaging with clean, consistent finishes

3. Reducing Energy Use and Supporting Sustainability

If you are focused on sustainability, these tools can help in the following ways:

Low power draw and optimised wire usage outperform traditional sealers

Cuts down on waste from errors or material overuse

Compatible with biodegradable twist ties, aligning with green mandates for 2025

4. Powering Smart Factory Integration

You will now find advanced twist tie machines designed for the Industry 4.0 landscape.

IoT-enabled systems allow remote diagnostics, real-time performance tracking, and preventative maintenance

Seamless integration with ERP and MES platforms for full production visibility

Select models feature AI-based jam detection and auto-correction, reducing human intervention

5. Suited to a Range of Sectors and Applications

Though essential in bakery production, you can now use these machines across multiple industries:

Food packaging: Hygienic, appealing sealing of bread, fruit, veg, and confectionery

Electrical and industrial: Efficient cable bundling and component tying

Medical and pharmaceutical: Sterile, tamper-evident closures for sensitive items

E-commerce: Fast, clean bundling of accessories and promotional materials in fulfilment centres

Technological Leaps Powering the 2025 Packaging Shift

The evolution of twist tie tying packing machines is not just mechanical — it’s deeply rooted in technological innovation. From smarter controls to eco-compatible materials, here’s what’s propelling their widespread adoption in 2025:

Smarter Interfaces and Control Systems

Modern twist tie tying packing machines are equipped with intuitive touchscreen HMIs (Human-Machine Interfaces) to help you:

- Save and recall product-specific recipes, ensuring rapid changeovers.

- Adjust speed, wire feed, and tie tension with precision to suit different packaging formats.

Eco-Friendly Material Compatibility

Environmental concerns are front and centre — and the machines are ready.

Designed to work with paper-coated and biodegradable twist ties, significantly cutting down on plastic use.

Fully aligned with international sustainability regulations and green packaging standards.

Flexible, Modular Architecture

Adaptability is key in 2025’s dynamic packaging environments.

Modular builds allow for easy upgrades or reconfiguration based on changing product needs.

Compatible with robotic arms and pick-and-place systems, supporting scalable automation without major infrastructure changes.

Improved Safety and Hygiene Standards

Machines are now built with sanitation and safety as core features.

IP65+ ratings ensure safe operation in wash-down or wet environments.

Fully compliant with GMP and HACCP, which are essential for sectors like food and pharma.

Procurement Insights: Cost Savings and Long-Term ROI

From a purchasing standpoint, twist tie tying machines offer clear financial and operational value, far beyond just automation.

Rapid Return on Investment

The initial outlay is quickly offset by your savings in manual labour, reduced packaging errors, and accelerated production rates.

Ideal for operations looking to scale without proportionally increasing workforce costs.

Efficient and Predictable Resource Use

Wire consumption is consistent and optimised, allowing procurement teams to forecast material needs with precision.

No wastage from overuse or inconsistent manual tying.

Durable, Low-Maintenance Machines

Designed for longevity with few consumables and low maintenance demands.

This results in a low total cost of ownership, which is ideal for lean operations.

Lower Compliance Risks, Higher Reliability

Helps maintain regulatory compliance in tightly controlled industries like food and pharmaceuticals.

Reduces the risk of costly recalls, fines, or downtime caused by packaging inconsistencies or hygiene issues.

Case Study

Let’s consider a small bread packaging business — Bakery ABC.

The Problem

Manual twist tying capped output at just 20 bags/minute

Frequent seal inconsistencies led to shorter shelf life

Labour costs were rising with two full-time packers on shift

The Switch

In early 2025, Bakery ABC installed a compact twist tie tying machine with conveyor integration and biodegradable tie compatibility.

The Outcome

Packaging speed jumped to 50 bags/minute

Seal consistency improved, reducing product complaints

Only one operator now runs the full packaging line

They achieved ROI in under 3 months

Final Take

For Bakery ABC, a simple automation move delivered faster output, better quality, and real savings — proving how even small businesses can scale smartly in 2025.

Key Considerations When Choosing a Twist Tie Tying Machine in 2025

As twist tie tying packing machines become central to automated packaging, selecting the right model for your operation requires a strategic approach. Here’s what to evaluate before investing:

Match Throughput with Production Demands

Ensure the machine’s tying speed aligns with your packaging line’s output — bottlenecks can undermine automation gains.

Look for models with adjustable throughput settings to accommodate fluctuating demand.

Material Compatibility and Sustainability

Check for support across various tie materials, including plastic, paper-coated, and biodegradable options.

Flexibility here ensures compliance with both product-specific and regional sustainability mandates.

Integration Capabilities

The ideal machine should seamlessly connect to your existing conveyors, robotics, or automation infrastructure.

Prioritise plug-and-play models for minimal downtime during implementation.

Certified for Safety and Cleanliness

For food and pharmaceutical packaging, look for hygienic, easy-to-clean designs.

Ensure machines meet standards like GMP, HACCP, or IP65, guaranteeing safe use in regulated environments.

Reliable Service and Spare Part Availability

Choose suppliers offering strong after-sales support, including local technicians, readily available parts, and digital maintenance tools.

This ensures operational continuity and quick issue resolution.

Smart Features for Data-Driven Packaging

Modern machines offer sensor integration, real-time analytics, and remote diagnostics.

These features support predictive maintenance, improve performance tracking, and reduce unplanned downtime.

Conclusion

Automation isn’t optional in 2025’s fast-paced, sustainability-driven packaging world. Twist tie tying machines deliver a powerful mix of cost-efficiency, consistency, and adaptability.

They offer:

- Precise control and uniform results

- Reduced waste through smart resource use

- Improved quality and regulatory compliance

- Fast ROI with long-term cost benefits

They’re now central to streamlined, future-ready packaging operations.

FAQs:

1. What types of twist ties can these machines handle?

Modern twist tie machines are compatible with plastic, paper-coated, and biodegradable wire ties. Many 2025 models are designed to support eco-friendly materials in line with sustainability regulations.

2. Are twist tie machines suitable for small businesses?

Yes, there are compact and tabletop versions ideal for lower-volume operations. They offer a cost-effective way to improve consistency and reduce manual effort.

3. How do twist tie machines improve hygiene in food packaging?

They eliminate direct hand contact with the tie area, reducing contamination risks. Most machines are also built to meet GMP and HACCP hygiene standards.

4. Can twist tie packaging machines be integrated into existing production lines?

Most machines are modular and can be connected to conveyors, sensors, or robotic arms. They’re built for plug-and-play integration into modern automated systems.

5. What maintenance is required for a twist tie tying machine?

Routine maintenance typically involves cleaning, checking tension settings, and replacing worn tie spools. Many newer models offer self-diagnostics and alert systems to simplify upkeep.

References:

https://dataintelo.com/report/global-twist-tie-machine-market

https://www.bedford.com/blog/choosing-the-right-twist-tie-machine-for-your-application/