If you’re considering using a versatile VFFS machine to aid your production, do you truly understand what it can do? Today, I’ll take you on a deep dive into VFFS machines, whether you’re completely new to them or want to learn more in-depth. Save this guide, and you’ll have all the information you need to understand it.

The History of VFFS

The first VFFS machine dates back to 1936 when Walter Zwoyer obtained a patent while working at the Henry Heide Candy Company. In 1950, he added an automatic weighing system to the VFFS, creating an integrated weighing and packaging machine. Over the decades, as technology has evolved, the VFFS has been continually improved to incorporate the technological advancements of each era. These improvements were made to meet the growing market demand. Today, the VFFS holds an important position in the packaging machine industry due to its versatility, reliability, efficiency, and safety, and it is used in multiple industries to meet human needs.

What is the Vertical Form Fill Seal Machines(VFFS)?

In your traditional understanding, do you think of vertical machines as simply for packaging products, with no knowledge of other functions? However, the reality is that a Vertical Form Fill Seal (VFFS) Machine is an automatic packaging machine capable of making bags, filling, sealing, cutting, and printing production dates/batches automatically. It uses a thermoplastic film to create packaging containers through heat sealing and packages a variety of contents including granules, powders, liquids, and viscous materials.

Thanks to this packaging, your products can be protected against moisture, mold, contamination, and oxidation, thereby extending their storage life. Therefore, the invention of the vertical machine has greatly satisfied people’s demand for a certain shelf life of products, enhancing the quality of life.

How many parts of the VFFS Machine?

You might only know that a vertical machine primarily involves loading and unloading, but there’s much more to it than that. A vertical form fill seal (VFFS) machine mainly consists of a material feeding mechanism, a film supply mechanism, a film drawing, and forming mechanism, a horizontal and vertical sealing mechanism, and auxiliary equipment.

Weighing and Dosing Systems

Component One: Material Feeding Mechanism

This consists of a storage hopper, multiple-position volumetric cups, a feeding gate, and the cups themselves.

Main Function: The storage hopper holds the material. The multiple-position volumetric cups are used for weighing the packaging weight. Under detection and control, within permitted limits, the material moves from the conveying equipment into the storage hopper and the volumetric cups. Once the quantity is adjusted, the feeding gate sends the material to the secondary feeding and into the packaging bags.

Metal Detectors and Check Weighers

Component Two: Film Supply Mechanism

This includes the film roll, pre-storage film mechanism, and a correction mechanism. Photocells for detection and film release help to pre-store and ensure the film maintains tension during drawing and forming. The correction mechanism prevents the film from deviating during transmission.

Film supply organization

Component Three: Film Drawing and Forming Mechanism

This consists of a collar-forming device and a film transport mechanism. Different forming collars are used depending on the package size.

Secondary packaging integration

Component Four: Horizontal and Vertical Sealing Mechanism

The sealing mechanism consists of vertical sealing, horizontal sealing, and cutting of the bags. Packaging speeds are up to 70 packages per minute, driven by mechanical cams or cylinders. For speeds exceeding 70 packages per minute, a servo motor must drive the cam-linkage mechanism. The horizontal seal requires high precision to reduce machine noise during operation.

Now, you should have a clear understanding of the functions and roles of each component of a vertical machine.

Types of Vertical Form Fill Seal Machines

In the markets you are familiar with, vertical machines are generally divided into two main categories: large vertical and small vertical. The biggest difference between them lies in the packaging weight. Small vertical machines are suitable for packaging weights ranging from 1 to 1000 grams/milliliters. For weights exceeding this range, it is generally recommended to use a standard vertical machine.

Regular Vffs Types

Image 1 shows a standard vertical machine, which features a collar-forming structure (Figure 1.1). The collar flips from the outer surface, creating a forming mechanism that has significant movement resistance. Single films are easily stretched and deformed with this mechanism, but it is better suited for composite films. However, it is more challenging to design and manufacture, and it does not accommodate changes in specifications easily. It is widely used in vertical packaging machines or for forming small-measurement bags.

Mini types Vffs

Image 2 depicts a mini vertical machine, which primarily uses two types of formers: the U-shaped former and the trunk-shaped former (Figures a and b).

The U-shaped former (Figure a) is a modified version of the triangle formed, used for vertical sealing on three or four sides. It is better suited for single film stress conditions and offers a broader range of bag types and applications than the triangle former.

The trunk-shaped former (Figure b) combines features of both the collar and triangle formers and is an improved version of the U-shaped former. It is used for forming flat bags with three-sided seals on flat, single films. This former offers low movement resistance, short filling distances, strong adaptability to materials, and is easier to design and manufacture. However, it cannot adapt to changes in bag specifications.

Can you now distinguish between the standard Vertical Machines and Mini Type Vertical Machines?

How Does the Vertical Form Fill Seal Machine Work?

Operation of VFFS Machines

Vertical form fill seal (VFFS) machines typically use a PLC (Programmable Logic Controller) system, where parameters are adjusted on a screen to manage the complete packaging process.

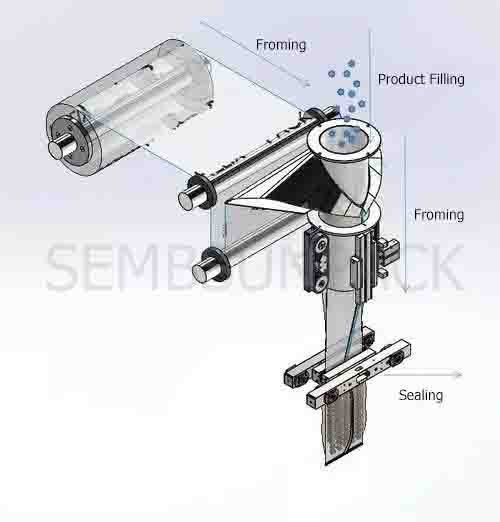

What is the Vertical Form Fill Seal Machines process?

The VFFS packaging process mainly involves the packaging film passing through a tensioning guide mechanism where it is folded to form a pocket. This pocket is then sealed by a heat sealer mounted on the sealing arm. Next, the pocket is pulled down to the length of the next bag by the paper-pulling rollers, and the heat sealer acts again to seal the top of the previous pocket while also sealing the bottom and vertical edges of the next pocket. A cutter then cuts the filled and sealed pocket at the correct seal path position, thus producing the packaged product. This cycle continues to complete the packaging operation.

Types of Bags and Pouches Formed

Film types and their Properties (Polyethylene, BOPP, Laminates)

Aluminum film and non-aluminum film:

Vertical machines are suitable for roll films, also known as composite films, automatic packaging films, automatic packaging roll films, composite roll films, and composite packaging films, etc. They are made by bonding two or more layers of film, hence they are also called composite films (or laminated films). Roll films can generally be divided into two main categories. One category is called aluminum film, which is an aluminum-plastic composite film containing aluminum foil (AL), aluminum-coated film (VMPET), or aluminum-coated CPP (VMCPP). This type of composite film is opaque and appears silver in color when not printed.

Comparison of Film Types

The other category is non-aluminum films, which are ordinary composite films without materials like aluminum foil or aluminum-coated film. These composite films are transparent when not printed.

Packing Bag Types

Vertical machines can typically make various types of bags such as 3 sides sealing bags, 4 sides sealing bags, pillow bags, gusseted bags, block bottom bags, hole punched pillow bags, hole punch stand-up bags, side sealing stand-up bags, chain bags, zig-zag bags, stick bags, and triangle bags. If you are unsure about the type of packaging bag you need, you can contact us. Provide your requirements, and we will analyze them for you.

VFFS Application

A.Suitability of Different Products

1. Solids: Often referred to as granules, solids are widely used in the food industry, for items such as puffed food, candy, cakes, sunflower seeds, and cereals. For the cosmetics industry, packaging for cotton balls and powder puffs is common. In the medical industry, individual packaging of medicines prevents contamination. What’s more, the hardware industry, screw fittings are also widely used, significantly increasing production output.

2. Powders: Such as milk powder, seasonings, protein powder, and coffee powder, are packaged individually for convenience of sale and portability, which has greatly increased their popularity and boosted sales volumes.

3. Liquids: Such as sauces, McDonald’s ketchup, milk, vinegar, and juices, as well as light industrial detergents and various dyes. All kinds of liquids use vertical packaging machines to extend shelf life and facilitate transportation, which improves the accuracy of packaging measurements and enhances safety to some extent.

If you are packaging liquid products, pay attention to the viscosity. For sauces, viscosity varies, and different devices may need to be added to the VFFS feeding device depending on the viscosity. For example, ketchup contains particles, requiring the addition of stirring and heating mechanisms to the liquid pump to prevent clogging at the discharge port. In contrast, orange juice, which contains no particles and is not very viscous, does not require a heating mechanism.

Small bag packaging is also widely used due to its low cost, variety of forms, and convenient carry features, meeting different packaging standards. The most extensive applications are in the food and cosmetics industries.

Imagine marketing your product in small bags to reach more customers. Isn’t it quicker to get repeat purchases this way, compared to distributing flyers on the streets?

B. Impact of Product Characteristics on Packaging

If you are not packaging the types of products mentioned above but are dealing with irregularly shaped products, you should first measure the dimensions of the product and describe what you want the final package to look like. Then, provide this data to the VFFS packaging machine manufacturers. They will offer you packaging solutions to choose form.

Why do you need a Vertical Form Fill Seal Machines for your business?

What are the Advantages of the VFFS?

1. Fast speed.

2. Safe protection measures are in place; if the hand accidentally touches the cutting area, it will automatically spring open.

3. Moisture-proof, mold-proof, pollution-proof, extending storage life.

How fast does the VFFS work for one minute?

The first vertical machine was invented to facilitate the packaging of candies because it helps extend the storage life of products, prevents re-contamination, and facilitates transportation for sales to distant places. Moreover, a fully automatic vertical machine can significantly enhance production efficiency, to some extent replacing fixed labor and reducing the chances of errors. If you are a production line manager, would you choose an efficient automated packaging machine or an employee who might take leave?

Factors affecting speed mainly include the weight of the product being packaged, whether vacuum extraction is needed, and the method of cutting the bags. Based on experience, a vertical machine can achieve up to 60-70 bags/min when packing empty bags. If the product you are packaging is heavier, the packing speed will correspondingly decrease.

How to Choose The Right VFFS?

Factors to consider when purchasing a VFFS machine

- Production volume

- Product types

- Available space

- Budget

When buying a VFFS machine, you need to be clear about the following points:

Hourly Production Needs: How much output do you need per hour?

Product Characteristics: You need to understand the characteristics of the products you are packaging, differentiating between solids, liquids, and powders.

Production Facility Space: How large and tall is your production facility, and can the machine be properly accommodated?

Budget: Your budget will determine if you can choose a machine with more comprehensive features, which would be useful for expanding production in the future.

Comparison of Different VFFS Machine Manufacturers

In the packaging machine industry, consider which manufacturers you want to choose from and whether their prices fit your budget. VFFS technology is quite mature now, and if you are looking for a brand, their prices will generally be higher. Manufacturers with quality certifications can usually produce packaging machines that meet your requirements.

ROI considerations

When purchasing packaging equipment, you need to calculate your return on investment (ROI) because it concerns your profit. First, you need to calculate the annual cost of your current packaging process. If you buy a new machine, estimate how much additional production it can handle and what the losses might be.

Here’s the ROI formula:

ROI = (Net gains or losses from new equipment / Total cost of the new machine) x 100

For example, if you plan to purchase customized packaging equipment for $300,000 and expect an annual net income of $200,000 (including labor savings and increased throughput profits), your estimated ROI would be:

ROI = ($200,000 / $300,000) x 100 = 66.67%

This can serve as a reference for you to save on labor and increase production in your manufacturing operations.

3 VFFS Troubleshooting You Will Meet

Misalignment

A. Problem: Misalignment of the roll film

Solution: Modern machine manufacturers have updated the color mark positioning, and models above D420 also include an automatic trim function. Additionally, consider what color your roll film is, as transparent films cannot use the automatic editing function. Alternatively, you can manually adjust the axis to reposition the film.

Inconsistent Sealing

B. Problem: Inconsistent sealing

Solution: First, check on the screen to see if the set temperature has changed, then check if the cutter has material stuck to it, causing uneven heating.

Film Tearing

C. Problem: Roll film tearing

Solution: This generally happens when the tension is too high. Check if the belt is slipping. Try wiping off the material with a towel to keep it clean.

How is the VFFS Future?

Future Trends in VFFS machines and packaging technology

Final Thoughts on Optimizing the use of VFFS machines in your Operation

In the packaging machinery industry, the future of VFFS machines holds a pivotal position. Future vertical machines will evolve to better meet human needs with standardized structural designs. Gradually, the movement structures will become highly precise to address faults more intelligently and flexibly. Through computer programming systems, consultation, after-sales service, and detailed product parameter analysis will be handled via internet programming and communication, achieving zero-distance customer service.

FAQ

A: What is the Difference Between HFFS and VFFS?

The working principle of VFFS is vertical, while HFFS operates horizontally.

B: What is the Difference Between the VFFS Machines & Bagging Machines?

VFFS machines form bags from roll film, completing both the filling and sealing processes. On the other hand, a bag machine has already made the bags, allowing the machine to handle the filling and sealing. Typically, these pre-made bags are referred to as premade bags, and machines that package these are called Premade Bag Packing Machines.

C: How to maintenance when you use VFFS for a time?

Over time, it’s inevitable that dust will accumulate on a VFFS machine. It can be wiped off with a cloth because the body of a VFFS is made of 304 stainless steel. Remember to turn off the power before cleaning.

D: What kinds of Optional Functions did you Add?

- Servo Motor: Fast speed, with safety protection and strong controllability.

- Air Shaft: Distributes the tension evenly across the film, preventing it from tearing easily.

- Vacuuming/Nitrogen Gas Addition: Extends the shelf life.

- Standard Ribbon Coding Machine: Prints the production date.

- Pulling Device: For packages over 1 kg, this feature reduces the gravity impact during filling to protect the product.

- Punching: Meets customer demands for product packaging appearance.

- Dust Removal Device: Typically installed in vertical machines that package powders, ensuring clean and hassle-free operation.

- Siemens Motor Control: Provides brand assurance.