How to Use a Horizontal Flow Wrap Machine to Warp a Chocolate Bar?

With the development of the times, chocolate bars have become a household favorite snack. However, do you know how it is packaged?

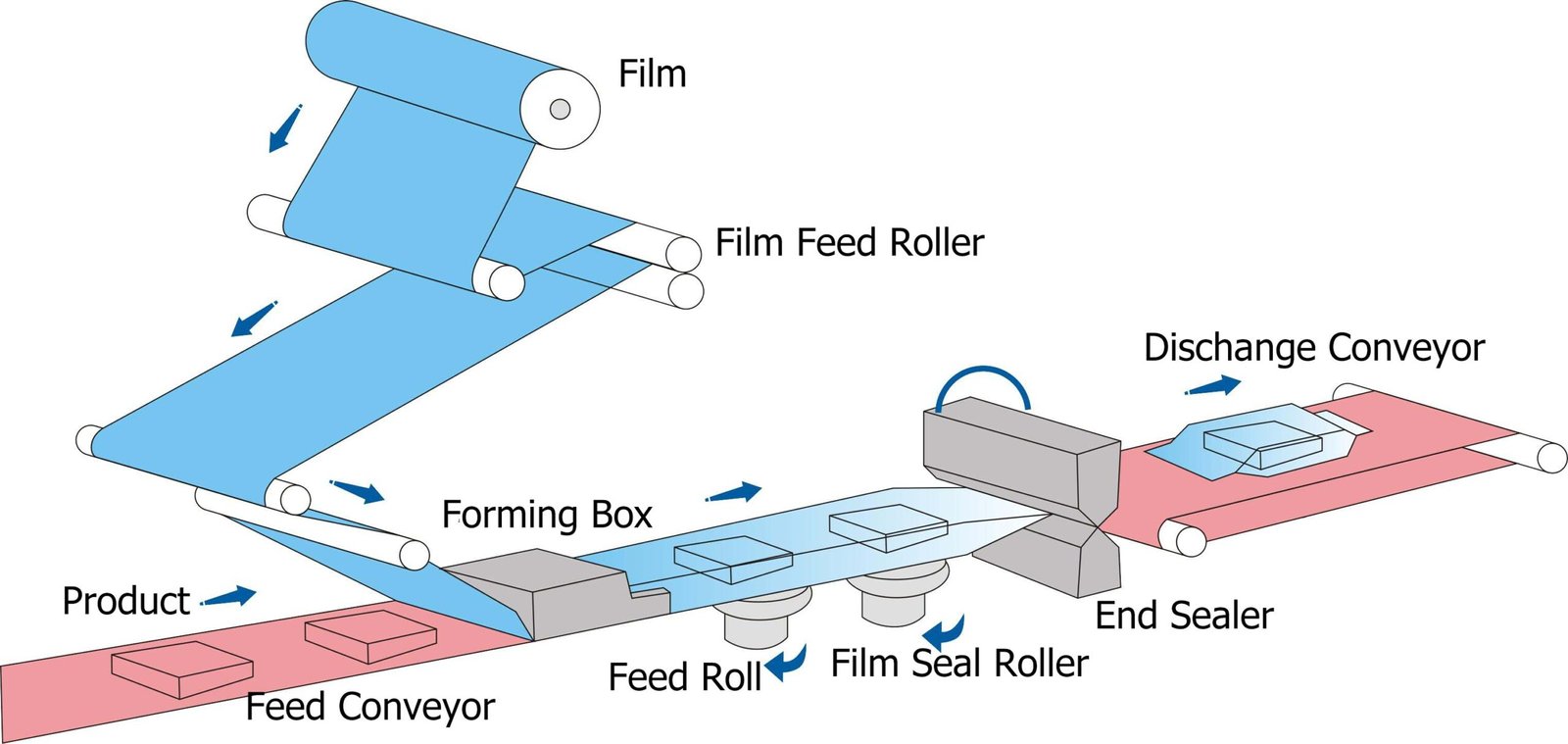

Flow Pack Packaging Machine Working Principle

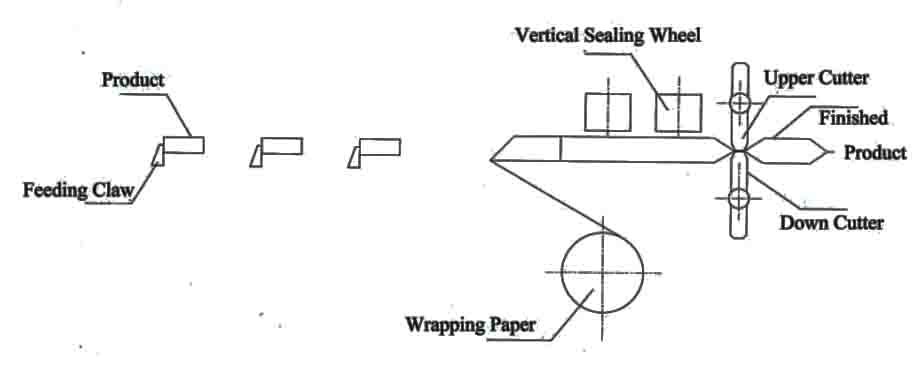

After the chocolate bars have been produced, do you know how they are packaged into attractive bags? The chocolate packaging film passes through a set of rollers into a former to create a cylindrical shape. Each chocolate bar is then pushed individually into the formed film tube by a conveyor push plate. A pair of film-pulling rollers then continuously move it longitudinally. It goes through a longitudinal sealing wheel where it is heat-sealed to complete the vertical seal. After this, the chocolate bar was sent to the cross-sealing and cutting device to be sealed horizontally and cut, finally exiting the horizontal flow wrap machine on a conveyor belt to form a beautiful pillow packing. The entire packaging process is automatic and continuous.

Machine Component

How are the back seals on pillow packing made?

1. Drive System: Comprised of transmission parts and a frame, it currently utilizes dual variable frequency, dual servo, single variable frequency single servo, and triple private service configurations.

2. Feeding Device: Consists of a worktable and material conveyor belts. The worktable panels are located on both sides of the worktable to prevent packaging items from slipping off. The width can be adjusted.

3. Film Supply Device: Positioned either below or above the machine frame, this device is used to install the reel packaging film. The reel’s axial position can be adjusted to align its center with the center of the feeding mechanism. It is equipped with an automatic centering feature.

4. Former: Also known as the bag maker, it continuously feeds sheet film into the packaging machine, supporting it in a cylindrical shape to wrap the items. It is a core component of horizontal pillow pack machines.

5. Vertical Sealing Device: Also known as the back sealing device, it has three pairs of opposing rotary wheels that traction the packaging film, perform heat sealing, and fold the edges.

Depending on the film supply method, the vertical sealing device comes in two structural forms:

- Top Film Supply: The vertical traction and sealing of this device are located below the materials. It is primarily used for packaging tray-bearing items like mooncakes and fragile biscuits.

- Bottom Film Supply: Located above the material conveyance plane, here the traction, sealing, and folding occur above the materials. This setup minimizes heat effects on the materials, making adjustments and maintenance more convenient and applicable to a wider range of uses.

Top Film Supply

Bottom Film Supply

6. Cross-Sealing Device: Also called the end seal device, it completes the cross-sealing and cutting here.

- The sealing patterns come in three types: horizontal, straight, and net patterns.

- The cutting styles include four types: straight cut, serrated, V-shaped opening, and continuous (with easy tear holes).

Pay Attention Before Buying

If you are also interested in using a pillow pack machine to package your chocolate bars, you should consider the following factors:

- Shape and Size of Your Chocolate Bar: What is the current shape and size of your chocolate bar, and how many do you want to package together?

- Packing Speed: How many packages do you want to produce per minute?

- Production Requirements: Whether the machine is to be used as a standalone unit or integrated into a production line.

- Material Inflow and Outflow: The direction of material flow, whether it is left-to-right or right-to-left.

- Blocking Device Requirements: In addition to the main machine, if you want any special functions like vacuuming out excess air during packaging, adding nitrogen, or applying your QR code or brand logo.

- Requirements for the Packaged Product: The type of seal pattern needed, the pattern on the packaging film, whether you need continuous or individual distinct patterns, and if the packaged product will undergo heat shrink packaging after being pillow packed.

Other Application

This kind of chocolate bar wrapping machine can package chocolate bars, what else can this flow packaging machine handle?

This fully servo-controlled chocolate bar wrapping machine can also package items like Honduras chips, candy packing, popcorn packing, beef jerky, instant noodles, biscuits, cakes, frozen food, seafood, soap, and egg yolk pies at high speeds. This fully servo-controlled flow packaging machine is easy to operate, offers high precision control, and features a touchscreen for intuitive data reading.

It includes an empty bag prevention feature to save on packaging materials. The machine has a simple mechanical structure, making it easy to maintain with a low failure rate, fast speeds, good stability, and low noise. It can be connected to various automatic feeding devices, offering good scalability and easy adjustments, and it allows for data storage and changing packaging products.

Finally, How do you want your product to be packaged?

If you want to know more about the machine, please contact us.