How Many Types Of Flexible Pouches Do You Know?

As we all know, the most familiar and common flexible pouches are 3 Side Seal Pouches, 4 Side Seal Pouches, Stand Up Pouches, and Pillow Pouches. due to the development of printing nowadays, various kinds of flexible pouches have been designed to provide For Industrial Packaging, it’s important to have a choice of pouches that can be customized.

For Industrial Packaging, choosing the right pouch is an important step, although we are a packaging machinery factory, but often ask customers how to choose flexible pouch packaging packaging their products, if it is the use of machines to pack products, packaging pouches, whether there are requirements for the material and so on a series of flexible pouches questions. flexible pouches.

Today, we take you to recognize the market emergence of Flexible Pouch, hope that after you read this article, you will know the types of flexible packaging pouches and find the right bag for your industry.

What Is Pouch Flexible Packaging

Pouch Flexible Packaging is one of the most widely used packaging methods in the contemporary packaging industry. It can package both food and non-food products, and is loved and used by a wide range of businesses for its lightweight and aesthetically pleasing features. Its flexibility allows it to package powders, liquids, and granules, realizing packaging versatility. So how do manufacturers choose the right packaging tape for themselves? Below is an overview of the types of flexible packaging pouches available on the market.

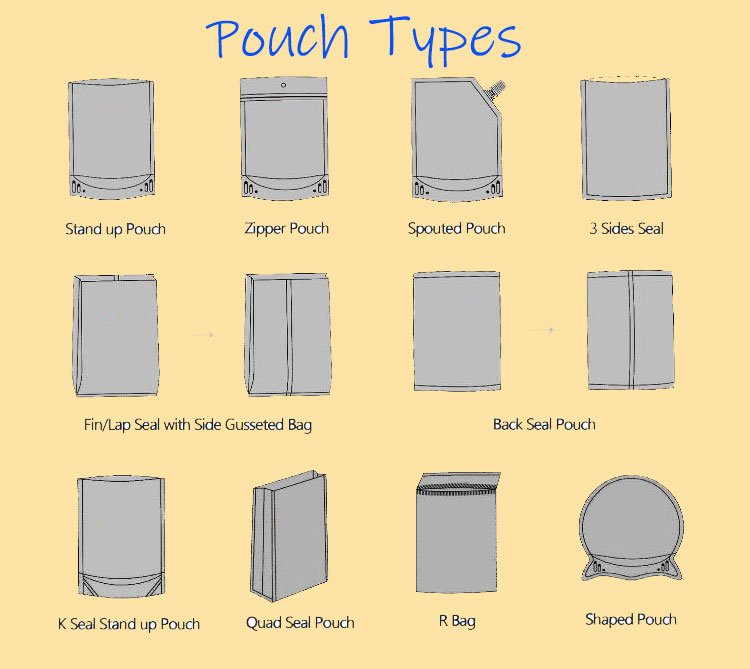

Types of flexible packaging pouches

Different flexible packaging pouches have their own advantages and features, so they give different products different experiences to consumers, so most manufacturers also seize these to cater to consumer demand in order to increase sales.

1.Stand Up Pouches/Stand-Up Pouch / Doypack

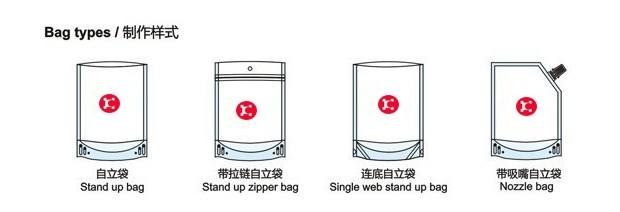

This is the most typical flexible packaging stand up pouches and also the most basic one. Different buyers in different areas have different names, in fact, stand-up pouch, and doypack are expressed is the same prefabricated bag. It has the characteristics of the bottom can be held open, do not need to rely on what, the bag can stand up on its own, to maintain an upright state, packaging products can be placed through the opening above the material and then sealed, to achieve the effect of simple, beautiful and practical, commonly used in the food industry packaging cookies, fudge, potato chips, etc., in the daily necessities of the industry have laundry supplies. This one can not be reclosed or repeated opening of the four side seals flexible stand-up pouches.

2. Zipper Pouch

This you literally not difficult to see, this flexible pouch is with a zipper is, and the basic models of the stand-up pouch type increased a blockade, in order to allow the bag to repeat closed and reopen the use of the user to facilitate the use. Often used in granular and powdered products, such as: nuts, candy, cereals, nutritional flavorings and so on.

Because the closure of the zipper is not very good, the liquidity is too strong and volatile products are not suitable for the use of Zipper Pouch packaging.

3. Spout pouch

flexible packaging spout pouch bag is a stand-up pouch with its own spout, in which the spout pouch bag is a pouch type that can control the dosage well and facilitate pouring and taking products, sealing and opening repeatedly. There are 3 common forms in your daily life (as shown in the picture), left diagonal with spout, right diagonal with spout and right center with spout.

But when you are picking a packaging machine for the bag type with a nozzle, you have to note that the center with a nozzle can only be filled by rotary bag packaging machine and the beveled side nozzle can be packed by using a regular horizontal bag packaging machine, because the top of the bag has enough position for the bag opening function of the packaging machine to open. If you are not sure whether your stand-up pouch type is compatible with the packaging machine, no need to be anxious, you can contact us, provide us with your bag size, we will give you a detailed explanation of the program.

4.Shaped pouch

With the need to make bags more aesthetically pleasing and to bring a sense of freshness to the customer, many bag manufacturers have designed a variety of bags, which we collectively refer to as irregular-shaped pouch, usually made of aluminum foil. For example, if you understand that I produce yogurt-flavored gummies and use stand-up pouches, the designer has cleverly designed a bottle shaped pouch to package the gummies. The shape of this type of pouch is not 4-sided but has curves to form an irregular shape, you can also understand a traditional quadrilateral shape.

Many functional pouches on the market also use this type of bag, we call it flexible beverage pouch, because it is easy to carry and provide a fixed dosage to meet the needs of consumers, but also a flexible plastic pouch beverage container to package beverages.

We call this type of irregular bag Shaped pouch, which is closer to human aesthetics and enriches the diversity of stand-up pouches.

5. Gusseted Pouches (Side Gusset And Bottom Gusset)/ Side gusset pouch/Flat bottom pouch

Gusseted Pouches (Side Gusset And Bottom Gusset)/Side gusset pouch/Flat bottom pouch There are many descriptions of Gusseted Pouches, you can refer to the subheadings above to determine the expression you commonly used where it is, its 4 corners will be made into a vertical shape, the top is closed in a horizontal sealing way to ensure that the bag is more stable in the placement, to avoid the gravity to cause the sinking or collapsing.

Corner bags have the advantages of good sealing, not easy to break, high weight capacity, and are used for packaging heavier or long-term preservation of goods, such as chemicals, food, medicine and so on. The common ones are flour, feed, sunflower seeds, cookies and so on.

6. Valve pouch with valve stand-up pouch

This bag type in the base of the stand-up pouch plus a valve port, this valve port can be from the inside breathable out, the outside air can not go in, is a one-way valve. Widely used in the coffee industry, the coffee beans themselves contain acids, proteins, carbohydrates, etc., after roasting, Mellard reaction and a series of chemical reactions will produce carbon dioxide, if not discharged in a timely manner, the coffee beans will be affected by the role of carbon dioxide, which in turn directly affects the freshness of the coffee beans, thereby affecting the brewing process of water absorption saturation effect, extraction of the outlet is not enough to enrich the coffee liquid! The coffee beans will be affected by the carbon dioxide effect, which will directly affect the freshness of the coffee beans, thus affecting the water absorption and saturation effect during the brewing process, and extracting the coffee liquid with less rich taste. But the roasted coffee beans can not be used directly, because the roasted coffee beans need to maintain the bean period, this period needs to release carbon dioxide.

This type of stand-up pouche to avoid the Zipper Pouch repeatedly open or close the product to bring moisture, but also to reduce the inconvenience of carrying the canister.

7. Pillow Pouches

Pillow pouches are the longest-used pouch type in the packaging industry, this use of pouch packaging machine: vertical machine and flow wrap machine, these 2 packaging machines are the earliest class of machines in the packaging industry.

This bag is an affordable one of the packaging, by the roll of film through the packaging machine into a bag, due to the pillow machine and vertical machine has the function of bagging, packaging manufacturers only need to install the roll of film, the machine will complete the bagging, down the sealing and a series of work.

You can see in the snack food industry of potato chips, cookies, individually wrapped, bread baking, and other snack food packaging, the hardware industry has a screw cap, screws, furniture accessories, etc., daily necessities industry has soap, paper towels, razors, vegetables, fruits, single or multiple packaging.

8. 3 Side Seal Pouches

This category is a three-sided sealing design, reasonable structure, simple, easy to operate, and the bottom can stand independently. Commonly, this type of bag is suitable for powder, granules of small objects, the application of food, hardware, disposable medical supplies, beverage industry, packaging crafts, gifts, and other products.

9. 4 side seal pouch

Four sides seal is the most common type of bag on the market, 4 side seal, the bag can not stand up independently, but the price will be cheaper than other stand-up pouch styles.

Often used in pre-made vegetable soups, packaging clothing, face masks and other products.

10. Liquid Pouch Packaging: Sachet

Pouches for direct packaging of liquids need to contain high strength, bursting and impact resistance properties, protection of the liquid inside the package under certain circumstances and a good seal. Commercially available liquids such as juices, jams, beverages, laundry detergents, cooking oils, and other liquids with flowability are packaged in this type of pouch.

At the same time, many manufacturers also use this type of bag packaging sachets of sauces, used in the rapid development of fast food industry is a good choice.

11. Quad Pouch / Eight Side Seal Bag

Quad pouch has the advantages of a variety of film materials and flat bottom standing effect of the finished product, than the traditional stand-up pouches to increase the volume, is the new choice of the traditional film stand-up pouches upgrade. Can add zipper, easy to reuse, to avoid the shortcomings of the organ bag can not add zipper, but also can add one-way exhaust valve, become Quad Valve pouch.

The market can be packaged nuts, cereals, peanuts and other products, upgraded Quad pouch will make the goods on the shelf bright.

12. Kraft Pouch/Kraft Paper Pouch

Kraft pouch is a recyclable flexible pouches, the use of kraft paper non-toxic, tasteless, non-polluting made of Kraft Paper Pouch, is a high-strength, highly environmentally friendly stand-up pouch type, in line with the world’s environmental awareness, to give consumers a real sense of touch.

Generally combined with the design of the zipper, so that the kraft paper pouch reuse, common beef jerky, dried small fish, various local specialties snacks quickly packaged and beautiful.

13. Retort Pouch Steaming pouch

flexible retort pouch is a special food packaging material, mainly used for packaging food that requires high temperature steaming. The common materials on the market are nylon composite retort pouch and polypropylene composite retort pouch. Used in prepared food, such as cooked food, meat, soy products and so on. Cooking bags of various materials, each material has its unique characteristics and applicable scenes, can meet the needs of different food packaging.

Nylon composite flexible retort pouch packaging is resistant to high strength and high heat resistance, and can package instant noodles, rice, rice balls and other convenience foods that require high-temperature sterilization treatment.

Polypropylene composite flexible retort pouch packaging good heat resistance and pressure resistance, can be packaged vegetables, fruits and other foods that require high-temperature treatment.

14.Vacuum Bag / Vacuum Brick Bag

Vacuum bag according to the characteristics of the packaged goods, preservation conditions and the degree of protection required to choose the material, we commonly have PET, PA, PE, aluminum foil.

PET vacuum bag is a kind of colorless transparent, glossy vacuum bag, it has excellent mechanical properties, friction resistance, high and low temperature resistance, chemical resistance, oil resistance, air tightness and aroma retention.PET vacuum bag is often used in the outer layer of the cooking packaging materials, has good printability.

PA vacuum bags have very tough characteristics, high tensile strength and tensile strength, good resistance to heat, cold, oil and organic solvents, abrasion and puncture resistance. Nylon vacuum bags are suitable for packaging hard items, good oxygen barrier properties effectively extend the shelf life of food, greasy food, meat products, fried food and other manufacturers commonly used one of the bag type.

PE is a thermoplastic resin made by polymerization of ethylene, with low transparency, hard feel and brittle sound. It has excellent gas barrier, oil barrier and aroma retention properties, but is not suitable for high temperature and refrigerated use.

Polyethylene vacuum bag is suitable for ordinary vacuum packaging without special requirements, one of the first choice for household vacuum bag.

Aluminum foil composite vacuum bag has a layer of aluminum foil added between the inner and outer layers, which has good barrier and heat sealing properties, good light shielding, and is suitable for food packaging that is sensitive to light and oxygen. Aluminum foil can completely isolate light and oxygen, effectively preventing food from discoloration and tastelessness caused by light and oxidation. Meat, seafood manufacturers will choose this type of vacuum packaging bags.

How to choose a proper pouch for your business

After reading the above article, you may still not be able to distinguish what kind of flexible pouch packaging, you can put your product characteristics and what you want to achieve the effect of the finished product packaging, but I give an example, you may understand. For example: I need to package candy, the bag needs to be easy to display on the shelf, and each package with production date, official QR code and other manufacturer information, and secondly, the bag needs to be zippered, easy to open and seal, the weight of each packet in 250-500 g. Fill in the form to the right with this information, so that we can initially suggest what type of pouch to use, to save time for you.