Many people can’t distinguish between different types of shrink wrap film, let alone their prices. If you need shrink wrap film to package your products, it’s essential to understand how to calculate the cost of shrink wrap film, as it has a significant impact on your profit.

What is Shrink Wrap Film

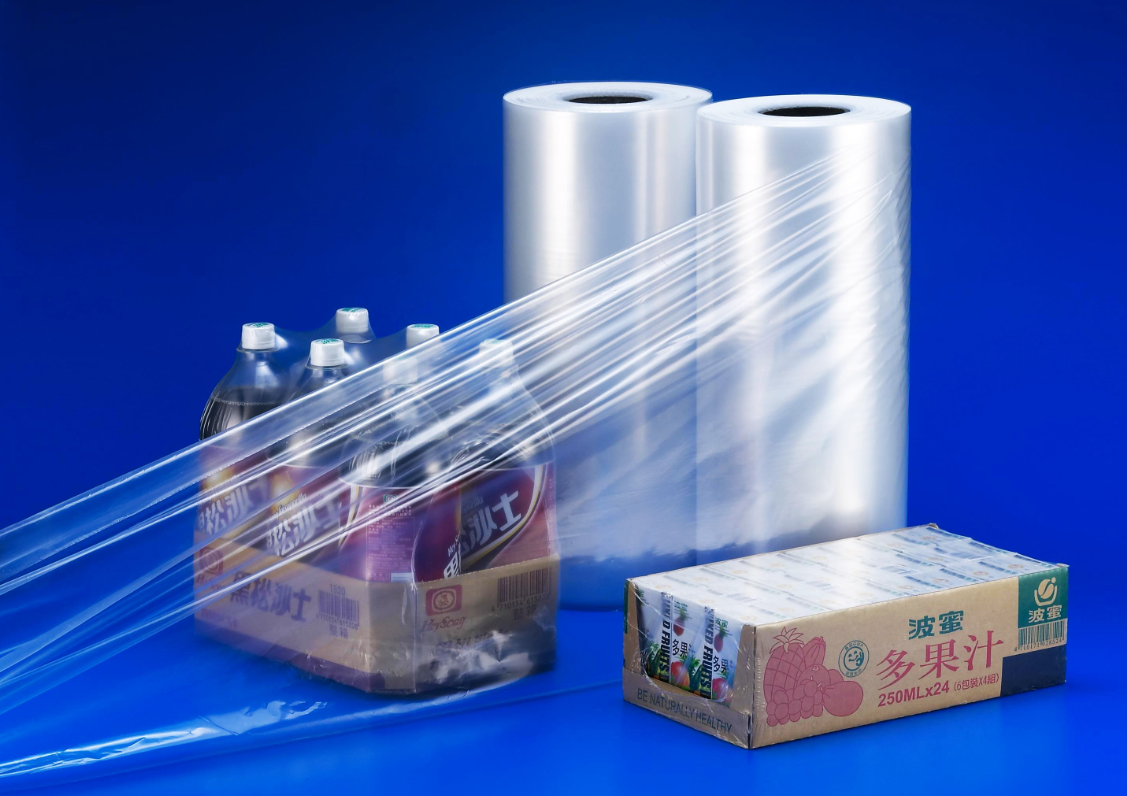

Shrink wrap film, as the name suggests, is a type of film that shrinks when heated. It’s like the film that tightly wraps around a new smartphone box. This film shrinks when heated, wrapping snugly around products.

Initially, there was PVC shrink film, which has evolved into the more commonly used types today, including PE, PP, PET, OPP, PVDC, and POF multilayer shrink films. These types are:

PE shrink wrap film

PVC shrink wrap film

POF shrink wrap film (multilayer co-extruded polyolefin shrink film)

OPS shrink wrap film

PET shrink wrap film

What Affect The Price Of Shrink Wrap Film?

The main factors affecting the price of shrink wrap film are threefold: the type of film, the length of the film, and the quality of the film.

First, you need to be clear about the common types of shrink wrap film available on the market and their respective uses.

Types of Shrink Film: Polyolefin, Polyethylene, and PVC

Polyethylene Shrink Wrap – PE

This film is chemically known as polyethylene shrink film. PE is divided into three categories: LDPE, HDPE, and LLDPE. Although they all belong to PE shrink film, there are significant differences among them. PE shrink film is characterized by good flexibility, strong impact, and tear resistance, and is not easily damaged. It is moisture-resistant and has a high shrinkage rate, making it commonly used by many businesses for the outer packaging of bottled water, alcoholic beverages, canned goods, fabrics, and various beverage products. The main purpose is to protect the products from damage during transportation.

Polyolefin Shrink Wrap – POF

This film, known as multi-layer co-extruded polyolefin shrink film, is a newer type of film and a replacement for traditional PVC shrink film. It has high surface gloss, good flexibility, strong tear resistance, and uniform heat shrinkage. It is very suitable for use in fully automatic high-speed packaging machines.

PVC Shrink Wrap

This film is chemically known as polyvinyl chloride shrink film. It has characteristics such as being rainproof, fire-resistant, anti-static, easy to mold, high transparency, good gloss, and a high shrinkage rate. However, after shrinking, this film becomes brittle and very easy to break.

PVC is a widely popular and extensively used synthetic material. Among materials that can produce three-dimensional surface films, PVC is the most suitable. Due to its unique properties and the advantage of low investment with high output, PVC is widely used in the construction and packaging industries.

PET Shrink Wrap

PET shrink wrap is a new type of shrink packaging material. It is easy to recycle, non-toxic, tasteless and has good mechanical properties. Especially in countries with strong environmental awareness, PET has become an ideal substitute for polyvinyl chloride (PVC) shrink film due to its environmental protection characteristics.

The Width of Shrink Film

You must know that shrink film specifications are usually expressed as a combination of width and thickness.

For example, “20mic x 300mm” indicates a shrink film with a thickness of 20 microns and a width of 300 millimeters. Typically, the common thickness of shrink film available in the market ranges from 15 to 30 microns, and the width generally ranges from 200 to 1000 millimeters.

Shrink film also comes in various colors, such as transparent, white, black, etc. This can be customized according to the customer’s requirements.

Factors to Consider When Calculating Shrink Film Dimensions

When calculating the dimensions of shrink film, you need to consider several key parameters:

1. Product Dimensions: You need to know the length, width, and height of the product you want to package. These are the most basic parameters for calculating the shrink film dimensions.

2. Type of Shrink Film: Determine which type of shrink film you will use. You need to know the shrink rate of this film, which is usually expressed as a percentage. The higher the shrink rate, the smaller the dimensions after shrinking.

3. Shrink Film Thickness: The thickness of the shrink film affects its shrink rate. Generally, the thicker the film, the lower the shrink rate.

4. Heat Shrink Temperature: Since the shrink performance of the film primarily depends on thermal principles, you must know the heat shrink temperature. The heat shrink temperature determines when the shrink film will start to shrink.

How to Calculate the Amount of Shrink Film Needed for Packaging

Here is the method to calculate the amount of shrink film needed to package a product:

Area Calculation: Calculate the area of the product to be packaged. Area = Length × Width, where Length refers to the length of the package.

Roll Length Calculation: Calculate the length of the shrink film roll needed. Roll Length = Area ÷ Thickness, where Area is the area of the shrink film required to completely wrap the product.

Surface Area Calculation: Calculate the surface area of the product to be packaged. Surface Area = Length × Width × 2 + Width × Thickness × 2 + Length × Thickness × 2.

If you find these calculations daunting, don’t worry! You can click on the following text “Which is the fastest way to calculate your shrink film width?” to quickly determine how much shrink film you need to package your product.

Thickness of Shrink Wrap Film

You may have heard that there are many types of shrink films, and different thicknesses of shrink films are also available. Today, we’ll explain the most common four types of shrink films. It’s important to understand these, as they might be exactly what you need:

PE Shrink Film: Thickness ranges from 0.018mm to 0.03mm, and the thickness can be customized according to customer requirements.

PVC Shrink Film: Thickness ranges from 0.018mm to 0.05mm, suitable for general shrink packaging, including shrink labels for beverages and other products.

POF Shrink Film: Available in specifications such as 10μm, 12μm, 15μm, 19μm, 25μm, 30μm, and 38μm, suitable for high-end product packaging such as cosmetics.

PET Shrink Film: Common specifications include 12μm, 25μm, 36μm, 50μm, 75μm, 100μm, 125μm, 150μm, 175μm, 188μm, and 250μm. It is used by many electronics manufacturers for the surface protection of electronic products and in other areas that require transparency and durability.

Shrink Wrap Roll Size:

(item width + item depth) x 2 x 1.1 ÷ 2

Example: 10 in wide product +20 product depth = 30

30 x 2 = 60

60 x 1.1 = 66

66 ÷ 2 = 33″ Wide Roll Recommended

Shrink Temperature of Various Shrink Films

| Shrink Films Types | POF | PET | PVC | PE |

| degree℃ | 130-150 | 120-180 | 80-100 | 120~180 |

| 0.015mm | 150℃ | 120℃ | ||

| 0.02mm | 170℃ |

Summary: Shrink Temperature of Shrink Films

In general, the shrink temperature of shrink films ranges from 60°C to 110°C:

Low-Temperature Shrink Films: Shrink at temperatures between 60°C to 85°C, suitable for packaging temperature-sensitive foods and pharmaceutical products.

High-Temperature Shrink Films: Shrink at temperatures between 90°C to 110°C, ideal for hot food packaging and frozen food applications.

It’s important to choose the right shrink film based on the specific requirements of your packaging application.

Film Types Comparison: POF vs. PVC vs. PE

| film Types | POF | PVC | PE |

| Horizontal Shrink Rate | Greater than 50% | Begins shrinking at 50°C, horizontal shrink rate: ≥ 35% | Initial shrinkage temperature is 180°C, 0% to 50% |

| Vertical Shrink Rate | Greater than 50% | 15% | 50%~85% |

| Thickness (mm) | 0.012-0.03 | 0.015-0.2 mm | 0.03~ 0.2mm |

| Advantage | Good transparency, good flexibility | Good transparency, suitable for printing | Good flexibility, high tensile strength, low transparency |

| Application/Shrink Film Characteristics and Uses | Packaging delicate products like cosmetic boxes, disposable utensils, handicrafts; not suitable for heavy items | Producing various sizes of tubular film, single-sheet film, and folded film, used for packaging industrial supplies such as doors, windows, and stainless steel | Suitable for grouping packaging and heavy item packaging; not suitable for packaging items that are not resistant to high temperatures |

Different kinds of Shrink Wrap Machine Costs and Performance

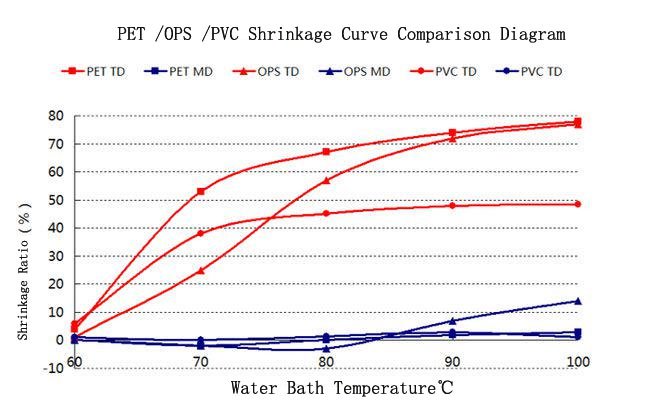

| Performance or Indicator | PVC | OPS | PET |

| Stiffness | Good | Poor | Excellent |

| Density | 1.36 | 1.05 | 1.32 |

| Horizontal Shrinkage Rate (100°C, 10s) | 48%-50% | 65%-75% | 60%-70% (medium shrinkage), 70%-80% (high shrinkage) |

| Shrink Wrap Machine Price | Excellent | Poor | Moderate |

| Printing Ink Price | Excellent | Poor | Excellent |

| Chemical Resistance | Excellent | Poor oil and drug resistance | Poor alkali resistance |

| Shrinkage Effect (Steam) | Excellent | Good | Good |

| Shrinkage Effect (Electric Heating) | Excellent | Excellent | Moderate |

| Shrinkage Rate | Good | Excellent | Excellent |

| Wear Resistance | Good | Moderate | Excellent |

| Resistance to Natural Shrinkage | Moderate | Poor | Excellent |

| Printing Gold and Silver Performance | Excellent | Poor | Excellent |

| Wrinkle Effect | Excellent | Excellent | Good |

| Tear Line Processing | Good | Excellent | Moderate |

| Tear Line Easy Tear | Good | Excellent | Poor |

| High Temperature Resistance (secondary shrink packaging) | Good | Poor | Excellent |

| Transport Stability | Moderate | Poor | Excellent |

| Storage Stability | Excellent | Moderate | Good |

| Environmental Protection | Poor | Excellent | Excellent |

Summary

After reading this article, do you have a better understanding of how to calculate the cost of shrink wrap film? If you’re new to this industry and feeling unsure, don’t worry. Click the link below, and we’ll provide you with a detailed quote based on your needs. Isn’t that a relief for you?

If you want to learn more about heat Shrink Wrapping Machines, you can check out our products below. For further inquiries, feel free to contact our export department.