How much do you know About Polybags? Application And Uses You Should Know

When we think of plastic bags, we often think of them being everywhere in our daily lives. But do you really know what a poly bag is? Is it made of just one material? Is it only use for holding things? Today, let’s talk about poly bags.

What is a Poly Bag?

Why do people often call it a poly bag? Actually, this is its abbreviation. The full term is polyethylene bag. It is a bag made from soft plastic. Due to its lightweight and easy-to-carry nature, it has become the most widely used material in supermarkets and the packaging industry. Do you think a poly bag is just a simple bag? Actually, it’s not. The ordinary bags we see are made from different materials, and the products have varying degrees of flexibility depending on the raw material. Let’s take a closer look at the raw materials used for poly bags.

Poly Bag Materials

Are you wondering what materials poly bags are made of? Why can a small bag withstand different weights? Given its widespread use, could it be harmful to human health? Let’s explore the different aspects of poly bags.

Today, we’ll introduce you to various types of poly bags: HDPE Poly Bags, LDPE Poly Bags, LLDPE Poly Bags, MDPE Poly Bags, and PP.

- “HDPE Poly Bags” means High-Density Polyethylene. HDPE is a highly crystalline, non-polar thermoplastic resin. It appears as a white powder or granule and is non-toxic and odorless.

- “LDPE Poly Bags” means Low-Density Polyethylene, also known as high pressure-low density polyethylene (HP-LDPE). It has a history of over 70 years. As the name suggests, it is low-density polyethylene. It is white, odorless, tasteless, non-toxic, and has a wax-like appearance. It is soft, flexible, and chemically stable.

- “LLDPE Poly Bags” means Linear Low-Density Polyethylene. It is a primarily linear polymer with many short branches. Different manufacturing processes allow it to maintain high strength and toughness while producing thinner films. The film is slightly milky translucent, soft, resistant to low and high temperatures, and has high permeability. Therefore, it is not suitable for long-term storage of oxidizable food.

- “MDPE Poly Bags” means Medium Density Polyethylene. It was produced in the 1970s in the United States using the slurry method. Its synthesis process uses the LLDPE method, with about 5% olefin. It is characterized by long-term strength retention, a density of 0.926-0.953, crystallinity of 70%-80%, tensile strength of 8-24 MPa, elongation at break of 50%-60%, and a melting temperature of 126-135°C. It can be processed using extrusion, injection, blow molding, rotational molding, and powder molding methods.

- “PP” means Polypropylene. It is a polymer made from propylene through a polymerization reaction. It is non-toxic, odorless, tasteless, white, and wax-like, with a transparent appearance. It is flammable, with a melting point of 189°C and a softening point of around 155°C. Its use temperature range is -30 to 140°C. PP is widely used in the production of fiber products like clothes and blankets, medical devices, automotive parts, bicycle parts, pipelines, chemical containers, and also in food and pharmaceutical packaging.

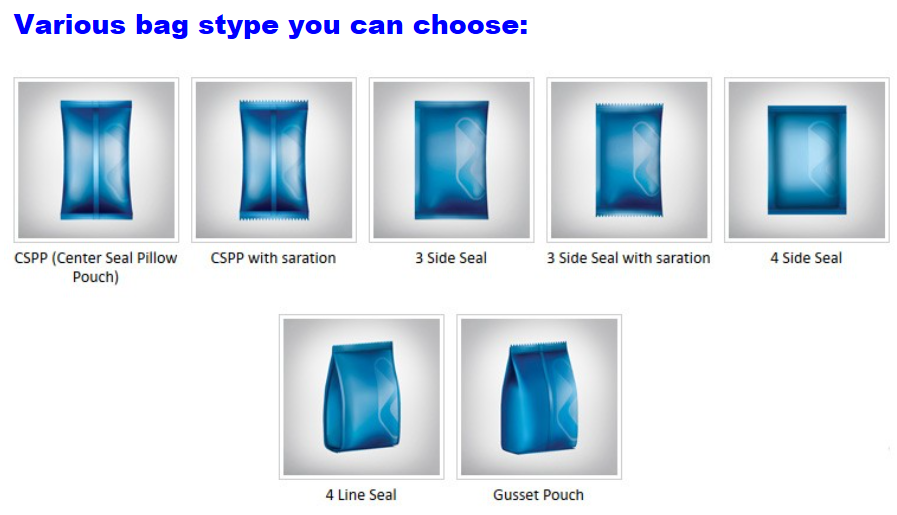

Types of Poly Bags & Different Poly Bags Different Applications

If you choose a poly bag, you need to consider the weight, shape, value, storage, and transportation conditions of the items being packaged, as well as whether you need moisture-proof, dust-proof, or anti-static functions. As the thickness increases, the bag’s protective performance and durability also improve, but the cost will correspondingly increase. Therefore, correctly assessing your needs and selecting the appropriate thickness of the poly bag is crucial.

Polypropylene Poly Bags come in six common thicknesses: 1 mil, 2 mil, 3 mil, 4 mil, 5 mil, and 6 mil. Each thickness is suitable for different scenarios.

1. Common Poly Bag Thicknesses

1 mil (0.001 inches / approx. 0.0254 mm)

Application: Suitable for lightweight, small items with low protection requirements, such as office supplies, clothing, simple retail packaging, and organizing and storing small parts. Due to its thinness, it is low-cost and ideal for disposable or cost-sensitive applications.

2 mil (0.002 inches / approx. 0.0508 mm)

Application: Suitable for slightly heavier items such as books, magazines, non-fragile small appliance parts, and dry food products. It is more durable than 1 mil bags and provides better moisture and protection, suitable for situations that require some strength but not excessive protection.

3 mil (0.003 inches / approx. 0.0762 mm)

Application: Suitable for medium-weight items such as cosmetics, small electronics, and crafts. These bags offer better puncture resistance and some moisture protection, which is ideal for medium protection during transport and storage.

4 mil (0.004 inches / approx. 0.1016 mm)

Application: Suitable for heavy or sharp items such as tools, hardware, construction material samples, and frozen foods. This thickness effectively prevents sharp items from penetrating and provides good moisture and dirt resistance.

5 mil (0.005 inches / approx. 0.127 mm)

Application: Suitable for items requiring a higher level of protection, such as heavy machinery parts, large electronic components, and medical supplies. The 5 mil bags are highly tear and puncture-resistant, making them suitable for long-term storage and transport protection.

6 mil (0.006 inches / approx. 0.1524 mm)

Application: Suitable for packaging under extreme conditions, such as heavy building materials, chemicals, hazardous materials, and moisture-proof packaging for heavy machinery. This thickness provides exceptional strength and durability, capable of withstanding harsh environments to ensure the safety of the contents.

2. Lay-flat Poly Bags, also known chemically as flat polyethylene plastic bags, are bags without side seals or gussets. They remain completely flat when laid out, without any additional three-dimensional shape. Another feature of lay-flat bags is that they are easy to stack and store, saving space, and are convenient for automated packaging processes. They are typically made from transparent or semi-transparent LDPE or LLDPE materials, which have good flexibility, transparency, and moisture resistance.

3. Lay-flat Poly Bags are categorized by thickness (usually measured in mils, with 1 mil equal to 0.001 inches). Different thicknesses meet various packaging needs, ranging from lightweight clothing and stationery to the protection of heavy mechanical parts. They are widely used in industries such as food, retail, and healthcare for packaging, storage, protection, and transportation of items like parts, tools, clothing, food, and documents.

These bags can be sealed in various ways, including zip-top, heat-sealed, or closed with clips or ties, allowing for quick sealing and opening while ensuring the contents remain safe and clean. Lay-Flat Poly Bags have become a versatile and cost-effective solution in the packaging industry.

4. Gusseted Poly Bags are based on standard Lay-Flat Poly Bags but feature added folds or pleats at the bottom or sides. These gussets allow the bag to maintain the flexibility and transparency of LDPE or LLDPE material while increasing its capacity, making it better suited for irregularly shaped or larger items, especially those that need to stand upright. Our vertical form fill seal machines can also produce gusseted bags directly from roll film.

Gusseted Poly Bags are mainly divided into two types:

a. Bottom Gusset: These bags have square or T-shaped folds at the bottom, allowing the bag to stand on its own. They are ideal for filling with powders, granules, liquids, or items that need to be stably displayed upright, such as food, pet food, chemicals, and cleaning products.

b. Side Gusset: These bags have expandable folds on the sides, allowing the bag to expand laterally according to the size of the contents. They are suitable for packaging clothing, textiles, paper, gift baskets, and other flat but bulky items. When not fully filled, these bags can be folded very compactly through horizontal bag packaging machines, saving storage space.

Gusseted poly bags are available in various thicknesses to accommodate products of different weights and protection needs. They can be sealed in different ways, including heat-sealing, zip-top, or open-ended, to suit specific application requirements. This design improves packaging efficiency and enhances product display, making it an ideal choice for many industries, including food, retail, manufacturing, and logistics.

5. Resealable Poly Bags embody environmental awareness.

When you need a packaging solution that keeps items fresh and allows for easy re-opening and resealing, Resealable Poly Bags are the ideal choice. These bags are cleverly designed with a top seal that has a sticky resealable strip. With a gentle press, they seal tightly, and when you need to access the contents, they can be effortlessly reopened and then resealed, ensuring continued freshness or moisture protection.

You can safely store a variety of items in these bags, from delicious snacks and fresh fruits and vegetables to precious stationery and small jewelry pieces. Whether it’s keeping food fresh in the kitchen, organizing and archiving important documents in the office, or carrying personal care items while traveling, Resealable Poly Bags are perfect for various scenarios. Moreover, these bags come in a range of sizes and specifications, from mini sizes to large sizes, to meet your packaging needs for different items.

More importantly, their reusability not only reflects environmental awareness, reducing single-use packaging waste but also means they are more cost-effective. So, next time you’re considering the best way to store and protect your items, consider using Resealable Poly Bags to make your life more organized and tidy.

6. Anti-Static Poly Bags are more suitable for electronic products.

When you have electronic components sensitive to static electricity, precision instruments, or materials susceptible to static electricity, Anti-Static Poly Bags are your reliable assistant in protecting these valuable items. These specially designed bags are made of polyethylene material containing anti-static additives, which can effectively prevent static electricity buildup, reduce the risk of static discharge, and protect the items inside the bag from potential static damage.

When you use Anti-Static Poly Bags, you will find that they not only have the transparency and flexibility of traditional plastic bags but also add an important protective barrier. Whether storing semiconductors, circuit boards, sensitive electronic devices, or transferring components extremely sensitive to static electricity in a clean room environment, these bags can ensure safe transmission and maintain the performance and integrity of the products.

In terms of design, anti-static bags may include three types: the first type has low surface impedance, which can slowly release static electricity; the second type is conductive bags, which can quickly dissipate static electricity; and the third type is metalized film bags, which provide a high level of static shielding effect. Depending on your specific anti-static needs, you can choose the most suitable type.

Moreover, anti-static bags are usually designed with easy-to-identify markings, such as special colors or labels, to facilitate quick differentiation during handling and avoid confusion with non-anti-static packaging. Their sealing methods are also flexible and diverse, ranging from self-sealing strip designs for repeated use to heat sealing for a more secure seal.

7. Bubble Wrap is a classic material in the packaging industry.

As an indispensable helper for packing and protecting valuable or fragile items, Bubble Wrap is a packaging material made of polyethylene film covered with small air cushions or bubbles. Whenever this name is mentioned, many people think of the satisfying “pop” sound, which is one of the unique joys that Bubble Wrap brings.

Whether you need to mail fragile decorations, electronic products, or glassware, or even protect furniture edges when moving, Bubble Wrap provides excellent cushioning. Each bubble effectively absorbs impact and vibration, greatly reducing the risk of damage during transportation. Moreover, its transparency allows you to easily identify the wrapped items, facilitating management and classification.

Bubble Wrap can be used in various ways. You can freely cut it according to the size and shape of the item, then wrap it tightly or layer it for added protection. In the market, Bubble Wrap comes in various specifications, including different bubble sizes and film thicknesses (usually measured in “mil,” with larger numbers indicating thicker film and stronger protective performance), so you can choose the most suitable type according to your actual needs.

In addition to its traditional uses, Bubble Wrap is also creatively used in stress relief toys, games, and even art creation. Some people find that popping the bubbles on Bubble Wrap is a simple yet effective way to release stress and bring immediate relaxation.

8. Mailer Bags

When you need to safely and efficiently mail important documents, clothing, accessories, or e-commerce products, Mailer Bags are your indispensable mailing companion. These specially designed packaging bags are intended for direct mailing through postal or courier services, providing a lightweight, durable, and economical mailing solution.

Mailer Bags are typically made of high-strength composite materials, such as Co-extruded Polyethylene, kraft paper composite film, or environmentally friendly degradable materials, to ensure abrasion resistance and tear resistance during transportation. Sometimes, their outer layer is coated with a waterproof film to prevent damage from rain or snow, ensuring the safe arrival of the mail.

You may find that Mailer Bags are designed with various user-friendly features, such as a self-sealing design with easy-to-peel adhesive strips, allowing you to quickly and conveniently seal the package without the need for tape, while also being easy for the recipient to open. Some styles are also equipped with adjustable self-sealing strips that can be adjusted according to the size of the package, providing a more secure seal.

To further enhance the security and professional image of the mail, Mailer Bags are often printed with a privacy-protective internal coating to prevent others from peeking inside the bag. Meanwhile, the exterior can be custom printed with your brand logo, address information, or return policy, enhancing brand image and facilitating tracking and management.

Whether you are sending single items or processing orders in bulk, Mailer Bags offer a variety of sizes to ensure that each item is properly packaged, reducing the use of filler materials and optimizing transportation efficiency. Therefore, when you want to ensure that mail reaches your customers safely and quickly, choosing a suitable Mailer Bag is undoubtedly a wise and efficient decision.

9. Furniture Bags, as the name suggests, are used for packaging furniture.

When facing the challenges of moving, renovating, or long-term storage of furniture, Furniture Bags will become your reliable assistant in protecting large furniture from dust, scratches, and moisture. These specially designed large plastic bags are designed for sofas, mattresses, chairs, dining tables, and other types of furniture, ensuring they remain clean and intact during handling and storage.

Furniture Bags are typically made of high-strength polyethylene (PE) material, which is not only tough and durable, resisting tearing and abrasion, but also has a certain waterproof performance, effectively isolating moisture and protecting furniture from moisture damage. They come in various sizes to fit different furniture sizes and shapes, ensuring comprehensive coverage and protection.

To use, simply place the furniture carefully into the corresponding size of the protective bag and use the bag’s self-sealing strip or attached sealing rope to seal it tightly, preventing dust and other pollutants from entering. For some large furniture items, some products are designed with openings to facilitate insertion and fixation, ensuring that the bag remains stable and does not slip during movement.

In addition to basic protection, the transparent or semi-transparent material also allows you to identify the internal furniture without removing the bag, making it easy to manage and arrange storage space. For furniture that needs ventilation, some Furniture Bags are also designed with micro-ventilation holes to prevent dust while not completely sealing, avoiding the generation of odors or moisture in furniture during long-term storage.

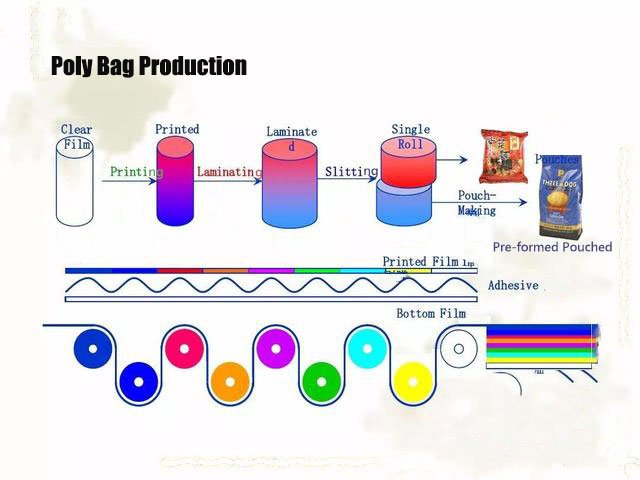

Poly Bag Production

First, you put polyethylene pellets into a mixer and blend them evenly. Then, feed the pellets into an extruder and heat them to 200°C to melt. The plastic tube is gradually cooled as it is extruded. Next, the tube is flattened using a roller to facilitate further processing. The tube is then split open on both sides and cut into the required width with a blade. Excess material is recycled through a pipe for reuse. The cut film is rolled onto a reel. When the film rolled on the reel reaches a certain thickness, workers measure it with a ruler to ensure it is sufficient. Once enough, the film is cut. A fully rolled reel weighs about 158 kilograms and can produce approximately 35,000 regular poly bags.

Next is the printing of the plastic bags. The first step is to keep the ink, which contains alcohol, flowing to maintain its stickiness. The ink roller prints the pattern on the plastic film, followed by another color if needed. After printing is completed, the plastic film is rolled up again and, once the reel is full, it is ready for cutting.

Specialized machines are then used to produce the plastic bags. A sealing machine heats and seals the edges of the plastic bags, and the machine’s wheels place the cut bags onto two shafts. If you want to add a zipper seal to make the familiar ziplock bag, an additional heating step is added to the machine to combine the plastic bag with the zipper seal.

Environmental Impact of Poly Bags

When you pay attention to environmental issues, understanding the impact of Poly Bags (polyethylene plastic bags) on the environment becomes particularly important. Poly Bags, especially single-use thin plastic bags, have a significant impact on the environment due to their widespread use and difficulty in degrading. As a consumer and a citizen of the Earth, it is your duty to protect the planet. For example, carrying reusable shopping bags contributes to reducing this environmental burden.

Plastic Bags VS Poly Bags

When discussing packaging materials, you often come across the terms “Plastic Bags” and “Poly Bags,” which are used interchangeably but have subtle connections and differences.

In fact, “Plastic Bags” is a more general term that refers to all bags made of plastic material, covering various types of plastics, including but not limited to polyethylene, polypropylene, PVC, and others. This term emphasizes the broad category of materials—plastics—rather than a specific type of plastic.

On the other hand, “Poly Bags,” although it appears to be a specific type, in most cases, also refers to polyethylene (Polyethylene) plastic bags. Polyethylene is one of the most common plastics, widely used in the packaging industry due to its flexibility, high transparency, and low cost. Poly Bags typically refer to bags made of LDPE (Low-Density Polyethylene) or LLDPE (Linear Low-Density Polyethylene), which are commonly used in shopping bags, food packaging, clothing packaging, and other applications.

In comparison:

– Material Range: You will understand that Plastic Bags cover all bags made of plastic material, with a more diverse range of types; whereas, Poly Bags specifically refer to plastic bags made of polyethylene, which is a subset of Plastic Bags.

– Application Areas: Both are widely used in daily life, but when you mention Poly Bags, you often think of lightweight, transparent, and flexible polyethylene bags, which are more suitable for packaging light to medium-weight items. The application of Plastic Bags is more extensive, including more durable or specialized properties (such as antistatic, moisture-proof) plastic bags.

– Environmental Considerations: In today’s increasingly environmentally conscious society, both Plastic Bags and Poly Bags face the challenge of reducing usage and increasing recycling rates. Due to the widespread use and difficulty in the degradation of polyethylene plastic bags, Poly Bags have become a point of contention in people’s efforts toward environmental protection and protecting the Earth.

Conclusion

Finding the right packaging bag is key to promoting your brand effectively. A good packaging bag helps customers remember your product, keeps your product in the best condition until it reaches the customer, and can give your brand a unique promotional effect. Once you’ve chosen the right packaging bag, the next step is selecting a packaging machine that can help you pack quickly. For more information, you can click to view “VFFS VS HFFS-How to Choose The Right One for You?”

Of course, if you don’t want to spend time reading again, you can directly click the contact window to contact us. Provide us with your product details, and we will provide you with a packaging solution that meets your needs, solving your problems and saving you time. You will find the ideal polybag for your needs with SembsunPack packaging machines.

Frequently Asked Questions

1.What is the difference between LDPE, HDPE, and LLDPE Poly Bags?

They are all types of poly bags, with the difference lying in the density which determines the bags’ stretchiness.

2. Is a Ziplock bag a poly bag?

Yes, a ziplock bag is a type of polybag with an added zipper seal for easy resealing.

3. Can Poly Bags Be Recycled?

Generally, the poly bags manufactured today are made with recyclability in mind, as part of efforts to protect our planet.

4. Do you Know How Poly Bags Are Recycled?

Recycling plants typically wash, shred, melt, and process recycled plastic bags into various products such as woven bags, soundproofing materials, planting bags, raincoats, and more.

5. Poly Bag Regulations and Standards

The size of plastic bags in our daily lives is usually determined by their purpose, such as food bags, shopping bags, etc. Some countries and regions have regulations specifying the size of plastic bags for different purposes, including maximum size and minimum thickness.

With environmental issues becoming more prominent, some countries and regions are starting to introduce regulations to restrict the use of plastic bags to reduce plastic pollution. Countries are encouraging the use of biodegradable or recyclable bags.

6. Benefits of Poly Bags

Poly bags are ubiquitous in our lives, helping us solve various daily tasks and providing solutions for product transportation and storage for many industries. While they offer many benefits, it’s important to protect and care for our planet, maintaining a healthy relationship with the environment.