Sembsun Vertical Form Fill Seal Machines

- Efficiency: High-speed packaging, reducing labor costs and increasing output.

- Versatility: Can handle a wide range of product types and package sizes.

- Cost-Effective: Uses less packaging material, reducing costs.

- Customization: Allows for various bag styles and printing options.

- Space-Saving: Compact design, suitable for various production environments.

- Hygiene: Ideal for food packaging due to its minimal contact process.

What's the Vertical Form Fill Seal Machines

Vertical Form Fill Seal (VFFS) machines are automated packaging systems used across various industries. They work by forming pouches or bags from a roll of flat film, filling them with a product, and sealing them closed. This process is efficient and continuous, making VFFS machines popular in food processing, pharmaceuticals, and other sectors. This process includes several steps:

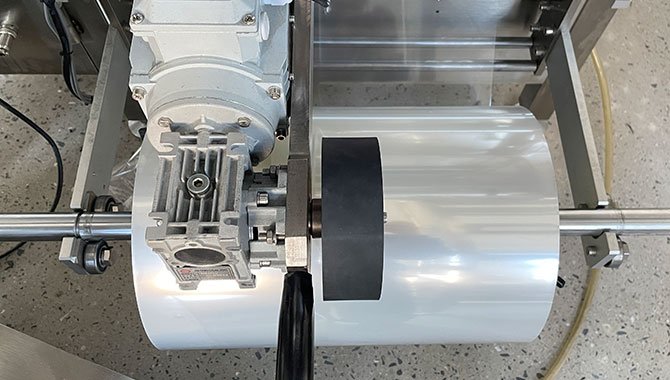

Film Unwinding: The machine unwinds a film roll and forms it into a bag shape.

Filling: The formed bag is filled with the product, be it liquid, granular, or solid.

Sealing: The top of the bag is sealed to close the package.

Cutting: The machine cuts the sealed bag to separate it from the continuous film.

Output: The finished package is then outputted for further processing or packing.

Types of Sembsun Vertical Form Fill Seal Machines

MODEL: D-320, D-420, D-520, D-620, D-720, D-820, D920, D-1200

Suitable for blanking and packaging of liquid, powder, medium, and small particle materials

This packaging machine integrates an efficient 10-14 head combination electronic scale, which can achieve fast and accurate weighing of multi-material proportions. It is suitable for packaging mixed products that require high-precision measurement, such as nuts, candies, puffed foods, etc.

The multi-head combination scale makes the packaging process continuous and smooth and is suitable for large-scale production lines.

This vertical packaging machine is equipped with a pumping system specially designed for liquid materials, which can accurately control the filling amount of liquid and is suitable for packaging liquids of various viscosities. It is suitable for the filling and packaging of various liquid products such as beverages, condiments, cosmetics, medicines, etc., especially where hygienic standards and precise measurement need to be maintained.

Designed specifically for powdery materials, quantitative filling is performed through a special powder pump to avoid powder flying and clogging problems. It is widely used in the packaging of milk powder, coffee powder, seasoning powder, chemical powder, and other products, especially suitable for industries that need to maintain product dryness and purity.

Using a Volumetric Cup Filler, materials complete a series of packaging actions on the turntable, such as forming, filling, sealing, etc., to achieve continuous and efficient packaging operations. It is suitable for rapid packaging of small-sized solid products, such as rice, ice candy, small hardware, etc., and is widely used in food, medicine, electronics, and other industries.

This packaging machine uses linear weighing technology to dynamically weigh materials through a set of linearly arranged sensors to ensure the consistency of the weight of each package. It has strong adaptability and can accurately measure bulk materials of different densities, such as grains, pet food, frozen food, etc. The packaging has high precision and good stability.

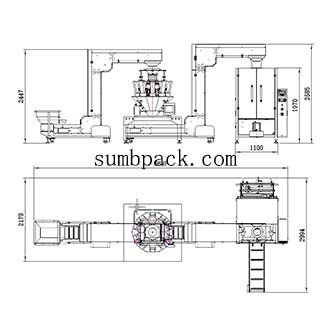

With a Semi-automatic Slope Conveyor, materials are manually put in and lifted to the top by the slope conveyor. It is suitable for packaging multiple products together, it can be packaged according to the manual loading of products, wide applicability. It is suitable for quantitative packaging of granules, powders, and small block products. It is widely used in food, medicine, and other industries to simplify the operation process.

Equipped with 3 vertical packaging machines, 2 machines allow materials to be packaged independently and sent to the third vertical packaging machine through a conveyor belt for collective packaging.

It is often used for independent packaging of coffee powder, soy milk powder, snacks, peanuts and granules.

Using the same 10-head combined electronic scale is suitable for measuring materials. The same measuring equipment is used, which greatly reduces the cost of re-customizing the packaging machine. It is equipped with 2 vertical packaging machines to increase production capacity and meet the needs of customers with high production capacity requirements.

Vertical Form Fill Seal Machine Features

30-60 packages per minute, improving production efficiency.

Seamless heat sealing technology ensures packaging sealing.

Compact design, optimized workshop layout.

Adaptable to a variety of sizes to meet diverse needs.

D-720D Model Vertical Form Fill and Seal Machine for Snacks/Chips/Candy/Liquid

This machine is specially designed for puffed snacks. It adopts an advanced vertical structure to achieve high-speed and precise packaging process. It can automatically complete measuring, bag making, filling, sealing, cutting and other processes to ensure the freshness and sealing of each package of food, improving production efficiency and product appearance appeal.

Vertical Milk Powder Packaging Machine

This equipment is customized for milk powder packaging needs. It is made of stainless steel and complies with food safety standards. Through efficient vertical design, fully automatic operation from bag making to sealing is realized, precise control of milk powder content, strong sealing, effectively extending product shelf life, suitable for milk powder packaging of various specifications, and ensuring product hygiene and quality.

Small Vertical Packaging Machine for White Sugar

This machine is specially designed for small packaging machines of white sugar. Its compact vertical structure saves space. It has automatic weighing, bag-making, filling, and sealing functions to ensure the accuracy and beauty of white sugar packaging. High-speed operation ensures tight sealing, moisture-proof, and dust-proof. It is suitable for retail and household sugar packaging, improving packaging efficiency and market competitiveness.

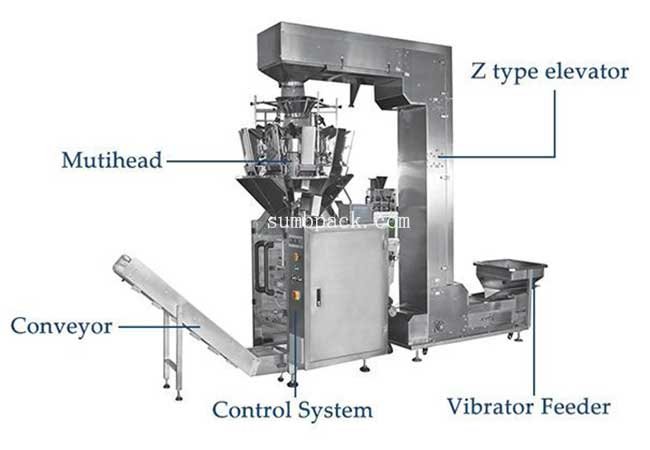

VFFS Ice Packing Machine with Z Type Finished Product Conveyor

Fully automatic ice packing machine, sloped ice loading, 10-head electronic combination scale for weighing. Suitable for crushed ice, tube ice, cubes, edible ice. The packaging film can be composite film or PC film. Greatly improve the efficiency of ice packing.

Mini-Type Vertical Form Fill Seal Machines

MODEL: D-60, D-80, D-160, D-180, D190

Suitable for products with small packaging weight 1g-1000

Suitable for liquid, food packaging, hardware packaging, and medical packaging,

such as puffed food, jelly, sugar, salt, laundry powder, and other granular strips, short strip powder materials packaging.

Compatible Devices

Air compressors are generally used together with nitrogen generators. Its role is to introduce nitrogen into the package by using the pressure difference.

Chain plate conveyor is usually used in packaged products that require stable conveyance and high load – bearing capacity. If your packaged products are bagged products that need to be piled up or transferred in a turning manner, especially in industries with hygiene standards such as food and daily chemicals, this accessory can be added to ensure your packaging automation.

Weight detectors are more commonly used in the food and hardware industries for inspection. In the food industry, especially for vacuum packed cooked food and the proportion of raw materials, it is necessary to check whether they are qualified after packaging. In the hardware industry, small parts such as screws need to be packed according to weight or quantity to ensure that each pack has the same specification.

The ribbon coding machine can give the packaged products their own labels, which is convenient for subsequent search and inspection. Paired with the vertical packaging machine, it is mainly used for vertically packaging products. The ribbon coding is generally printed at the bottom of the bag, and the left – and – right positions can be adjusted according to your requirements. Production and packaging cases can all be used in combination, and are commonly seen in the packaging of puffed foods and medical granules.

When a vertical packaging machine is used for packaging products that require nitrogen, it needs to be paired with a nitrogen generator and a dryer. If your product is an oxygen-sensitive food, such as fried snacks, fresh fruit and vegetable slices, milk powder, coffee powder, seasonings, pet food, etc., nitrogen packaging is important. It is also suitable for packaging fragile foods like fruit and vegetable crisps (such as banana chips), puffed snacks, and thin biscuits. Additionally, it is used for packaging electronic components, precision parts, and pharmaceuticals. The nitrogen environment helps prevent metal parts from oxidizing or pharmaceuticals from absorbing moisture and deteriorating.

The screw feeder is used to transport powder materials. When paired with a vertical packaging machine, it ensures accurate measurement, continuous operation, and a dust-proof design, allowing for efficient and automated packaging of powdered products. Common applications in the food industry include flour, milk powder, seasoning powder, protein powder, and milk tea powder. In the chemical industry, it can be used for dye powders, plastic pellets, flame retardants, paint powders, and metal powders. In the pharmaceutical industry, it is used for traditional Chinese medicine powders, Western medicine raw material powders, probiotics powder, and disinfectant powders. In agriculture, it is used for pesticide powders, fertilizer powders, seed coating powders, and feed additives. In the daily chemicals industry, it includes laundry powder, fabric softener powder, cosmetic powder, and body powder.

We offer screw rods made of 304 and 316 stainless steel to meet the different packaging needs of manufacturers.

The commonly selected Z-type feeding machine requires a factory height of at least 3 meters to ensure smooth operation. Our standard height is 3.8 meters, but we can adjust the height according to the customer’s needs to match the vertical packaging machine.

The vertical packaging machine, when used with a nitrogen generator, effectively stores nitrogen and supplies it to the packaging machine, ensuring a stable working environment.

Specifications

- Application

- Machine Details

- VFFS Data Sheet

- Small VFFS Data Sheet

- Standard Size

Bag Types: Standup Pouch, Ziplock Pouch, Pillow Bag, M Shape Pouch, Side Stand Up Pouch, 4 Sides Sealing Pouch, Ziplock 8 Sides Pouch, Gusset Pouch

| Machine Model | D-320 | D-420 | D-520 | D-620 | D-720 | D-820 | D-920 | D-1200 |

| Max Roll Film Width(mm) | 320 | 420 | 520 | 620 | 720 | 820 | 920 | 1200 |

|---|---|---|---|---|---|---|---|---|

| Bag Width (mm) | 40-150 | 60-200 | 80-250 | 100-300 | 100-350 | 160-400 | 100-450 | 200-580 |

| Bag Length(mm) | 50-200 | 20-300 | 80-380 | 80-450 | 80-470 | 90-500 | 100-580 | 100-600 |

| Power(kw) | 1.5 | 2 | 2.5 | 2.8 | 3.2 | 4.2 | 5.2 | 6.2 |

| Packing Speed(B/M) | 5-60 | 5-55 | 5-55 | 5-50 | 5-50 | 5-45 | 5-40 | 5-30 |

| Power Supply | 220V 50/60HZ | |||||||

Function and Features

1. PLC computer control system, operation is more stable, and can not stop to adjust any parameters.

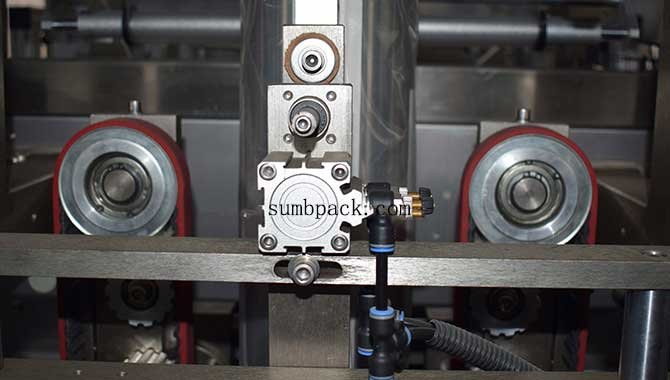

2. Use a servo motor to pull the film, positioning is more accurate.

3. Independent temperature control system, accuracy up to ±1℃.

4. Independent control of transverse and longitudinal sealing temperature, which can better apply to various composite films, PE film, and other packaging materials.

5. Diversified packaging styles, back seal, insert angle, bag, punching, and so on.

6. Bag-making, sealing, packaging, and printing date are completed at one time.

| Machine Model | D-60 | D-80 | D-160 | D-180 | D-190 | |

| Max Roll Film Width(mm) | 200 | 400 | 220/320 | 220/320 | 420 | |

|---|---|---|---|---|---|---|

| Bag Width (mm) | 25-100 | 25-190 | 150/100 | 150/100 | 60-200 | |

| Bag Length(mm) | 200-250 | 200-250 | 50-250 | 50-250 | 60-250 | |

| Measuring Range(ml) | 1-100 | 1-500 | 1-500 | 1-500 | 50-1000 | |

| Packing Speed(B/M) | 5-15 | 5-15 | 5-60 | 5-60 | 5-45 | |

| Machine Weight(kgs) | 150 | 150 | 250 | 250 | 350 | |

| Film Thickness & Property | 400-800 Micron OPP/ CPP , OPP/PE, MST/PE/PET/PE, OPP/CPP | |||||

Function and Features

1. With a compact structure, stable, easy to operate, and convenient to repair.

2. Finish all processes automatically in one machine, from measuring, filling, bag making, bag length chasing cutting, and date-printing to finished productions conveyance by equipped with measuring device, date printer, photocell, etc.

3. Adopt a photo eye control system, stable and practical.

4. This machine is suitable for bag types such as pillow bags, three-sided seals, four-sided seals, triangle bags, etc. Besides, one machine can only make one kind of bag type.

Machine Size Details

| Machine Model | D-320 | D-420 | D-520 | D-620 | D-720 | D-820 | D-920 | D-1200 |

| Machine Size(mm) | 1350*1200*1450 | 1350*1200*1450 | 1500*1140*1540 | 2230*1450*2000 | 2230*1450*2000 | 2500*1600*2200 | 2500*1600*2200 | 2500*1600*2200 |

|---|---|---|---|---|---|---|---|---|

| Machine Weight(kgs) | 350 | 450 | 480 | 560 | 750 | 780 | 850 | 1200 |

There is a limit to the length of the vacuum bags that the vertical packaging machine can evacuate. It is best to confirm the machine model and then ask the customer to send the product. After debugging the machine, the customer can design the roll film.

Yes, but for nitrogen filling, a tube will be partially installed on the bag former to inflate the bag at the bottom, but the amount of inflation cannot be guaranteed.

Can recommend customers universal cup.

Related Product

Customers Generally Ask

Vertical Form Fill Seal (VFFS) is a type of automated packaging technology. It forms packaging pouches from rolls of flat film while simultaneously filling them with product and then sealing them. This method is widely used across various industries due to its versatility and efficiency.

A VFFS machine is an automated packaging system. It creates pouches from a roll of flat film, fills them with a product (like food, liquids, or granules), and then seals them. This process is efficient for high-volume packaging needs.

VFFS machines automate the packaging process, significantly boosting efficiency. They handle high-speed operations, reducing labor costs and time. Their precision and speed make them ideal for industries like food processing and pharmaceuticals.

Absolutely! VFFS machines are incredibly versatile. They can package a wide range of products, from powders and solids to liquids. This makes them suitable for various sectors, including snacks, coffee, pet food, and many others.

VFFS machines offer several customization options. They can create different bag sizes and styles, like pillow bags, gusseted bags, or doypacks. You can also add features like zip locks, tear notches, or unique printing for branding.

These machines are cost-effective due to their efficient use of packaging material and reduced labor costs. They minimize waste and provide consistent packaging quality, which can significantly reduce overall production costs.