Sembsun Automatic Small Vertical Form Fill Seal Machine

- Weighing and Filling Packing

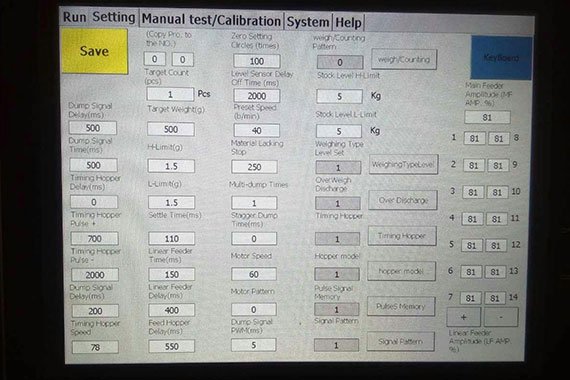

- Microcomputer Control System

- Adjust the Heating Temperature

- Set the Bag Length and Automatically Run the Film

- Suitable for Automatic Packaging of Solid, Powder, and Liquid

Different Between Small Vertical Form Fill Seal Machine and Large Vertical Form Fill Seal Machine

All of them are automatic bag packing machine. First of all, from appearance, the most obvious difference is in their film formers. The large vertical packaging machine is a lapel-style bag former, which looks like a collar. The small vertical packaging machine is a trunk-style bag former that looks like an elephant’s trunk.

Why do we have two types of vertical packaging machines?

The reason is to provide customers with different needs. Generally speaking, the large vertical packaging machine is used by customers who package products with a weight of more than 500g or small packages into large packages. The small vertical packaging machine is mainly used for small bags, which is more flexible and is also suitable for small and medium-sized buyers.

Small Vertical Form Fill Seal Machine For Powder

Packaging Machine Sealing Machine From Bag Making, Measuring, Filling, Sealing, Counting and Date Printing

Vertical type, suitable for 3 sides sealing bag, pillow bag, Filling, Sealing, weighing small powder filling machine

Automatic Powder Bagging Machine in SS304 structure, easy cleaning, suitable for Pillow bag

Complete weighing, feeding, bag making, sealing, cutting and outputting finished products

Featured with a compact structure, suitable for packing powder products like protein, milk powder, flour, coffee powder etc.

Small Vertical Form Fill Seal Machine for Liquid

Mini Liquid Packing Machine with compact design, stable, easy to operate, and convenient to repair.

Sauce packaging machine with U liquid weighing equipment, Heating and stirring liquid products, and precise packaging.

High sensitive photocell on the hopper, high accuracy, Roll film packaging, rounded corners after sealing.

Liquid Pouch Packing Machine -high speed honey stick machine, Packing material in OPP/CPP. OPP/CE. MST/PE/PET/PE

Suitable for three-sided sealed bags, with the smallest footprint, the first choice for small factories.

Small Vertical Form Fill Seal Machine for Solid

Small bags of granules are matched with a turntable for quantitative feeding to reduce errors

Applicable to soybean-sized particles, independent small packaging to avoid waste.

Compared with D-60 model, compact structure, the maximum film width is 400mm, suitable for pillow bag,

The universal cup is suitable for multiple sets of cups, packing white sugar of different grams, suitable for coffee seasoning.

Individually packaged cashews are easy to sell and carry, suitable for packaging in nut production plants.

Small Vertical Form Fill Seal Machine with Bucket Chain Conveyor

Bucket Chain Conveyor and manual loading saves packing machine budget.

Maximum film width 420mm, packaging speed 300-2700 packs per hour.

Maximum film width 220/320mm, packaging speed 300-3600 packs per hour.

Maximum film width 220/320mm, packaging speed 300-3600 packs per hour

Noodles with soup

Suitable for packing small bulk products, such as candy, peanuts, coffee beans, soybeans, corn, and so on.

Small Vertical Form Fill Seal Machine with Vibration Feeder For Hardware

Screw Counting Packaging Machine, which can have automatic feeding, automatic counting, automatic bag making, automatic sealing and cutting, automatic conveying, and automatic detection.

Customized vibration plates are made according to screw and special parts samples, with precise counting and control of division to ensure that each bag is accurate.

The bag former can set the bag length at will on the touch screen, and the feeding is driven by a variable frequency motor, and the running speed can be adjusted at will.

The computing control device adopts spacing counting and fiber rechecking or full fiber counting.

Single variety single disc metering screws, standard screw packaging can be used with multiple vibration discs at the same time.

Our Small VFFS Machine Advantage

Compact Design and Flexible Operation

Quickly Adapt Different Sizes and Shapes

Reduce Energy Consumption

Structure Relatively simple

Automatic 3 Small VFFS Machine Projects with One Conveyor Belt

3 small vertical packing machines with turntables are used to package granular food. The same conveyor belt transports the products to 3 machines for feeding. 3 machines simultaneously pack 3 different packaging bag films, which greatly improves production efficiency and also meets the production scale of the OEM factory. Reducing the number of loading devices for each machine further controls costs. Our factory also supports customized services for different customers.

Small Vertical Packaging Machines Suitable for a Variety of Roll Film Materials

Mainly including:

1. PET/PE composite film: has good mechanical strength and printing adaptability, high transparency, can effectively display products, and has good moisture and oxygen resistance.

2. OPP/CPP composite film: relatively low cost, light and thin texture, suitable for fast packaging, with good heat sealing and printing effects.

3. Aluminum foil composite film (such as PET/AL/PE): increases barrier properties, especially suitable for packaging light and gas-sensitive products, such as coffee, tea, etc., to maintain product freshness and fragrance.

4. Paper/plastic composite film: combines the environmental protection characteristics of paper and the packaging performance of plastic to improve the packaging grade, suitable for products that require higher display effects.

The small vertical machine automatically supplies and forms the film, speeds up the packaging speed, reduces labor costs, and attracts consumers with high-quality printing effects.

Automatic Vibration Cup for Multiple Weights

The Vibration Cup is a standard measuring cup. Customers can tell us which specific weights they need to include, and the cups will be made according to the weights. Each set of Vibration Cups has a weighing range. The set cup is a cup added directly in the middle of the Vibration Cup. It can directly fix a certain weight and cannot be adjusted. If multiple weights are required, a set cup needs to be customized.

Support multiple sealing methods

The packaging machine is very compatible. By adding specific equipment, it can pack simple back-seal bags, zigzag bags, three-side seal bags and four-side seal bags. By adding a perforating device, it can pack back-seal perforated bags. Special bag types also include linked bags, strip bags, and triangle bags.

Sealing method

Packaging Machine Remote Control System

Real-time monitoring and data visualization: The system can collect various operating data of the equipment in real time, such as pressure, temperature, voltage, current, output, etc., and convert these data into intuitive chart information, which is convenient for managers to view anytime and anywhere on mobile phones, computers or tablets, and understand the equipment status and production progress in real time.

Fault maintenance and intelligent scheduling: The remote control system supports remote troubleshooting and software upgrades without the need for on-site engineers, which greatly reduces maintenance costs and time. At the same time, it can integrate operation and maintenance resources, intelligently dispatch maintenance personnel according to the fault situation, and improve maintenance efficiency.

Special Packaging Film Case

There are 2 models of small vertical water-soluble film packaging machines, of which the film width is 100 mm-200 mm, and the maximum can be customized to 240mm. Since water-soluble film is easy to stick, we designed the shaft, accessories, paper feeder, bag maker and mold horizontal and vertical seals to be coated with Teflon. This ensures that the packaging process will not be unable to be packaged due to sticking.

Using a vertical packaging machine with customized roll film is one of the ways to increase brand awareness and quickly integrate into the market.

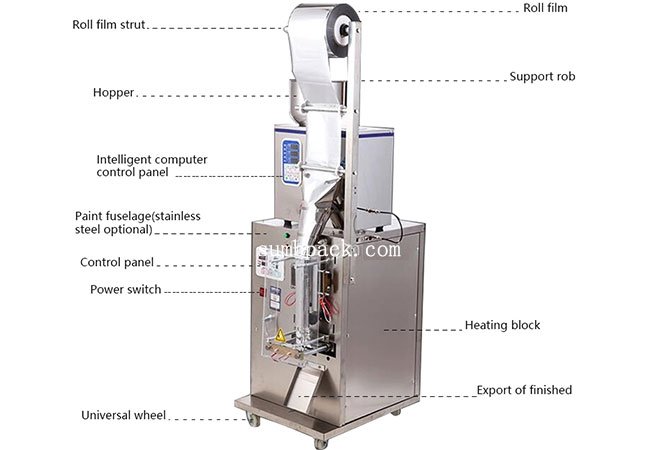

Small Vertical Form Film Seal Machine Details

- Specifications

- Bag Types

| Machine Model | D-60/K/F/Y/B/P3 | D-80/K/F/Y/B/P | D-160/K/F/Y/B/P | D-180/K/F/Y/B/P | D-190/K/F/Y/B/P | |

| Max Roll Film Width(mm) | 200 | 400 | 220/320 | 220/320 | 420 | |

|---|---|---|---|---|---|---|

| Bag Width (mm) | 25-100 | 25-190 | 150/100 | 150/100 | 60-200 | |

| Bag Length(mm) | 200-250 | 200-250 | 50-250 | 50-250 | 60-250 | |

| Measuring Range(ml) | 1-100 | 1-500 | 1-500 | 1-500 | 50-1000 | |

| Packing Speed(B/M) | 5-15 | 5-15 | 5-60 | 5-60 | 5-45 | |

| Machine Weight(kgs) | 150 | 150 | 250 | 250 | 350 | |

| Film Thickness & Property | 400-800 Micron OPP/ CPP , OPP/PE, MST/PE/PET/PE, OPP/CPP | |||||

This machine is suitable for bag types such as pillow bags, three-sided seals, four-sided seals, triangle bags, etc. Besides, one machine can only make one kind of bag type.

Related Product

Small Vertical Packaging Machines Solution

Coffee pouch machine, sachet sealing machine, honey packing machine, powder sachet packing machine, powder sachet filling machine, honey sachet packing machine, sauce pouch packing machine

Yes.

If the small vertical machine 180 machine is equipped with a vertical screw, it can only make back-sealed bags because the three-side sealing former is flat, so it cannot make three-side sealing bags.

A photoelectric eye is installed at the discharge port of the vertical machine. When it detects that there is material falling from the discharge port, it automatically forms bags.

The temperature of a vertical machine coder is most suitable at 120 degrees.

If you need to print two codes on the bag at the same time, you can use two ribbon coding machines.