Sembsun 6-Station Rotary Pouch Packing Machine

Integrated packaging machine with weighing electronic combination and rotating main unit

- Automatic bag opening, unloading, sealing, and coding

- Automatic weighing of products, accurate weight

- Small footprint, complete functions

- Favorable price

Sembsun Rotary Packing Machine 6 Stations VS 8 Stations

The 6-station rotary pouch filling machine is more suitable for small commercial packaging companies, cost-effectiveness, space utilization efficiency, ease of operation, and suitable for companies with medium and low production needs.

1. Cost-effectiveness: The initial investment cost and maintenance cost of the 6-station machine will be lower than that of the 8-station machine due to its relatively simple structure, which is suitable for small enterprises to develop the market in the early stage.

2. Small space occupation: Fewer stations mean that the overall machine may be more compact, which is suitable for production environments with tight space layout.

3. Flexibility to adapt to small batch production: For small enterprises with changing product types and frequent changes in product lines, the flexibility and convenience of adjusting settings of the 6-station machine may be more advantageous, while the 8-station rotary packaging machine has other functions, such as secondary unloading, vacuuming, etc.

4. Energy efficiency: A machine with fewer stations may consume relatively less energy during operation, which is beneficial to saving production costs in the long run.

Configuration

- Rotary Host Machine

- Machine Design

- Packing Parts List

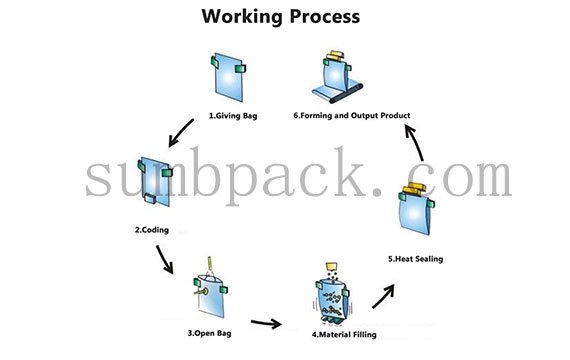

- Packaging Process

- One set of main 6-station rotary packaging machine

- 12-head electronic combination weighing head (0.5L/0.8L/1.0L/1.6L)

- Automatic finished product conveyor belt

Whole packaging process line:

1. Given Bag

2. Coding

3. Open Bag

4. Filling

5. Heat Sealing

6. Forming

Sembsun Automatic Rotary Pouch Packing Machine Parts

6-Station Rotary Pouch Filling

- Stable speed, lower noise

- Horizontal operation, stable servo

- Common screen display, simple and clear

- Stepless speed regulation, cam drive

- Speed can reach 600-4800 bags per hour

12 Heads Combination Weigher

An electronic combination scale measures the weight of ice cubes and multiple heads, and the packaging weight data is more accurate.

Bucket Conveying System with Vibrating Feeder

This conveyor is suitable for vertical lifting of granular materials, such as beef jerky, chicken, candy, dried fruit and other materials. The elevator is driven by a chain to lift the hopper. It is used for vertical transportation of grain or small pieces of materials. It has the advantages of large lifting capacity, lifting height, and lower material breakage rate.

Sembsun Service Term

Technical Data

- Packing Machine Date

- Packing Bag

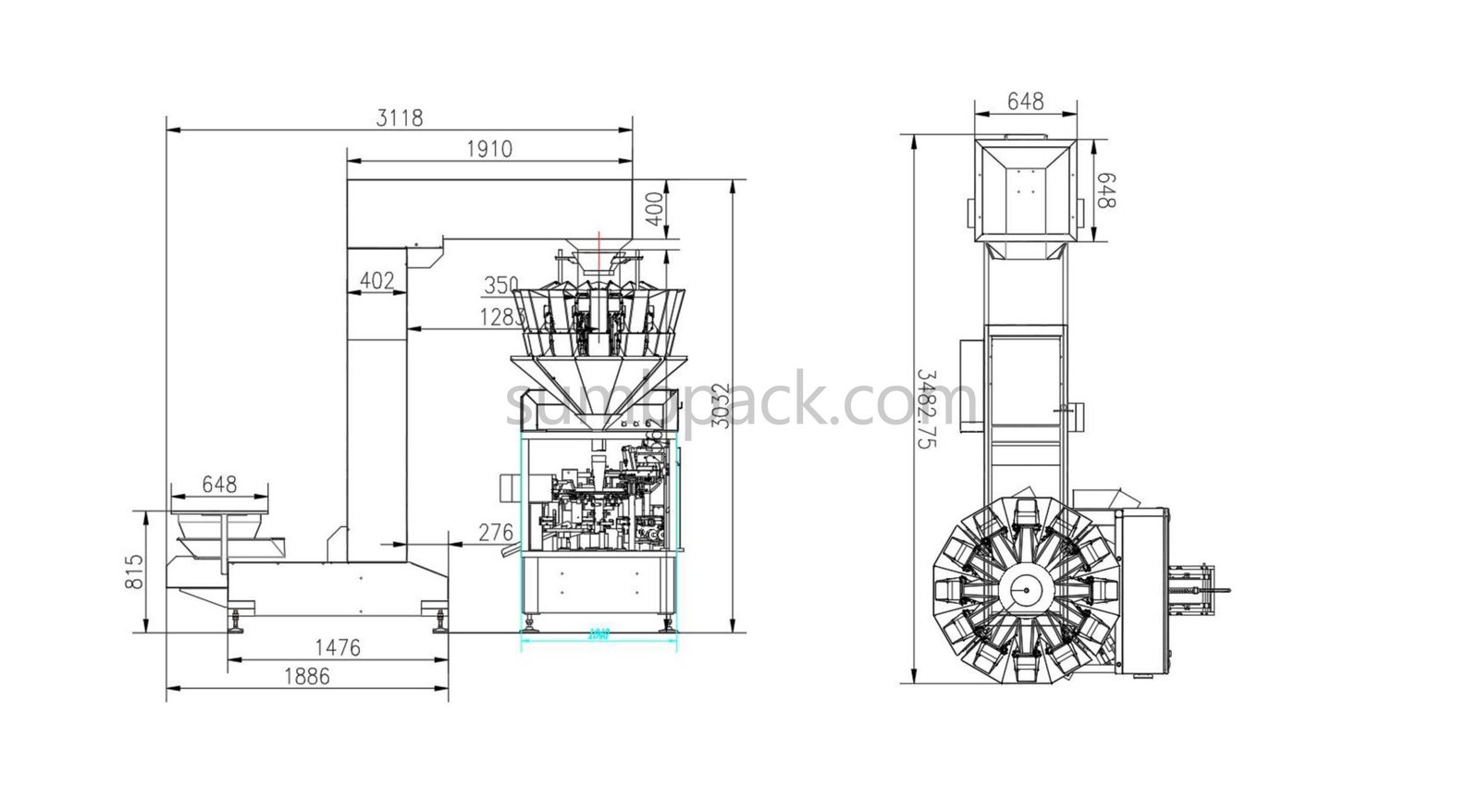

| Model | D-200YT |

| Packing specifications | Length 140-300mm, Width 80-200mm |

| Packing speed | 10-80 bags/minute |

| Power requirements | 380V three-phase five-wire,6.5KW |

| Compressed air | Equipped with vacuum generator: 5-7kg/CM2, 600M3/MIN Equipped with vacuum pump bag opening: 5-7kg/CM2, 300M3/MIN (needs to be external) |

| Dimensions | 1140*1050*3000mm |

| Packing film material | Single-layer PE, PE composite film, paper film, and other composite films |

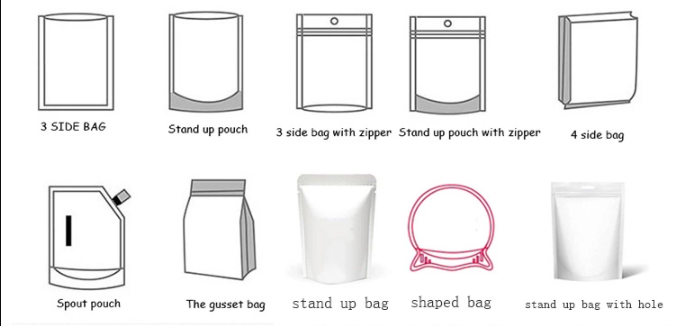

| Optional packaging style | Flat bag, self-supporting bag, zipper bag, handbag, M bag (equipment needs to be partially modified)

|

| Weight | 1500KG |

Related Machine Model

Application

It can be equipped with a liquid pump or a powder feeding device. We can match the device to your material.

Since the hot glue is blocked at the seal, you can use a ball of steel wool to clean the machine seal.

Yes, you can send us the size of your self-supporting bag with a mouth, and we will provide you with a solution