Sembsun Automatic Shrink Wrap Machines

- Efficiency: High-speed packaging, reducing labor costs and increasing output.

- Versatility: Can handle a wide range of product types and package sizes.

- Cost-Effective: Uses less packaging material, reducing costs.

- Customization: Allows for various bag styles and printing options.

- Space-Saving: Compact design, suitable for various production environments.

- Hygiene: Ideal for food packaging due to its minimal contact process.

What's the Automatic Shrink Wrap Machines

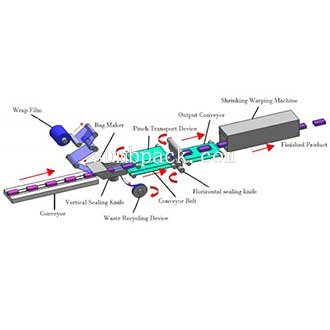

It is composed of an Automatic Flow Wrap Packaging Machine and a Heat Shrink Tunnel.

A: The Heat Shrink Wrap Equipment consists of two parts:

The First Part (the left of the picture ): Sealing and Cutting part

The types of sealing and cutting parts include Flow Wrapping Packaging Machine, Shrink Bundling Machine, L Sealing Machine, (small) Edge Sealing Machine, and Double Edge Sealing Machine.

The Second Part (the right of the picture ): Heat Shrink Tunnel Part

1. This machine combines foreign advanced shrinkage and air transport technology and is continuously improved and uniquely designed and manufactured. The hot air is even and the shrinkage effect is excellent.

2. This machine is suitable for shrink films of various specifications such as PVC, OPP, POF and so on.

3. The main electrical components such as switches, temperature control, and speed regulation are all made of high-quality components, with stable operation and low failure rate.

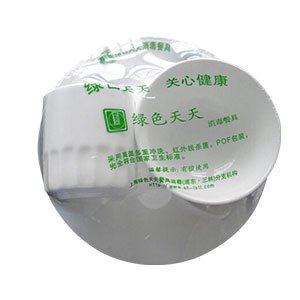

4. The packaged products have the functions of beautiful appearance, dust-proof, moisture-proof, damage-proof and fresh-keeping, which greatly reduces product loss.

Types of Sembsun Shrink Packaging Machine

1. 590 Series Type Flow Wrapping Heat Shrink Packaging Machine

2. Shrink Bundling Machine

3. Automatic L Sealers Heat Shrink Packaging Machine

4. Side Sealing Machine with Heat Shrinking Film Packing Machine

5. Heat Shrink Tunnels

Three servo control, mechanical structure, easy maintenance. The packaging speed and bag length are servo-controlled, with step-less speed change and a wide adjustment range, which can match the front process of the production line. Suitable for the food industry, pharmaceutical industry, toys, and stationery, plastic products, industrial products, daily necessities, disposable products, hardware products, industrial parts, auto parts

It combines heat shrink technology and the working principle of continuous rotation to provide efficient, beautiful, and economical packaging solutions. It is used in dairy beverage industry packaging, food convenience food packaging, daily chemical products, electronic products, industrial products packaging, pharmaceutical frozen food packaging, and automatic feeding large packaging lines.

The operating principle is based on a reciprocating conveying system that can accurately deliver the product to the designated location and then wrap the product with pre-cut heat shrink film. It is widely used in many industries such as food, beverages, medicines, cosmetics, electronic products, and printed materials. It not only improves production efficiency but also protects the safety and hygiene of products during transportation and sales.

With a flow wrap type machine and a heat-shrink furnace. This series of 590-type heat shrink film machines is equipped with waste recycling devices, which can save the waste of rolled films. 2 ways of Back Sealing:

Electrostatic Adsorption: (similar to the AB longitudinal sealing method of vertical machines) – you can judge whether it can be sealed based on the customer’s product box film

Cut Edge Sealing: The most common sealing method.

The maximum film width of this machine is 820, which is a larger packaging machine than 590 and has a faster packaging speed. The product is tightly wrapped with plastic film, and then heat is used to shrink it, which is both dust-proof and beautiful. The film material is rotated and wrapped, and then heated after sealing. It is suitable for product packaging in many industries such as food, beverages, printed materials, and daily necessities.

Sealing method: Both sides are left unsealed, similar to a sleeve, not fully wrapped. Most commonly seen in beverage and mineral water packaging, suitable for taller products. Height and width are adjustable, with no strict limitations. Characteristics of film used: Generally made of PE film, known for its good toughness and load-bearing capacity. Usually single-layered, but the film rolls come in a dual-roll structure, one on top and one on the bottom.

The machine adopts foreign advanced technology so that the process of product packaging can be accurate and stable. It has the function of automatically collecting, stacking, wrapping film, dissolving, and body-fitting heat-shrinkable packaging for a single package. The products packed by this machine are intuitive, convenient to transport, and low in cost. It is widely used in medicine, food, beverage, cultural goods, daily necessities, cosmetics, hardware tools, electronic products, and other items of packaging.

Sleeve equipment is a machine that uses PE film as shrink film. Common products include outer packaging of soda trays, secondary packaging of beverages, etc. that require thickness requirements.

Sembsun Side Sealer Machines

This machine can automatically collect, stack, wrap, weld, and shrink the single-piece packaging at one time.

Applicable shrink film: POF.PE

Width calculation formula = product width through the machine mm + height mm + 150mm

Maximum packaging size: Length L+Height H: ≤400

Maximum packaging size: Width W+H: ≤300mm

Sealing knife size: L*W(mm): 570×470

Machine size: Length*Width*Height(mm): 1700x830x1450mm

Maximum packaging size Vertical length L+height H: ≤500

Maximum packaging size Horizontal width W+H: ≤400mm

Sealing knife size L*W(mm): 670×570

Machine size Length*width*height(mm): 1900x930x1450mm

Maximum packaging size Vertical length L+height H: ≤600

Maximum packaging size Horizontal width W+H: ≤500mm

Sealing knife size L*W(mm): 770*670

Machine size Length*width*height(mm): 2100*1030*1450

Maximum packaging size Vertical length L+height H: ≤700

Maximum packaging size Horizontal width W+H: ≤600mm

Sealing knife size L*W(mm): 870*770

Machine size Length*width*height(mm): 2300*1130*1450

Maximum packaging size Length L & Height H: Length unlimited & Height ≤ 150mm

Maximum packaging size Horizontal width W+h: ≤300mm

Sealing knife size L*W (horizontal): Length unlimited * Width 470

Machine size Length * Width * Height (mm): 1700*975*1440mm

Maximum packaging size Height H: Length unlimited & Height ≤250mm

Maximum packaging size Horizontal width W+h: ≤400mm

Sealing knife size L*W (horizontal): Length unlimited * Width 570

Machine size Length * Width * Height (mm): 1900*1075*1540mm

Maximum packaging size Height H: ≤300

Maximum packaging size Horizontal width W+h: ≤500mm

Sealing knife size L*W (horizontal): Length unlimited * Width 670

Machine size Length*width*height(mm):2100*1175*1540

Maximum packaging size Height H: ≤300

Maximum packaging size Horizontal width W+h: ≤600mm

Sealing knife size L*W (horizontal): Length unlimited*width 770

Machine size Length*width*height (mm): 2300*1275*1590mm

Sembsun Heat Shrink Tunnel

The shrink tunnel heater is an essential equipment for the automatic shrink wrap machine. Different sizes of products with different shrink tunnel heaters will make your packaging process more efficient.

Dual Frequency Conversion,It allows independent adjustment of the speed of the conveyor belt and hot air circulation system to achieve energy saving and emission reduction effects.

Product size Width * Height (mm): 200*100

Conveying speed: 0-15 meters/minute

Product size Width * Height (mm): 200*100

Conveying speed: 0-15 meters/minute

Product size Width * Height (mm): 300*150

Conveying speed: 0-15 meters/minute

Product size Width * Height (mm): 350*150

Conveying speed: 0-15 meters/minute

Product size Width * Height (mm): 400*150

Conveying speed: 0-15 meters/minute

Product size Width * Height (mm): 400*250

Conveying speed: 0-15 meters/minute

Product size Width * Height (mm): 550*300

Conveying speed: 0-15 meters/minute

Why Choose Full Automatic Shrink Packing Machine

Including feeding, sealing, cutting, and heat shrinking.

Equipped with a user-friendly operation interface.

Food, Beverages, Daily Necessities or Electronic Products.

Forming a Perfect Transparent,Moisture-proof.

590 Heat Shrink Packaging Machine for Carton

The heating shrink film oven uses advanced infrared or hot air heating technology, which can quickly and evenly heat the shrink film, ensuring that the packaging film fits closely to the contour of the product, forming a smooth and tight wrapping effect, which not only enhances the visual appeal of the product, but also enhances the protectiveness of the packaging, and is moisture-proof, dust-proof and wear-resistant.

Shrink Bundling Machine for Bottled Water, Carbonated Drinks

This combination machine is particularly suitable for products with irregular shapes or that require three-dimensional packaging, such as boxed food, cosmetics, daily necessities, etc. The pillow packaging machine can automatically adjust according to the product size, while the heating shrink film oven can adjust the heating intensity according to the film material, which together ensures good adaptability to diverse products.

L-Sealers Heat Shrink Packaging Machine

1. Sealing method:

There are two side sealing knives on the side, and the height position of the entire horizontal and side sealing can be adjusted up and down. Packaging with regularly shaped products looks more aesthetically pleasing because the sealing and cutting position can be adjusted to the middle, which cannot be achieved by L-shaped sealing machines. The side sealing machine is more stable, with knives that open and close vertically, and it can package products up to 600mm tall.

2. Characteristics of the film used: PE or POF film is used, with a folded double-layer film or a single roll film.

3. The side sealing machine has two modes: solid mode and hollow mode. It can package two products into one bag for heat shrinkage. Just switch to hollow mode and set a fixed length cut to package two products into one bag.

4. The edge sealing machine is equipped with photoelectric eyes that can identify materials and can directly place the materials on the conveyor belt. The machine will automatically separate into 2 products or 3 products per bag according to the settings.

Film Materials

The film materials commonly used are PE and POF films (among which cross-linked films are a common type of POF film), with a thickness of about 3 microns. The most common POF film is the layer of film wrapped around newly purchased mobile phone boxes.

PE film is more resilient and can bear more weight compared to POF, so sleeve-type machines used for packaging mineral water typically use PE film (about 8 microns thick, which becomes harder after heat shrinking and can reach about 10 microns).

PVC film: This type of film is cheaper but toxic, unsuitable for packaging food, and rarely used in industry nowadays. It cannot be used on heat shrink film machines

Specifications

- Machine Details

- Application

- Data Sheet

- Standard Size

| Machine Model | D-450/99 | D-450/120 | D-590/120 | D-590/150 | D-590/180 | D-690/180 |

| Max Roll Film Width(mm) | 450 | 450 | 590 | 590 | 590 | 690 |

|---|---|---|---|---|---|---|

| Bag Width (mm) | 10-150 | 10-150 | 30-200 | 30-200 | 30-200 | 30-250 |

| Bag Length(mm) | 90-400 | 90-400 | 90-400 | 90-400 | 90-400 | 90-500 |

| Bag Height(mm) | 5-40 | 15-60 | 30-90 | 15-60 | 30-120 | 40-120 |

| Packing Speed(B/M) | 50-150 | 50-150 | 50-150 | 50-150 | 50-150 | 50-150 |

| Power(kw) | Packing machine 3.5kwkg,Shrink Tunnel 15kw | |||||

| Power Supply | Packing machine 220V 50/60HZ,Shrink Tunnel 380V 50hz | |||||

Machine Size Details

| Machine Model | D-450/99 | D-450/120 | D-590/120 | D-590/150 | D-590/180 | D-690/180 |

| Machine Size(mm) | 5000×965×1750 | 5000×965×1750 | 5000×965×1750 | 5000×1105×1750 | 5000×1105×1750 | 5000×1205×1750 |

|---|---|---|---|---|---|---|

| Machine Weight(kgs) | 350 | 450 | 480 | 560 | 750 | 780 |

250 ml is usually packed with 24 bottles

1000 ml is usually packed with 6 or 12 bottles

1500 ml is usually packed with 6 bottles

No.

You can use low-temperature film so that the product will not melt, like chocolate.

Related Product

Customers Generally Ask

The photoelectric eye can identify the material, and the material can be placed directly on the conveyor belt. The machine will automatically separate it into 2 products or 3 products per bag according to the settings.

The Side Seal Heat Shrink Packing Machine can add a pusher device to arrange the materials in order.