Improving Quality of Life – RTE Food Packaging Solutions

What is RTE packaging?

RTE packaging means ready-to-eat (RTE) packaging, which is a very common way of handling food products in modern life, providing convenience and efficiency in your life. It follows strict national food safety regulations and meets the needs of everyday human life. There are some related phrases derived from RTE, such as RTS, which means ready-to-serve packaging, and RTC, which means ready-to-cook packaging, which are both related to pre-packaging.

Benefits of RTE Food Packaging

- Time-saving: You can integrate your daily life into it, and you will find that pre-prepared food greatly saves cooking time, and consumers can enjoy it by simply heating or cooking, without the need for tedious preparation of ingredients and complicated cooking process, which is very suitable for busy office workers and people who are not good at cooking.

- A wide variety of dishes: You can choose any pre-made dishes, with a wide variety of varieties covering a wide range of cuisines and flavors, to meet the dietary preferences of different consumers and the need to explore the freshness of the demand. For example, Thai-flavored sour soup noodle, curry-flavored bibimbap, tuna rice, spaghetti with meat sauce, semi-finished French fries, semi-finished fried food, etc. are all popular among consumers.

- Standardized quality control: Prepared food producers unify the production process and quantify the production. Under quality control, the taste and nutrition of each prepared dish are basically the same.

- Reduce food waste: Consumers can buy more of their own actual situation of the size of the portion of prepared food, to avoid wasting food.

- Economical: The emergence of pre-prepared vegetables is proposed and produced at a more economical price. After the producer mass-produces, it also reduces the unit cost price, which also reduces the cost of consumers compared to fast food and takeout.

- Easy to store: Many prepared dishes contain semi-finished and heated products, which need to be preserved using low-temperature freezing or refrigeration techniques, which extends the shelf life of the food. It also facilitates home and commercial stocking programs and is suitable for consumers who live far away from their purchasing address. rte packaging is also extremely important, as it is the correct way of packaging that makes RTE transportation easy.

Who benefits from the RTE Food Packaging Machine

The rise of the ready-to-eat packaging industry has opened up a wide range of business opportunities for upstream and downstream companies involved in food production, logistics, distribution, packaging, agriculture and food safety technology. What are your common employment opportunities? Why don’t you take a look at the following introduction?

- Food producers and processors: The main source of prepared dishes. One of the most important jobs directly involved in the research, development, production and distribution of prepared dishes, through the team’s taste buds to develop dishes, coupled with the scale of production, to meet market demand, expand sales channels, also provide employment opportunities for research and development of the R & D division.

RTE food producers – Four key points you have to consider when developing the products

Food safety: Use strict ingredients, comply with hygienic standards in the production environment, and require strict requirements for food contact machinery and regular disinfection and cleaning of the production plant.

Taste: Developing multi-flavor prepared dishes to provide variety to the market.

Shelf life: extends the shelf life of food by slowing down oxidation through low-temperature treatment.

Retort: Provide consumers with cooking methods to avoid wrong cooking methods affecting the taste of prepared food.

- Cold chain logistics and express delivery: Freshness preservation is one of the keys for prepared dishes to be able to be transported over long distances and stored well. Cold chain logistics companies do a good job of fast delivery while ensuring food safety, and the courier industry has expanded the recruitment of couriers to increase jobs.

- Retail and e-commerce platforms: Retail and e-commerce have become essential marketing methods for joining the market quickly. As a new product, consumers are more willing to try to start, and repurchase as a supplement, so retailers, and convenience stores to drive the market’s share of fast-selling, the recent popularity of this year’s live band has also become one of the efficient ways of sales of prepared dishes. Correspondingly, the positions of salespersons and anchors have also increased to meet the changes in the market.

- Packaging material suppliers: After the mass production of prepared dishes, proper packaging is needed to enhance brand awareness and maintain the taste of the original dishes. Usually, the packaging of pre-prepared dishes is packed in bags, extra bags with trays, boxes with vacuum treatment, cling film, microblogging safety boxes, and other packaging materials, which usher in business opportunities for the respective companies. Better design appearance, better functionality embodied will be favored by food manufacturers. In order to improve the packaging of automated procedures, many businesses also use automated packaging machines to pack products, experimental data show that artificial packaging products exist in the efficiency of the drop, sealing firm and other issues, and packaging machines can be in the rigorous packaging process to pack products, reject failed products, to do the second test, in order to improve the quality of the packaging faster, so the purchase of a packaging machine for the medium and high product business Is essential, only you adapt to the speed of society, you will be able to get more profits.

- Agro-technology and raw material suppliers: Nowadays, the topic of health surrounds people, so the rapid development of the prepared vegetable industry also has requirements for high-quality raw materials, which helps upstream agribusiness and raw material suppliers to optimize the supply chain and expand the cultivation of raw materials.

Food safety testing and technical service providers: food safety is an aspect that consumers have always attached importance to, so the manufacturing of prepared dishes also needs to be tested, for food safety testing, traceability system construction and other related technical services companies will get more opportunities for cooperation!

- Food safety testing and technical service providers: food safety is an aspect that consumers have always attached importance to, so the prefabricated dishes need to be tested after manufacturing, for food safety testing, traceability system construction, and other related technical services for the enterprise will get more opportunities for cooperation.

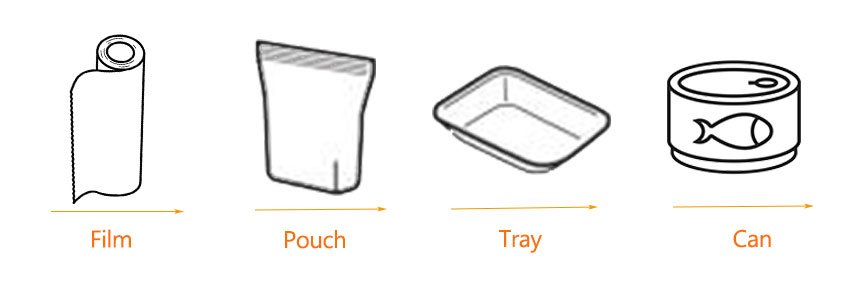

Types of RTE Food Packaging

Film: Film is generally wrapped in a film for the outside of the already packed prefabricated dishes, beautiful and clean, generally use side seal machine and heat shrink wrap machine.

Pouch: Premade pouches have a strong seal and a good-looking design that will attract the consumer’s eye, and premade pouches use a premade pouch packing machine.

Tray: Tray let contain liquid solid prefabricated dishes a fixed position, more beautiful and neat, the cost should be relatively high, the use of cling film packaging machine.

Can: Cans tightly sealed lid, plus aluminum material, so that food is not easy to deform, avoid direct sunlight, filling machine under the material, can sealing machine sealing.

Process of RTE Food Packaging Video

There are two ways of weighing the prepared dishes, one is to weigh them manually and then use the packaging machine to vacuum the prepared dishes and then seal them, and the other is to weigh them by means of an electronic combination and then enter the sealing.

FAQ

- Do I need to freeze or refrigerate prepared dish food?

Usually, it is recommended to keep the food refrigerated. Freezing is for thawing the prepared food.

- Does the packaging benefit from MAP (modified atmosphere packaging)?

The packaging industry does benefit from the application of MAP technology, especially in the packaging of perishable foods such as fresh produce, prepared foods, dairy products and meats, where shelf life can be extended to maintain food quality, reduce the use of preservatives and enhance product appearance. MAP indirectly reduces food waste, and may reduce the need for repackaging of food products due to rapid deterioration, which is good for the environment.

- What type of labeling and marketing is needed for the RTE food container?

Choosing the right labeling and marketing strategy is especially important to ensure transparency of food safety information, attract consumer attention and enhance brand image. Information such as nutrition facts, list of ingredients, date of production and shelf life, manufacturer information, serving suggestion or recipe recommendation, QR code link, etc. can be added. Combine with marketing strategies to promote prepared dishes.