VFFS Machine For Whey Protein Powder Filling

- A film reel auto-alignment shaft

- One set of bottom/horizontal seal Unit

- One set of vertical seal unit

- An independent bag former

- Double belts controlled by double servo-motor pulley

- Pneumatic horizontal/end sealing jaw

- Automatic material-level control system

- Types of Bag

- D-320F Technical Data

- Auger Filler for Wighing Powder

Types of Pouch: Pillow, Hole Punched Pillow Bag, Gusset Standup Bag, Hole Punch Standup Bag, Side Sealing Standup Bag, Chain Bag, etc.

| Items | D-320F |

| Volume | 100ml-1000ml |

| Capacity | 5-70 bag/min‚ |

| Bag size | (L)50-200mm (W)40-150mmƒ |

| Bag type | Pillow-type bag, standing-bevel bag, punch bag |

| Max film width | Max 320mm |

| Film thickness | 0.04-0.08mm |

| Air consumption | 0.8Mps 0.25m3/min |

| Main power/voltage | 2.4KW/ 200V 50Hz |

| Dimension | L1350×W1200×H1450mm |

| Weight | 350kg |

| Item | Auger filler |

| Filling range | 50-1000g |

| Capacity | Max50bags/min |

| Accuracy | ±0.3-1.5% |

| Power | 380V 2.5KW |

| Auger filler dimension | L690*W1030*H1100mm |

| Auger filler dimension | 150kg |

| Measure | Screw rotary filling |

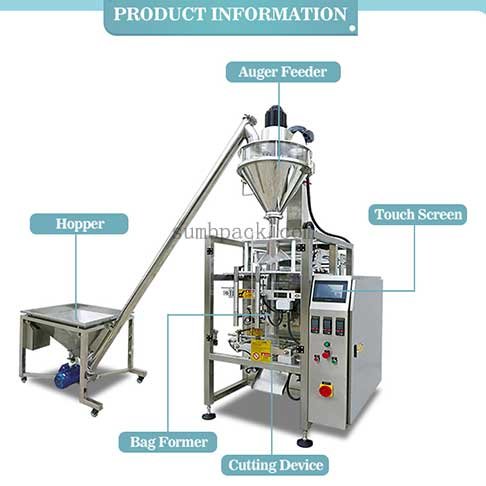

Vertical Form Fill Seal Packing Mahcine for Whey Protein Powder Filling

Vertical Form Fill and Seal Packaging Machines for protein powder are fully automatic machines that come with filling, unloading bag completion, and sealing. Equipped with an auger powder filling machine weigher, the material can be discharged with precise weight. In addition to packaging protein powder, it can also package spices, seasonings, milk powder, milk tea powder, coffee powder, sugar powder, and some powder products.

VFFS Packing Machine for Tea

Suitable for tea leaves of various shapes and particle sizes, such as bar tea, broken tea, scented tea, etc.

It can be made into a variety of bag types, such as back-sealed bags, four-side-sealed bags, triangular three-dimensional bags, etc., to enhance the product’s appearance.

Other Packing Machine Related Products

Vertical Form Fill Seal Packaging Machines for Powder

Accurate metering and efficient packaging create a perfect seal for your powder products. The powder auger filler vertical form fill seal packaging machine upgrades the quality and doubles the efficiency!

1. An accurate and simple design for the film-pulling frame can make the film pull more smoothly and simplify film loading. And the whole set of frames is made of one whole stainless steel cut by laser with high uniformity proportion to make it more balanced, strong, and steady standing on the ground. (But other company normally connects the separate frame parts together to make the whole frame. It will make it with uneven proportion and reduce the strength of the whole set of machines.) The stainless steel sheet thickness is 8mm to make the film run more smoothly and steadily (another company adopts only 5-6mm thickness)

2. The film-discharging motor adopts a braking function and we also fit the pulling belts with a thickness of 23mm(Other company normally uses belts with a thickness of 18mm only) to avoid running out of film during work, we can control the film-discharging motor automatically to adjust the film running direction to the right or left to find out a more proper way by touch screen—this is more humanity; We use undependable air switch to control film-discharging motor, film direction-adjustment motor, and film-pulling motor in which is accord strictly to the rule of the safety of European Standard.

3. Adopt a double belt pulling system controlled by one servo motor with more uniformity running and stable function. The belt has with thickness of 23mm to increase the touch area of the belt and film, in order to make the film run more stable and the finished bags are all in good shape and unfolded. But other companies’ belts are usually with a thickness of 18mm only to save their cost.

- Product details

- Bag width, bag length

- Bag shape

- Packing film material

- Machine frame

Optional Device:

1. Double Film Pulling Device

2. Angle of plug-in Device

3. Automatic Correct Device

4. Linking Bags Device

5. Punching Device

- This machine is suitable for sticky & hygroscopic powders like fruit powder, flour, coffee, milk powder, spray-dried detergent powder, custard powder, glucose powder, bean powder, spices, Henna powder, protein powder, baking powder, water chestnut starch, and other powder in center seal pouches, etc.

- Various bag types are available,e.g. pouch, back-sealing bag, linking bags, etc.

We use adequate material for producing our machines. The whole set of stainless steel frames for the machine is with a thickness of 8mm to make the whole set of machines more strong and steady on the ground. Even during the vibration of running the machine, it will not influence much about the weighing accuracy and film pulling.