What is Packaging Machine ?

The packaging machine is an automated machine that helps humans pack and organize the products that have been produced for the second time, to facilitate sales.

With the continuous evolution of the times, people’s requirements for packaging are constantly improving, and the reform and upgrading of packaging machinery are changing accordingly. Own a fully automatic packaging machine to automatically package your products so that they can be sold to farther places. Tight packaging makes the product beautiful, but more importantly, it can extend the storage time and prevent oxidation.

Packaging Machine By Types

Different types of packaging machines will package different packaging products.

Machine Feature Box

The operation interface is Clear and Easy to Use

No oxidation, easy to clean and maintain

The program is written, no need to re-write.

Wide application and strong adaptability.

Iron Fluorosaurus Function

Iron Floson (Polytesterafluoro, PTFE) In the packaging machine accessory, due to its non-viscosity, it can ensure that the material will not be adhered to the tablet or conveyor belt, thereby ensuring the accuracy and consistency of the measurement. Reduced material residues and made the cleaning work simple and fast. Iron fluorine can resist the erosion of most chemicals, including acid-base solutions. Iron fluorine dragon coating can withstand high working temperatures, and can remain stable even in continuous high-temperature environments. Its material is green and environmentally friendly, which is harmless to the human body. It is suitable for packaging equipment that directly contacts food, which meets food safety standards.

Open Bag Function

The packaging machine contains the bag opening device, especially the opening of the bag in the bag-type packaging machine, which greatly improves full automation. It does not require manual intervention, automatically completes the opening of the bag, and improves the production efficiency box to reduce the cost of labor. Secondly, accurately open the premade pouch bag to ensure that the position of Meisi opening the bag is consistent, and ensure accurate positioning when feeding. It is usually equipped with user -friendly man-machine interface (HMI) so that operators can easily set parameters. At the same time, it reduces artificial contact, reduces the risk of pollution of sensitive products such as food and medicines, and meets strict sanitary standards.

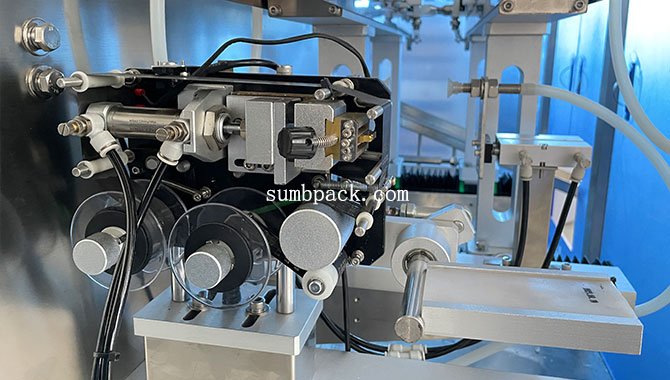

Code Function Part

It can print the information you need in the outer packaging (such as plastic bags, plastic film, cartons, metal cans, etc.), such as printing production date, validity, batch number, serial number, barcode, QR code, product information, warning signs, etc. Necessary information. Through the batch information of printing, the product traces of products from production to consumption, which is convenient for quality management and market monitoring. It helps to prevent counterfeiting and inferiority and protects the rights of brands and consumers.

Among them, modern coding technology (such as laser coding, hot transfer, inkjet printing, etc.) can ensure that the printing information is clear and long-lasting, and it is not easy to erase or tamper.

Customized Packaging Bag Roll Stock Film Advantage

We can provide customized curl (roll stock film)designs for packaging machines purchased in our factory. You can customize the design according to the specific needs of customers, including color, pattern, brand logo, etc. Because we understand the requirements of our packaging machine on the curl film, we can provide your product with more suitable packaging curl film.

You can choose appropriate materials according to product characteristics, such as OPP, CPE, PC, PVC, PP, PA/PE, PET/CPP, PET/PE, etc., as well as aluminum foil composite materials to ensure the protection of packaging, such Fresh preservation and so on. You can increase special functions according to product demand, such as easy tearing threads, breathable holes, hanging holes, sealing, anti-counterfeiting signs, etc. to enhance the user experience.

At the same time, because the curled film produced by the machine is not within range, the custom curl film is produced as required, and we should be closer to the customer’s demand as much as possible. Cross-membrane avoids the storage space requirements of prefabricated bag packaging, and it is more flexible to respond to changes in market demand.

Provide Free Services

The huge prefabricated bag design library can almost meet the personalized needs and preferences of all customers. A large number of design drawings can also be used as a valuable resource for market feedback.

Through the analysis of customers, companies can understand the market trend, adjust the product line in time, optimize the optimization, optimize the optimization in time, and optimize the optimization Design to better meet market demand. Bring a time-saving and labor-saving packaging solution for customers.

Providing free packaging machine CAD (Computer-Aided Design, Computer Auxiliary Design) diagrams directly reduces customers’ early investment costs. Secondly, customers can quickly understand the structure, size, and working principles of the packaging machine by viewing the detailed CAD drawings, and accelerate whether they meet the production needs, so as to make more accurate investment decisions.

Customers can get professional help when they encounter problems during the implementation process, which has enhanced our trust in cooperation.

Special Product Packing

Packaging machines are widely used in the packaging of tobacco. The cigarettes are collected and arranged in a certain amount and direction and then sent to the small bag packaging machine. Usually 20 pieces at a time. The machine puts the cigarette branch into the pre-prepared paper, and then folds and seals to form a common hard box or form a common hard box or seal. Soft bag cigarette. This process may include wraps of trademark paper, inner lining paper, and transparent paper. Small cigarettes will be further packaged into strip boxes. The box packaging machine puts a certain number of small bags (usually 10 packs) into a larger box and then seals it.

In the end, the strip may be wrapped in a layer of transparent film to protect products and prevent tampering. At the same time, there will be necessary information such as brands, warnings, and component descriptions on the packaging.

What Can We Pack ?

- Application

Related Product

SembsunPack —— Your One-Stop Packing Machine Solution Supplier

Solve more packaging problems for you, Welcome to our Packing Tour.

We will update the spot to our customers at any time. After receiving the deposit, we usually have a production cycle of about 20 days.

No, we will suggest that you add functions according to your needs, not that the more functions, the better the packaging machine.

Of course, before each packaging machine is shipped, our staff will debug according to the customer’s materials and packaging to ensure that the customers are familiar with work as soon as possible after the delivery.

It is necessary. In addition to the instructions of the packaging machine, we also provide an electronic file instructions to make it easy for customers to check on their mobile phones. In addition, we also provide installation videos to ensure that our customers are installing the machine correctly