Sembsun Automatic Bottle Filling Machine

- Quantitative Control

- Semi Automatic Filling Machine

- Fully Automatic Bottle Filling Machine

- For granular, powder, and liquid products Packing

- Single-head multi-head unloading, high speed, and stability

What are the Semi and Automatic Filling Machine

The semi-automatic filling machine provides a weighing and feeding device. You can put the bulk products to be packaged into the filling machine, and then perform a weighing and automatic feeding device. Manual cooperation is required for sealing. Usually in micro-small businesses, with high flexibility and good stability.

First of all, the Fully automatic filling machine provides a higher automation program, which is suitable for merchants with sufficient budgets. The fully automatic filling machine can be equipped with a bottle unscrambler, labeler, capping machine, carton machine, seal packing machine, capping bottle machine, and other machines to make the packaging process more intelligent, reduce labor input, and greatly improve production efficiency.

Among them, semi-automatic filling machine applications include: semi-automatic sesame oil filling machine, semi-automatic flour filling machines, semi-automatic laundry detergent filling machine, semi-automatic milk filling machines, semi-automatic capsule filling machine, manual bottle filling machine, etc.

Fully automatic filling machines include: liquid filling machine, powder filling machine, bottle filling machine, water filling machine, oil filling machine, counter pressure beer bottle filler, water filling bottle machine, paste filling machine, honey filling machine, cream filling machine, pill filling machine, juice filling machine, perfume filling machine, lip gloss filling machine, cosmetic filling machine, etc.

Sembsun Semi Automatic Filling Machine

Semi automatic filling machines quantitatively weigh, reduce errors, and are faster than manual, cost-effective choices.

Suitable for granular product packaging, including preserved fruits, nuts, puffed foods, Chinese medicinal materials, rice crust, beans, and rice. You can quickly adjust the weight. It can be filled with cans and bags at the same time.

Suitable for granular product packaging, including feed, rice, cement, dryer, fertilizer, and hardware. Wide weighing range, high adjustability, improved labor efficiency. It can be filled with cans and bags at the same time.

Suitable for packaging powder products in bottles and bags, manual control switch, strong practicality, can be packaged flour, protein powder, seasoning, etc.

Suitable for bottle packaging powder products, including flour, protein powder, seasoning,servo motor, stable and efficient.

Semi auto liquid filling machine suitable for liquid packaging, common liquids with good fluidity such as sesame oil, bottled water, juice, laundry detergent, honey, sauce, etc.

Suitable for liquid packaging, with magnetic pump unloading, can be packaged perfume, juice, alcohol, shampoo, cream, 502 glue and other volatile liquids.

Suitable for granules, including white sugar, rice, salt, beans, seasonings, washing powder, plastic rubber, and other quantitative weighing packaging.

The weighing device is coated with Teflon, which can package relatively sticky products, such as: candies with sugar, dough, pancakes, pumpkin cakes, etc.

Sembsun Automatic Liquid Filling Machine for Bottle

Sembsun Bottle liquid filling machine creates packaging solutions for different liquid products

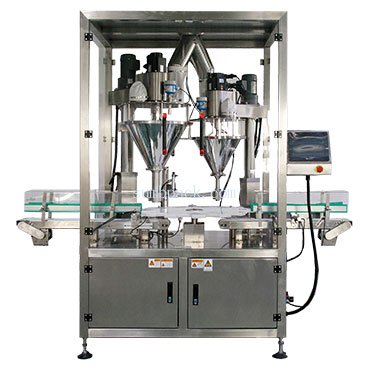

Sembsun Automatic Powder Filling Machine for Bottle

Powder filling machine for bottles Packaging makes the packaging look good and makes it easy for customers to store.

Sembsun Automatic Granular Filling Machine for Bottle

Granular filling machine, quantitative packaging of products of different sizes, saving time and effort.

Our Filling Machine Advantage

Provide professional responses to customers on technology and price

Strictly abide by standards and conduct multiple quality inspections

Integrity and fair service to every new and old customer

Free training and corresponding video guidance

4-Head Liquid Filling Machine with Automatic Filler for Canned Food

Fully automatic filler device, we match different numbers of unloading ports according to customers, accurately matching.4-head precision filling horse mouth cans, convenient high-speed packaging, matched with capping machine, the finished product is tightly sealed

Double Heads Powder Filling Machine with Pouch Filling Equipment for Protein

Vertical Pouch Filling, more different liquid unloading, directly reaches the bottom of the bottle to unload.Dual-head powder feeding, secondary feeding packaging accuracy, can be applied to expensive food or medicinal materials

4 Linear Weigher Automatic Filling Equipment for Rice

Automatic can feeding device, quickly reach the machine position.Linear weighing particles, feeding and filling, enhance brand awareness, good sealing effect.

Sembsun Liquid Filling Machine for Bottle Packaging Manufacturer

A good filling production line is inseparable from stable technical support. From design to welding, from CNC lathe to grinding, and then to debugging, step by step, we are serious about every step of the process, in order to give our customers more assured quality.

Whether it is a single filling machine to a filling production line, which also includes the selection scale, electric heating aluminum foil sealing machine, capping machine, labeling machine, and bottle collecting machine, we will provide customers with professional instructions. Customized packaging production lines provide customers with a stable source of goods, reliable credit, and a manufacturer of safe packaging.

Sembsun Bottle Filling Machine Applications

PET bottle filling technology dominates the filling industry. If your bottle is made of PET, whether it is a granular, liquid, or powdered product, you can use different weighing devices to fill the bottle.

Our common PET filling granular products include popcorn, nuts, dog food, and cereals; powders include milk powder, protein powder, and seasoning powder in aluminum cans.

Beverages are divided into non-alcoholic and alcoholic products. Aseptic filling technology has revolutionized beverage packaging, including PET and glass bottle filling.

Common ones include carbonated beverages, low-concentration alcoholic beverages, juices, aseptic milk packaging, etc.

The packaging of hazardous chemicals requires corrosion resistance and sealing. The requirements for filling equipment are higher. The fully automatic filling line requires high-precision filling, followed by sealing, which prevents chemical products from leaking out of the storage room.

All kinds of cosmetics have the characteristics of high viscosity. Our six-axis manipulator accurately positions and realizes the rapid switching of bottles of different specifications from 50 to 1000 ml. At the same time, the servo motor is used to drive the filling valve, and the minimum filling volume can reach 0.1 ml, which is suitable for 1 ml ampoule packaging.

The filling of vials must reach IOS 5 clean environment to ensure that the produced drugs are not contaminated, which is an important basis for subsequent use. On the other hand, the current lyophilized powder filling also adopts the ampoule filling method.

Granular drugs are filled in brown glass bottles or plastic bottles according to different characteristics. The device for counting granules needs to be accurate to avoid inconsistent dosage. Different filling bottles are matched with different filling systems, and OEM customization is supported.

Filling Machine Applications

- Bottle Filling Types

Related Product

Bottle Filling Machine Production Line

Whether it is liquid, granules, or powders, we provide a complete packaging production line. Let automation be close to life.

1. What products need to be packaged?

2. How many grams per bottle? Or how many milliliters per bottle?

If it is juice, ask whether there are particles, whether it is hot-filled or cold-filled, etc.

3. Bottle size and pictures/bottle design drawings

Based on the complete production line of the filling machine, we propose the following functional equipment options, which can be selected according to your own needs.

– Bottle sorting – Measuring and unloading – Blow dryer – Capping machine – Aluminum film sealing – Capping/pressing – Labeling – Material sorting

If edge pasting is required, is the labeling full label or small label, and the size of the label.

Fluid: refers to liquid materials that flow freely in a pipe at a certain speed under gravity, with a viscosity of 0.001-0.1Pa·s, such as milk/soft drinks/alcohol, etc.

Semi-fluid: In addition to gravity, it also requires external pressure to flow in the pipe, with a viscosity of 0.1-10Pa·s, such as condensed milk/syrup/ketchup, etc.

Viscous fluid: cannot flow under its own weight, must rely on external pressure to flow, with a viscosity of more than 10Pa·s, such as sauce/jam, etc.

Piston filling machines are suitable for more viscous liquids and liquids with good fluidity, such as water, honey, sauces, etc.

Liquids with good fluidity can be filled with magnetic pumps.