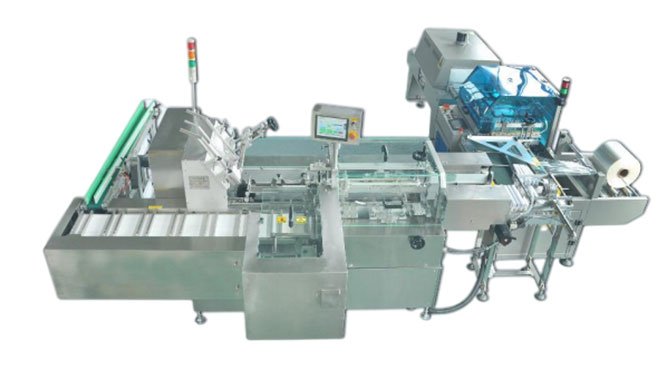

Automatic Carton Packing Machine

- Customer Customized Service

- Controlled by PLC Microcomputer

- Automatic Loading, Folding, Inserting

- Automatic Unpacking, Packing and Sealing

- Compatible with Many different sizes of Paper Boxes

What is Carton Packing Machine

The fully automatic box packing machine has integrated functions and automated program packaging. It has the functions of automatic box opening, automatic box packing, automatic box folding, ear folding, buckle insertion, and automatic finished product output ear. It adopts human-machine interface control, simple operation, and convenient maintenance. At the same time, adding other packaging equipment makes the packaging production line more intelligent and humane. At the same time, adding carton sealing machine packaging equipment makes the packaging production line more intelligent and user-friendly.

For example: in combination with a flow wrap packing machine, the product is first bagged and then transported to the carton box packing machine by a conveyor belt and then boxed for secondary packaging, saving manpower to put the product back on the shelf. After the fully automatic cartoning machine, the product is added with a heat shrink film machine, and the end-stage sealing and heat shrinking are completed through the flipping mechanism and the sorting mechanism. It is often used for buying facial masks, food, and health products.

Horizontal Carton Packing Machine

Fully automatic cartoning machine solutions, your preferred leader in packaging machines.

Horizontal standard cartoning machine integrates carton opening, loading, folding, and sealing.

304 stainless steel appearance, durable, can adjust multiple boxes of different sizes.

New Design carton packing machine, speed can reach 40-60 per minute

Extended box packing machine, packaging products are more extensive, can pack inner and outer boxes of facial masks.

Vertical Carton Packing Machine

Vertical Compact design, Saves Space.

One-touch rotation, automatic box opening.Applied in car bulbs, LED bulbs, switches and sockets, and filters.

Rotary station, Applied in round bottled medicine, food-stuff, cosmetics, etc. packing into the square box.

Advanced PLC control system with Hot melt adhesive machine, applied in 502 glue, oral liquid without tray, lined cosmetics.

304 stainless steel shell, applied in the industry for pharmaceutical, food, cosmetic, electronic, and paper box vertical automatic forming packaging.

One-Stop Packing Solutions with Carton Packing Machine

Professional Development of New Products

Upgraded and Simplified Appearance

Stable Spot Manufacturing

Professional Pre-sales and After-sales

Automatic Carton and Packaging Machine Production Line

This set of equipment can organize the two products through line conveying, and automatic boxing, and then after sorting, it is sent to the big box for three packaging, automatic unpacking, packing, and sealing.

Advantages :

First, it can be compatible with a certain range of paper boxes at the same time.

Second, glue spraying and box sealing is simple and efficient.

Third, it can meet the automatic sorting and packaging of two paper boxes of different sizes.

Fully Automatic Cartoning, Labeling and Packaging Production Line

This equipment can be compatible with 4 different sizes of cartons at the same time. It is a packaging machine that integrates automatic box opening, loading, folding, inserting, and secondary inserting. It is controlled by PLC computer, with automatic alarm and fault prompt. It adopts human-machine interface control, which is simple to operate and easy to maintain. It can also replace products regularly according to different user requirements. Installation and debugging are simple and fast. Common application ranges include blood pressure monitor product carton packaging machines.

Fully Automatic Bagging, Cartoning, Packaging and Packaging Production Line

This equipment is a customized whole-plant packaging production line. The product is first bagged by the pillow packaging machine, cut and sealed, and then grabbed by the robot arm and put into the material grid of the high-speed cartoning machine conveyor belt to complete the cartoning output, and at the same time, the opening, packing, and sealing machine is added to complete the cartoning. This machine is a fully mechanical linkage transmission, mainly relying on gear transmission. The whole machine design uses the synchronous movement of the material through and the push rod to complete all the packaging processes of the spray glue carton and the ear carton packaging. It has high transmission accuracy and stable machine operation.

Fully Automatic Bagging,Cartoning,Heat Shrink Packaging Production Line

This equipment is connected to the flow wrap packaging machine at the front end. After the bagging is completed, the conveyor belt transports the product to the cartoning machine, which seals and forms the box. Through the flip mechanism and sorting mechanism, the rear sealing and heat shrinking are completed. It is suitable for paper box packaging machines of various varieties and specifications. It is controlled by a PLC microcomputer, with an automatic alarm and fault prompt. It has the characteristics of human-machine interface control and simple operation.

Automatic Carton Packing & Plastic Shrink Packaging Line

This production line is mainly composed of a cartoning machine and a heat shrink packaging machine, equipped with a PLC programmable controller and a human-machine interface operation panel, which can automatically realize the processes of packaging into boxes, sealing boxes, and POF film heat shrink packaging. It can also be connected with an L Bar heat shrink packaging machine and a case packing machine to form a complete production line to meet the needs of mass production.

This equipment is suitable for the entire process of paper box products such as facial masks, food, health products, and daily chemicals, including boxing, PE, PVC, and POF heat shrink packaging.

Fully Automatic Flow Wrap Packaging Cartoning Packaging Production Line

This production line is mainly composed of a paper-feeding pillow packaging machine and a cartoning machine. After the pillow machine has been packaged once, it is transported to the cartoning machine to automatically complete the automatic operations of opening, packing, and sealing.

This equipment is suitable for the whole process of packaging food with trays, hardware, daily chemicals, and other items with trays with film pillow packaging and then sealing them into boxes.

Fully Automatic Box Opening, Packing and Sealing Machine for Carton

A cartoning machine is designed specifically for arranging and packing products into large boxes. It can pack the individually packaged products into large boxes again, saving manpower and increasing packaging speed.

Fully Automatic Cartoning, Packaging and Sealing Machine for Bottle

This equipment packs the products into bottles. It is commonly used for cans, water bottles, red wine, and other bottled products. It can be matched with labeling machines, capping machines , and flow wrap packing machines to improve the automation process.

The supporting equipment can be added and adjusted according to customer needs, providing a complete packaging solution.

Carton Packing Machine Working Principle

First Station: Box loader

Second Station: Form Bag

Third Station: Left Folding

Fourth Station: Material insert

Fifth Station: Right Folding

Sixth Station: Floding Done

Seventh Station: Forming

Eighth Station: Finished Goods

It is suitable for automatically packing liquid bottles, eye drop bottles, ear drop bottles, toothpaste, medicine bottles, blister-formed capsules and tablets, aluminum-plastic packaging blister plates, and similar items into cartons.

Also suitable for various cartons, such as airplane boxes.

Other Packaging Equirments with Carton Packing Machine

- The function of warning malfunction.

- Equipped with a package machine for precise control.

- Multiple functions: Use fixed nozzle assembly or mobile handgun.

- Double-layer stainless steel filter net to catch the impurities to extend the machine’s life.

- The melting tank, dispensing nozzle, and hose could be heated orderly to avoid the nozzle overheat and to reduce the carbonization

- Weekly timer for setting the time to turn on and off the machine automatically by requirements.

- The function of keeping warm as a “Stand-by” status to reduce the carbonization of the hot melt and meet the envelopment-friendly purpose.

- The precise piston pump is effective to continuously supply glue while pumping.

The flow rate depends on the viscosity of hot melt adhesive.

Carton Packing Machine Details

- Machine Electrical parts

- Hot melt adhesive machine

| No. | Name | Qty |

| 1 | PLC | 1 |

| 2 | touch screen | 1 |

| 3 | Frequency converter | 1 |

| 4 | solid state relay | 1 |

| 5 | Switching power supply | 1 |

| 6 | Intermediate relay | 16 |

| 7 | Photoelectric switch | 3 |

| 8 | Push box cylinder | 1 |

| 9 | Pushing cylinder | 1 |

| 10 | Press box cylinder | 2 |

| 11 | Material sensor switch | 1 |

| 12 | The electromagnetic valve | 5 |

| 13 | Motor | 1 |

| 14 | Proximity switch | 1 |

| 15 | Emergency stop switch | 1 |

| 16 | Encoder | 1 |

| Item | Specifications |

| Tank Capacity | 5 liter |

| Max Melting Rare | 7kg/HR |

| Max Operation Temp | 200℃ |

| Max Viscosity | 8000CPS |

| Available Hose | 1-2 |

| Dimensions(mm) | 520length X 339width X 475 height |

| The height of cardboard stacking | 4Kg/c㎡ |

| Melting Tank Powder | 2000Watt |

| Machine’s net weight about | 31KG |

| Powder Requirement | 220V 50/60Hz |

Related Product

Carton Packing Machine Solution Supplier

Your Leader Packing Machine Manufacture in China!

Your box ears need to have pre-designed creases, so that the packaging effect will be better.

Bulk products are more suitable for horizontal cartoning machines, while vertical cartoning machines generally package single products.

The cartoning packing machine integrates box opening, loading, box folding, and carton sealing. The machine can replace the workload of 6-10 workers.

The carton packing machine can box different materials by using different (widened) pushers

The carton packing machine feed slot can hold about 300 boxes.