Sembsun Automatic Twist Tie Packing Machine

- SUS3 stainless steel material

- The wire cutter of the equipment is made of tungsten steel, which has a long service life

- The height of the conveyor belt can be adjusted (about 10cm)

- Fully automatic, can be connected to the belt, and can be produced on the assembly line

Configuration

- Equipment materials and configuration

- Factory Showcase

1. The outer packaging of the equipment is made of SUS3 stainless steel.

2. All parts of the equipment are made of SUS stainless steel, aluminum, and copper.

3. The electrical configuration of the equipment,

- Delta PLC,

- Delta display,

- Keyence fiber optic photoelectric sensor.

- Airtac cylinder,

- Taiwan brand stepper motor

- Other electrical appliances are made of Delixi, Chint and other brands.

4. The gold wire cutter of the equipment is made of tungsten steel and has a long service life. The warranty period is three years, and free replacement is available if there is any problem during the warranty period.

5. The conveyor belt uses PU food grade belt.

Automatic Bread Twist Tie Tying Packing Machine Parts

PVC Conveyor Belt

The twist tie machine is equipped with a high-performance PVC conveyor belt, which is easy to clean and maintain daily. It supports stepless speed regulation and can accurately adjust the transportation speed according to packaging requirements to achieve efficient and stable transportation.

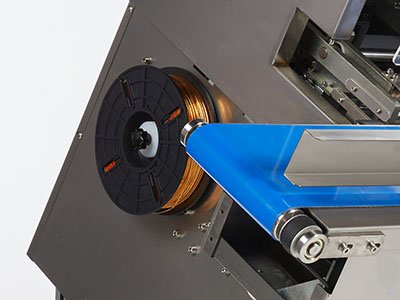

Efficient Reel Device

The automatic twist tie machine uses an efficient reel device. The cable tie reel is easy to install and can be quickly loaded, saving time and effort. The reel device is combined with a precision tension system to ensure that the cable tie is evenly tightened, firmly tying all types of bag openings to effectively prevent loosening or falling off.

Intelligent Touch Screen

The automatic twist tie machine is equipped with an intelligent touch screen control system with an intuitive and friendly interface. Users can easily set strapping parameters through the touch screen to achieve precise adjustment. The operation process is simple and clear, and you can quickly get started without professional training. The system supports multi-language switching (Chinese/English/Spanish, etc.) to meet global production needs

Sembsun Service Term

Technical Data

- Machine Data

- Bag Type

| Model | Air Source/P (MPa) | Capacity (per minute) | Power Supply | Bag Width | Machine Weight | Appearance (CM) |

| D-450-370 | 0.6 | 20-36 | 220V/0.75KW | 100-360/mm | 150kg | 115*110*110 |

Operation Video

✔ Applicable: soft packaging such as baking paper bags, transparent film bags, kraft paper bags, etc.

✖ Not applicable: hard box packaging or metal foil packaging.

Stepless speed adjustment (such as 20-36 times/minute) through the touch screen or knob to adapt to different production line speeds.

Food-grade PP cable ties, paper strapping ties or degradable materials, in line with food safety standards.

Common problems: cable tie jam, sensor misjudgment.

Preventive measures: Regularly lubricate the guide rail and clean the photoelectric sensor.

Support PLC signal docking, can be integrated into the automated production line, and realize one-stop operation of packaging-bundling-labeling.