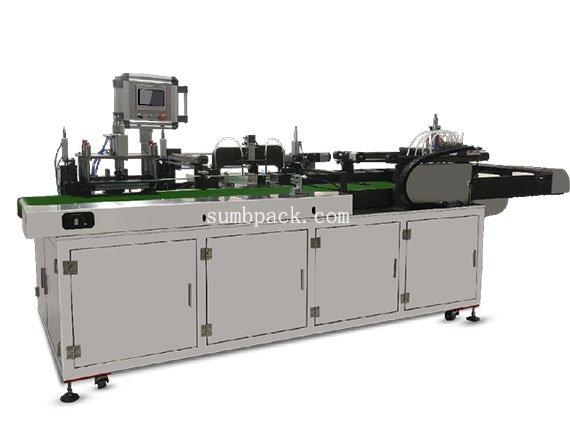

Sembsun Automatic Push Bagging Machine

- Flat Push Premade Pouch Packing Machine

- Accurate material feeding, optimized working environment

- Reduce transportation time, improve production efficiency

- Automated rotary sealing machine

How is Automatic Push Bagging Machine Work?

Our factory for customers to design a single-push and double-push design, which double-push bagging machine is widely used. Specially designed for prefabricated bag type, with zipper bag type, using automatic feeding, material handling, bagging, pushing, sealing, output, and other packaging forms, compact structure, beautiful packaging, sealing firm and beautiful. Adopting a PLC touch screen can adjust the packing temperature and speed according to the packing material, product thickness and length. The Servo motor is safe and stable. The operating system language can be Spanish, French, Korean, Russian, Japanese, Arabic and other local languages.

1. Large packing range, convenient adjustment, and quick conversion between various specifications.

2. Adopting a flat push type, high speed, smooth operation, and modularization of the packing area makes it more convenient to change products.

3. A multi-station bag feeding structure can be adopted for various types of pre-made bags (flat bag, M bag, standing bag, four-side seal bag, etc.).

4. Adopting an opening fixture, according to the height of the material, can open enough space to ensure that the material can be put into the bag smoothly, and at the same time, it can maintain the position of the prefabricated bag without deviation.

Sembsun Automatic Push Bagging Machine Types

Suitable for food, medicine, hardware, daily necessities, cosmetics, hygiene products, and other products of the Premade bag packaging.

5-28bags/min, Bagging method:Direct drive/Clamp Push

40-45bags/min, Bagging method:Direct drive/Clamp Push

5-25bags/min, Bagging method:Direct drive/Clamp Push

5-25bags/min, Bagging method:Direct drive/Clamp Push

15-40bags/min,Packing specification:(100-280)x(100-200)x(30-100)mm(LxWxH)

Our Automatic Premade Pouch Bagging Machine Advantage

Horizontal feeding

Adjustable material size

Efficient and firm sealing

Clean and easy to handle

Direct drive Clip Push

The automatic bag pushing function can quickly and continuously push the bag to the designated position for filling, sealing and other subsequent processes, which greatly reduces the manual operation time and improves the production efficiency.

Safety performance motor

Servo motors, inverters, PLCs (Programmable Logic Controllers), heating modules, and solid state relays in bagging machines

Servomotor.

High precision control: servo motors enable precise position, speed, and torque control to ensure the accuracy of the bagging machine operation. Energy-saving and efficient: consumes energy only when needed, and does not consume power when there is no load, helping to save energy and reduce emissions.

Frequency inverter.

Flexible speed regulation: The motor speed can be adjusted according to the production demand, allowing smooth speed changes in the process and optimizing energy use.

PLC (Programmable Logic Controller)

Heating Module: The heating temperature can be precisely controlled through the closed-loop control system to ensure the sealing quality.

Solid State Relay: Compared with traditional electromagnetic relays, solid state relay has no mechanical contact, long life, and no maintenance. Low noise, low power consumption.

The above components work together to allow the bagging machine to operate efficiently, accurately and reliably.

Horizontal bag opening

Horizontal bag opening automated bag pushing reduces the opportunity for workers to come into direct contact with high-speed running mechanical parts, reducing the risk of workplace accidents and ensuring operator safety.

Strong adaptability: the bag pushing device of modern bagging machines is usually designed with good adaptability, able to handle bags of different sizes and materials to meet diversified packaging needs.

Continuous operation ability: not subject to artificial fatigue limitations, push the bag machine can continue to work stably, especially in a long time, the advantages of mass production are significant, to ensure uninterrupted production.

Automatic Feeding Bag Packing Machine Details

- Specifications

- Finished Product Display

| Model Specification | Automatic Feeding Bag Packing Machine(Single push) |

| Bag Size | Width: 50-150mm Length: 50-300mm (supports non-standard customization) |

| Packaging Material | Composite materials such as composite film, aluminized film, polyethylene/polypropylene, etc. |

| Bagging Method | Direct push Clamp push |

| Packaging Speed | 5-25 bags/minute |

| Power Supply | Three-phase four-wire 380V 50/60Hz 6.5Kw |

| Gas Consumption | Recommended matching w-1.0/101 air compressor》0.5-0.8m3/min 300-500L/min |

| Machine Weight | 900Kg |

| Machine Size | 2900mm×2470mm×1728mm |

Conventional vacuum packaging cases are mainly food and ready-to-eat food. Sutiable for stand-up bags, zipper bags, paper bags (surface covered with paper), four-side sealed bags, three-side sealed bags, aluminum foil bags, paper bags (surface covered with paper), nylon bags, etc.

Related Product

Automatic Push Bagging Machine Solution

Intermittent sealing is better, ensuring the beauty of the seal and avoiding leakage.

1. Put on the belt 2. Reserve space 3. Pre-development and bag support 4. Unloading 1 5. Unloading 2

6. Unloading 7. Straightening 8. Rotate to vacuum

Room temperature 10°C-40°C 30-90% RH, no dew, no corrosive gas, no dust, and other harsh environments