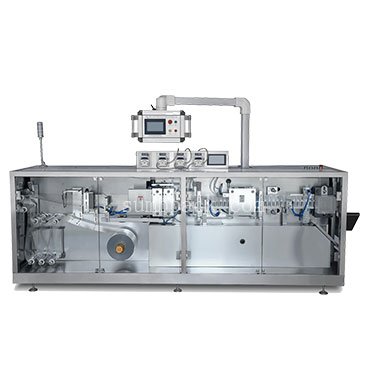

Sembsun Automatic Ampoule Filling Sealing Machine

1. Sheet forming, environmentally friendly and recyclable materials

2. Imported 316 stainless steel filling contact material

3. Automatic unwinding, film slitting, beautiful finished products.

4. Safe and stable servo motor

5. Liquid pump filling system with accurate measurement and small error.

Sembsun Ampoule Filling and Sealing Machine Working

The ampoule filling machine is a packaging machine that integrates unwinding, sheet forming, filling, sealing, batch numbering, tail cutting, punching, and slitting, which are completed automatically by the program. The finished package does not drip, foam, overflow, or draw, and it is the first choice for many ampoule packaging.

Many merchants choose this machine to expand the sales market and improve its convenience.

We have corresponding models of ampoule filling and sealing machines for different disposable products.

PLC control, stepless frequency conversion adjustment operation. The electronic peristaltic pump filling system packs liquid medicine with little precision error, and all interfaces are made of 316 material.

Health care products filling machine. It is suitable for a variety of film roll filling styles, precise filling, a variety of functional beverages with different viscosities, and anti-drawing during filling and sealing.

The upgraded version of 240, imported electrical components make the ampoule filling machine work more stably. High-quality stainless steel 316 material can directly fill sterilized liquids, in line with GMP standards.

PLC control, stepless frequency conversion. The servo motor pulls the film more accurately. The bottom is printed with a steel stamp to print the date and production batch number.

Double-sided aluminum film roll slitting, cover film can be printed with LOGO pattern for standardization, made of PP material, resistant to high temperature cooking, in line with the packaging needs of pasteurized merchants.

Our Ampoule Filling Sealing Machine Advantage

The machine has a compact and beautiful appearance and can be designed according to customer needs. It is suitable for daily chemicals, food, medical and chemical products.

Applicable to a variety of ampoule filling, bottle shapes, cone, oval, stand-up plastic bottles, etc., support customer customized styles and shapes.

One-to-many filling and sealing machine can meet the needs of high-volume manufacturers and can be quickly put into operation.

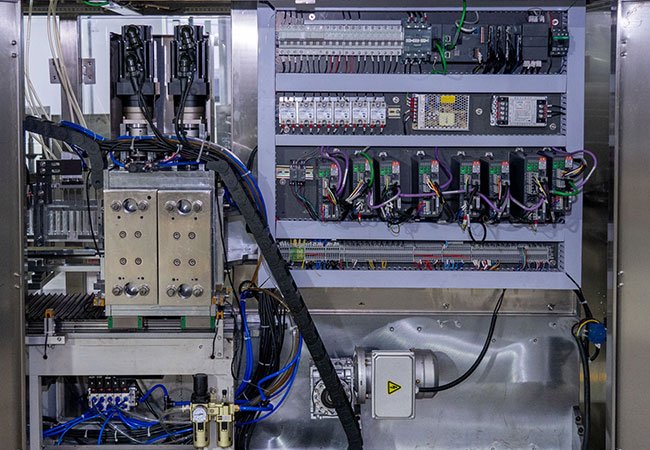

The stable performance of imported electrical appliances ensures the stable performance of the machine at high speed. At the same time, there are safety protection devices to make the work efficient and safe.

Plastic Ampoule Filling and Sealing Machine-Roll Film cutting

Our roll film material supports PET/PE PVC/PE (0.2-0.5) x120mm, and high-precision CNC cutting technology ensures that the cutting error of each piece of hard plastic roll film is ≤0.1mm, without burrs or deformation, perfectly adapting to the packaging needs of Plastic Ampoule of different specifications, and supporting special-shaped cutting customization. The cutting process is sealed and dust-proof, and it is equipped with a medical-grade 316 stainless steel die to eliminate the risk of secondary contamination.

Electronic Peristaltic Pumps

We use the intelligent closed-loop control technology of electronic peristaltic pumps, with a filling volume error of ≤±0.5% and microliter-level precise filling (starting from 0.01ml), ensuring that the dosage of each disposable essence and liquid medicine is consistent. The liquid only contacts the food-grade silicone tube, without friction of metal parts. It can be cleaned in 3 seconds to change other liquid product.

Compatible with a variety of disposable specifications from 1mL to 30mL. Whether it is beauty samples, medical reagents, or high-end skin care products, it supports 0-500ml/min filling volume adjustment. It can be tried in more packaging markets.

Medical-grade 316 filling equipment

Our filling and unloading parts are made of high-quality stainless steel 316L, and the outside of the machine is all SUS304 stainless steel. The physical properties of 316L are sterile and corrosion-resistant, and have a long resistance to pitting corrosion.

Stable and Efficient Motor Combination

From controlling the PLC point machine and servo motor, we use high-speed, high-precision, high-end motion controller. Stepless frequency conversion speed control. Among them, the servo motor controls the film pulling device more accurately, which can provide safe protection performance in the face of long-term work.

Our Ampoule Filling Sealing Machine Factory Support

We can customize Ampoule solutions for customers based on their production capacity, plant size, and speed. We have a design team to design Ampoules for different products for you and provide suggestions on roll film materials.

Secondly, we have a stable roll film material supplier, who can design Ampoule styles for free, provide you with free trial opportunities, and provide you with different needs at different stages.

We provide a stable production chain, with close connection between the design department and the production workshop, to provide customers with complete production lines in a timely manner.

Special Packaging Film Case

A variety of roll film materials are available for customers to choose from. PET/PE PVC/PE(0.2-0.5)x120mm, PET/AL PET/PE

Ampoule Filling Sealing Machine is used with a labeling machine. The finished ampoule can be labeled to increase the design aesthetics and brand promotion

Ampoule Filling Sealing Machine is combined with a cartoning machine to combine individual items together for easy sales and statistics.

Our Ampoule Filling Sealing Machine Packaging Solutions

- Ampoule Shape Types

Different shapes of disposables, different ml designs.

Related Product

Ampoule Filling Sealing Machine Manufacturer-You want to Know More.

It is gradually being used widely in the medical industry, pharmaceutical production, chemical industry, pesticide, food and cosmetics industries.

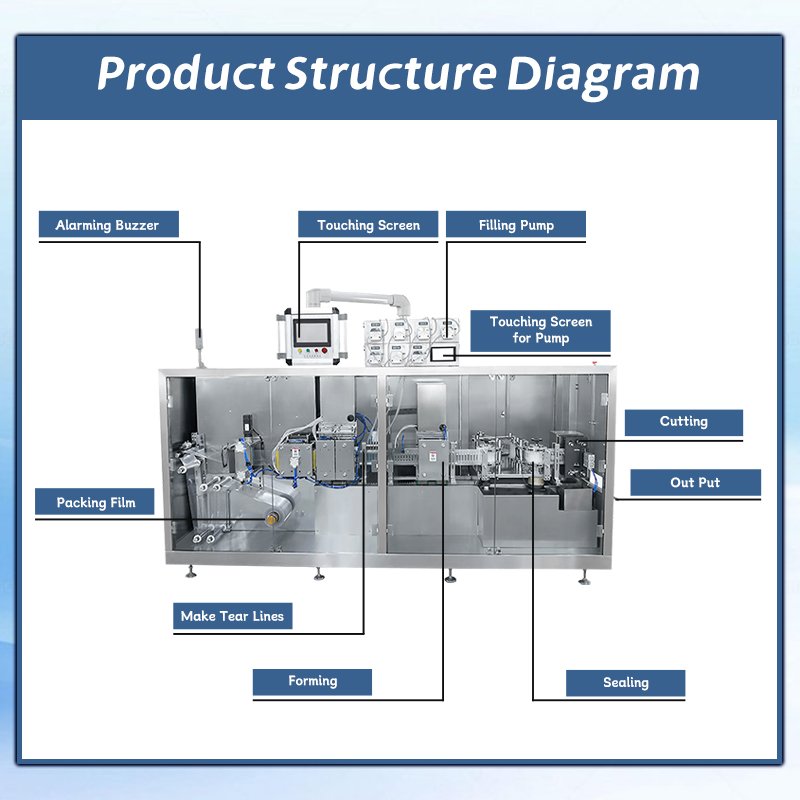

There are 10 components, you can see from the picture that there are Alarming Buzzer, Touching Screen, Filling Pump, Touching Screen for Pump, Cutting, Packing Film, Out Put, Make Tear Lines, Forming, and Sealing.

It has a wide range of uses and is used in all walks of life in our daily lives. For example:

Pharmaceutical industry: oral liquid, health care products, physiological saline, lotion, cough syrup, Chinese medicine oral liquid, etc.

Chemical industry: perfumes, car perfumes, human milk, shower gels, shampoos, essential oils, detergents, hand soaps, inks, etc., paste products, etc.

Pesticide industry: foliar fertilizer, plant growth regulator, herbicide, emulsifiable concentrate, rodenticide, and other chemical products;

Food industry: linseed oil, castor oil, olive oil, enzymes, honey, Dendrobium, and so on.

There are two types of ampule sealing methods about ” Tip Seal Method” and the “Pull Seal Method”

Tip-sealing is to melt the tip of the bottle mouth directly at high temperature through a hydrogen-oxygen flame or an oxyacetylene flame after the ampoule is filled with liquid medicine so that the glass softens and closes naturally to form a smooth dot-shaped seal. This process does not require additional stretching, and it is naturally formed by relying on the surface tension of the glass.

Application scenario: It is often used for packaging small-volume (such as 1-2mL) ampoules, especially suitable for chemical reagents or injections that do not require a high sealing appearance, and the cost is low.

Pull-sealing involves mechanically stretching the bottle mouth while heating the flame during sealing, forming a slender glass wire neck. The neck is then fused twice, and finally, a closed-end with wire drawing marks is formed. This requires precise control with automated equipment, which is costly.

This ampule sealing machine mainly packages products with hard plastic appearance, and the weight is generally within 1ml-200ml. The packaged products can stand and have certain pressure resistance.

Liquid filling machines generally have bottle and bag filling. Bag filling generally has prefabricated bags and relatively soft roll film, and the weight range of packaging is relatively large. Liquid prefabricated bag packaging machines include premade pouch packaging machines, liquid roll film packaging machines include vertical form fill seal machines, and filling machines can be used for can packaging.

Which packaging machine to choose is determined by the finished product effect required by the customer. You can tell us according to your needs.

We support fully customized mold development (samples or drawings are required), and adjust packaging length (10-50mm), diameter (5-30mm) and other parameters. Laser marking or inkjet printing modules are optional to achieve personalized identification such as LOGO, batch number, QR code, etc., with an accuracy of ±0.1mm.

Our compatible PP/PE/PET ampoule sheets with a thickness range of 0.1-0.5mm support special-shaped cutting (such as round tubes, square boxes, etc.). The material does not require additional coating or heating to soften, and the equipment comes with a temperature control module to automatically adjust the molding temperature. Special specifications can provide free sample services to verify adaptability.