Sembsun Single Head Rotary Spout Pouch Filling Capping Machine

An Automatic Filling and Capping Machine is an integrated packaging equipment for premade pouch doypack filling and capping

- Small footprint

- Automatic bag filling

- Suitable for small business development needs

- Used for liquid stand-up pouch packaging with spout

Sembsun Automatic Single Head Rotary Spout Pouch Filling Capping Machine

The single-head desktop stand-up spout pouch filling and capping machine can package two types of bags: oblique-spout and stand-up pouches with middle spouts. It can directly discharge materials from the spout and seal the bag without opening it in advance.

- Handles products with varying viscosities, from watery liquids to thick pastes.

- Compatible with spouted pouches of different sizes and shapes, depending on the application.

- Ideal for industries looking to use eco-friendly and flexible spout pouch packing machines.

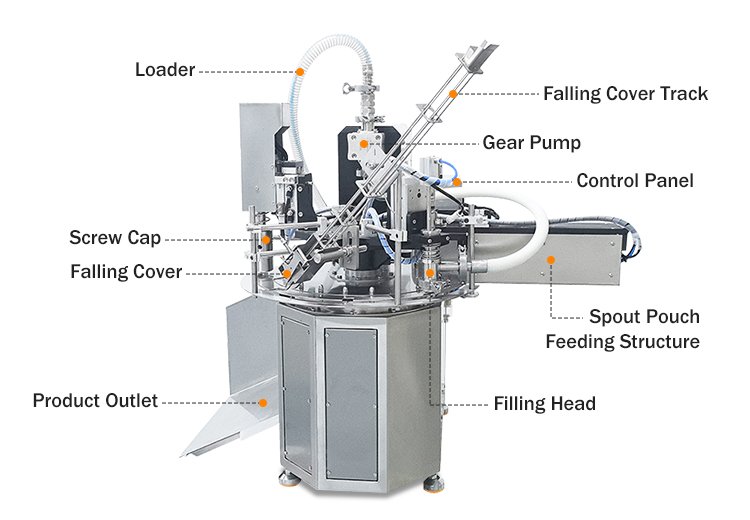

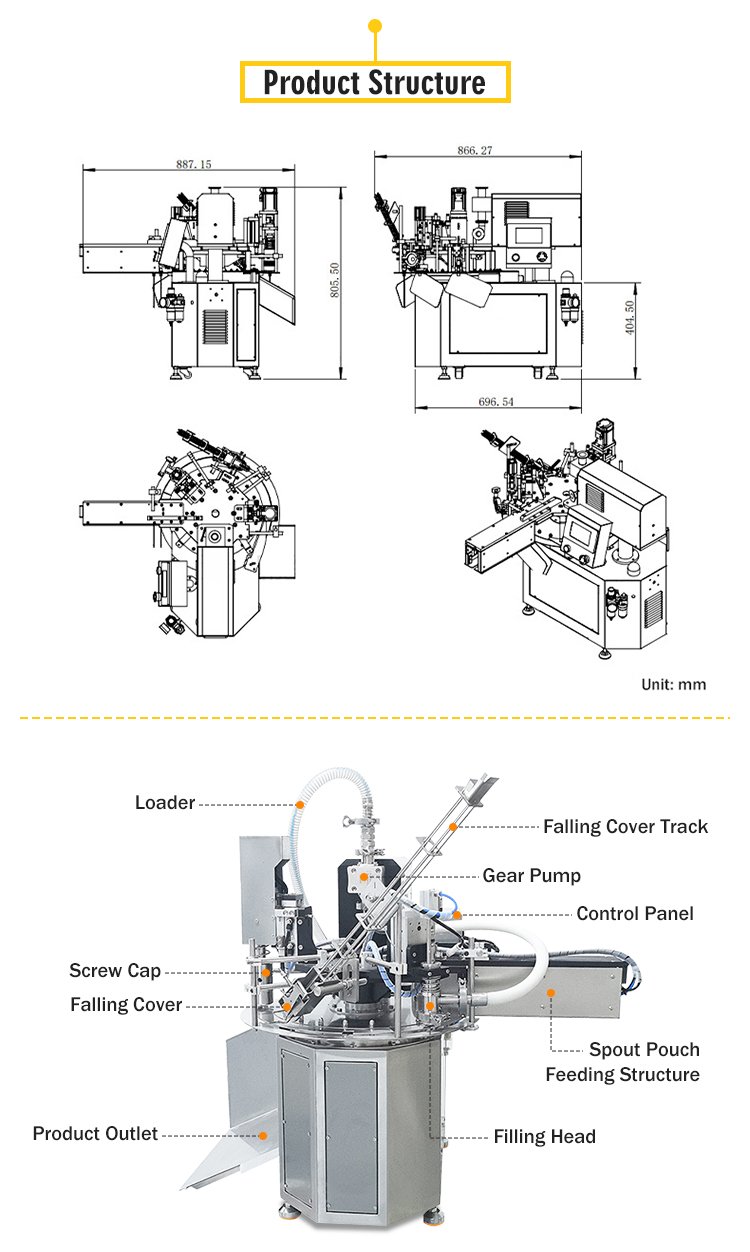

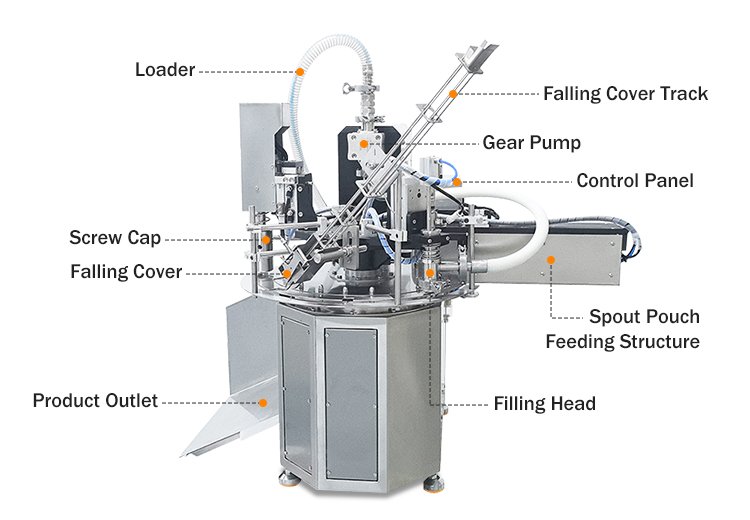

Rotary Spout Pouch Filling and Capping Machine Configuration

- Product Structure

- Spout Pouch Types

- Parameter

- Major Dispositions

This machine is specially designed for filling and capping stand-up bags with spouts, such as center and slanted. It can be operated according to your needs.

| Voltage | 220V 50HZ | Noted | |

| The power of the machine | 5Kw | ||

| production Speed | Within 2L: 600-900 bags / Hour | Speed is related to material capacity and viscosity | |

| Fall cover way | Translation cover | ||

| The way out | Turntable push bottle | ||

| Turntable power | 370W | Cam splitter |

| Solenoid valve | Yadek | |

| Relay | Schneider | |

| PLC | IMS | |

| Touch screen | Kunlun Tongtai | |

| Photoelectric sensor | Panasonic | |

| Lid vibration plate | 1 set | |

| Machine size mm about length | 887*width 450*height 790 | |

| weight | 300KG | |

| Frame material | 304 stainless steel | |

| Material contact | 304 stainless steel | |

| Wheels | Fuma wheel | |

| Aluminum parts | Aluminum plate anodized | |

Sembsun Single Head Rotary Spout Pouch Filling Capping Machine

Precise Placement of Spout Bags

Our packaging machine manually puts the self-supporting bag with a spout into the bag slot and installs it. The machine will drive each bag to the drinking hole, and then rotate to the filling station for filling. Mostly used in automatic filling capping machines, Jelly Juice Filling Capping Machine, Spout Pouch Filling Capping Machine, Spout Pouch Jelly Juice Filling Capping Machine.

Filling into Spout bags

The filling station is in direct contact with the material and uses a 304 stainless steel lower spout. The entire filling is driven by a servo, and the standard filling volume is 500ML-2000ML. We can also make adjustments based on customer needs.

Lower Cover Device

The lids are arranged one by one in an orderly manner on the vibration plate track designed by us. After the filling of the spouted stand-up pouch is completed, it rotates to the cover-down station, and the lids are attached to the top, waiting for the capping station to seal. Our vibration plate design reduces the work of manual lid-down and protects the product from secondary contamination.

316 Non-steel Gear Pump

Our equipment is made of 316 grade non-ferrous steel, rot resistant, conforms to CMP standards, and the packaging of the equipment we use is carefully selected. Simultaneous illumination with high precision and easy cleaning.

Our Spout Pouch Sealing Machine Service Advance

Single Head Rotary Spout Pouch Filling Capping Machine Applications

- Spout Pouch Filling and Sealing Machine for Food and Beverage

- Cosmetics and Personal Care

- Pharmaceuticals

- Household and Industrial Products

The Single Head Rotary Spout Pouch Filling and Capping Machine is designed for packaging products in spouted pouches. It is ideal for filling and capping liquid and semi-liquid products. Below are the types of products it can handle:

- Juices, smoothies, and flavored drinks

- Sauces such as ketchup, mayonnaise, mustard, and salad dressings

- Purees and baby food

- Dairy products like yogurt and milk

- Soups and broths

- Cooking oils and syrups

- Liquid soap and shampoo

- Hair conditioners

- Body lotions and creams

- Liquid medicines

- Health supplements (e.g., liquid vitamins)

- Oral care liquids like mouthwash

- Detergents and liquid cleaners

- Automotive products like antifreeze and windshield washer fluid

- Liquid fertilizers or pesticides

Related Machine Model

Pre made Spouted Pouch Filling and Capping Machine

Spout Pouch Filling and Sealing Machine Applications

It is also equipped with a 60L gear pump. The whole machine is made of 304 stainless steel. The filling device uses a 316L servo gear pump. The filling head has a built-in air-blowing device (to prevent the material from drawing), and the system has a built-in feeding device.

The packaging speed of the Single-head Spouted Pouch Filling and Capping Machine can reach 40-45 bags/min for 100ml; 500ml: 30-3540-45 bags/min; 750ml: 20-3040-45 bags/min; 1000ml: 20-25 bags/min.

The speed of the Double-head Spouted Pouch Filling and Capping Machine can reach 20-80 bottles/min.

This does not require professional operation. Our machine uses Huichuan PLC console, which can be operated by simply changing the appropriate language. The working principle of the whole machine is manual bagging and anti-covering to the sorting plate. Spout Pouch Filling Capping Machine automatically feeds bags, automatically fills, automatically drops and locks the lid and automatically discharges the bag. After simple training, one operator can operate 3-6 machines, which is efficient and stable.

Generally, we can pack spout stand up pouches with bag width and bag length within 50-330mm. The range of the lid can be tested by adjusting the track. If your spout stand up pouch is special, you can send us a video and we will provide an improved solution.

First, we test the viscosity range of the liquid through the video or physical object provided by the customer. Secondly, we use a gear pump, which has strong self-priming power and can overcome the height difference of different liquids to a certain extent.

However, if your liquid is very special, we can replace the appropriate pump head according to the characteristics of the liquid.